A diesel power plant based in northern India having 10 nos. of 12.3 MW Wartsila diesel generating sets reported severe causality involving one of their Wartsila generators.

RA Power Solutions team of technicians rushed to the power plant with the measuring instruments and onsite crankshaft grinding equipment to assess the cause of the breakdown.

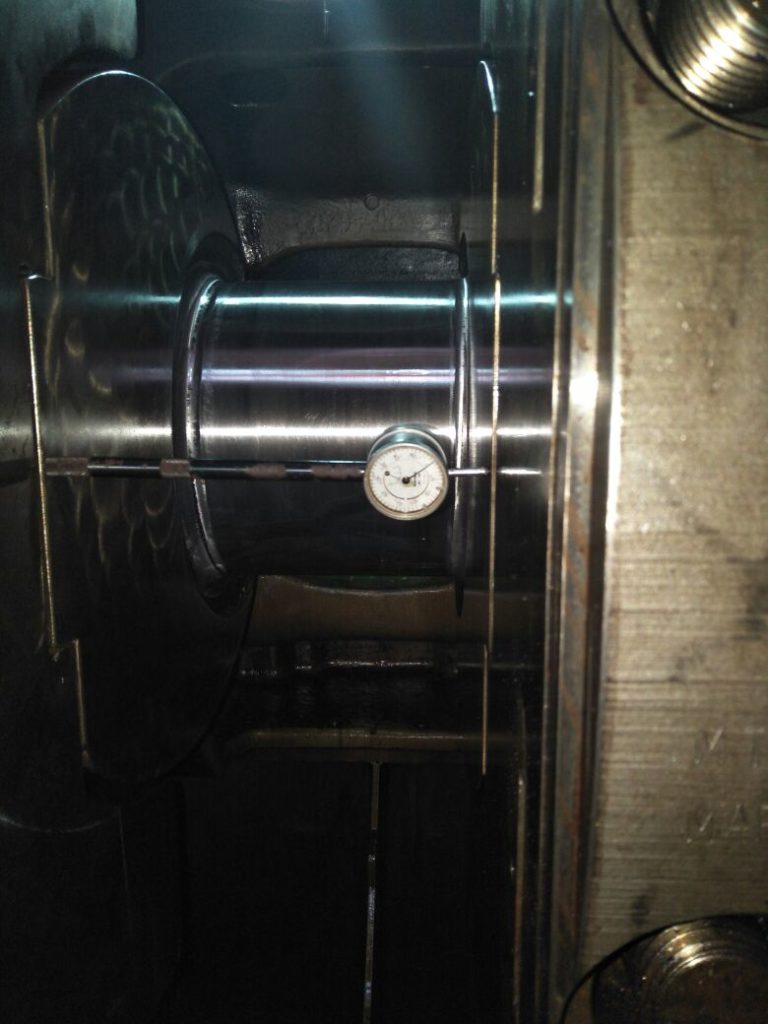

On undertaking the detailed inspection of the crankshaft including dimensional check, hardness test, and MPI for crack and deflection, it was observed that one of the crankpin journals was damaged due to the failure of a big end bearing.

The following were the main observations:

- Taper and ovality in the crankpin were observed as 0.70 mm.

- Due to the failure of the bearing, deep line marks were visible.

- Hardness and MPI tests were done, and no cracks were observed.

RA Power Solutions used the latest design of onsite crankshaft grinding machine having almost no vibrations. The crankpin was undersized by 1.5 mm maintaining the tolerance within 10 microns. Our technicians took only 18 hours to complete the Crankshaft repair from the time of the start of the preliminary inspection, grinding, and final inspection. The repair of the crankpin in such a short time was possible due to the latest technology onsite crankshaft grinding machine used and the experience of our technicians. The engine was assembled and is performing satisfactorily.

RA Power Solutions has four decades of experience in working on crankshafts of high-capacity main and auxiliary engines. The technicians are trained in the factory to execute the repair of the crankshaft strictly as per the manufacturer’s specifications and tolerances.

We are the leaders in this field and our prices are the most competitive.

For more information on Crankshaft Grinding Machine, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.