The on site crankshaft grinding machine is manufactured and marketed by RA Power Solutions having more than four decades of experience in extending the services of crankshaft grinders and polishing the crankpin and main journal.

The on site crankshaft grinding machine is manufactured having a range starting from 30 mm to 700 mm in terms of diameter. The smaller diameter of the on site crankshaft grinding machine up to 100 mm is more suitable for grinding and polishing crankshafts used in construction equipment, compressors, pumps, etc.

The crankshaft grinding machine having a range of 100 mm and above is ideal for undertaking crankshaft repair, crankpin grinding, and polishing of marine engines and heavy-duty rotating equipment.

We are the leading provider of onsite crankshaft grinding machines and polishing, Insitu turbine shaft Grinding and Polishing, Rotor Shaft Grinding and Polishing, Portable crankshaft grinding machines, crankshaft grinding and repair.

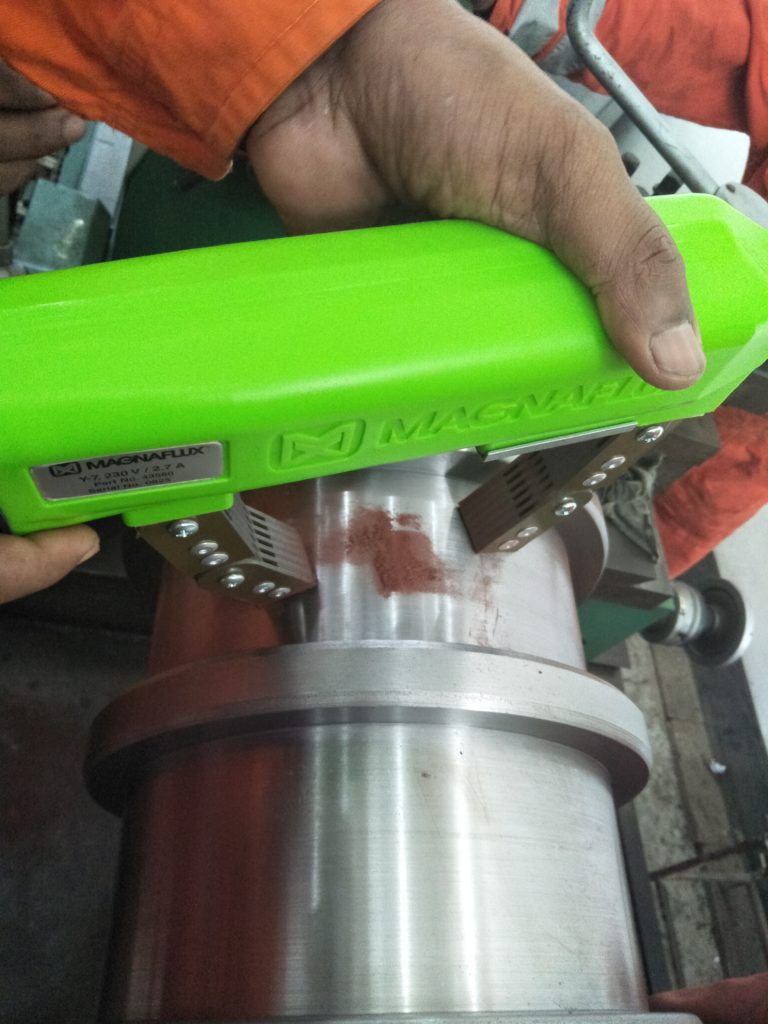

Grinding of Crankshaft

RA Power Solutions has recently supplied a crankshaft grinding machine ranging from 220 to 260 mm in Diameter to a Bangladesh-based client. This is the first onsite crankshaft grinding machine to be sold in Bangladesh. Several diesel-generating sets are in operation and have a large population of vessels passing through the various ports of Bangladesh.

The onsite training on the operation and maintenance of the crankshaft grinding machine is of great help to the buyers as within a short time of 1 week the technicians learned how to operate the onsite crankshaft grinding machine and maintain it.

Since the bench-type crankshaft grinding machines are outdated and are replaced by compact, portable, easy-to-operate in-situ crankshaft grinding machines. It has bought a revolution in this area as the cost of repair of crankshaft grinders and downtime of the marine engine has been reduced drastically.

The maintenance of the crankshaft grinding machine equipment is easy and is explained in detail to the technicians operating the machine.

For manufacturing an on site crankshaft grinding machine, the raw material is selected to keep the machine weight to the minimum and to meet the stress at the time of grinding and polishing of the crankshaft. The main parts of the crankshaft grinding machine are manufactured of titanium and ferrous alloys.

The easy operation, low price, and training on the job for the buyer’s technicians have made it popular and to date, more than 70 crankshaft grinding machines have been sold all over the world.

At RA Power Solutions, we prioritize customer satisfaction and strive to deliver top-quality services that exceed your expectations. Our on site crankshaft grinding machine is just one example of our commitment to providing innovative solutions for engine repair and maintenance.

Contact us today to discuss your crankshaft grinding and repair requirements and grinding of crankshaft. Our knowledgeable team will be happy to assist you and provide a tailored solution to ensure the optimal performance of your engine. Trust us for all your crankshaft grinding needs.

For more information regarding, crankshaft grinders, crankshaft grinding services, and crankshaft grinding equipment, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.