RA Power Solutions understands the importance of white metal babbitt bearings irrespective of their application for high-capacity diesel engines, alternators, turbines, pumps, etc.

We specialize in white metal bearing repair and manufacturing of new white metal babbitt bearings, pads, and guide bearings up to the bore size of 1500 mm.

Repair of Old Bearings:

To successfully repair old bearings, the following process is adopted by RA Power Solutions:

- Removal of old white metal with controlled temperature.

- A thorough inspection of the steel bearing shell for any variation in hardness, blow holes, and pitting.

- MPI of the steel bearing shell to check any hairline crack

- Visual inspection for any distortion in the original profile to avoid complications at the time of assembly.

- Metallurgical inspection of old white metal used in the original bearing, selection, and improvement of white metal grade to enhance the life of the bearing.

- Preparation and rebabbitting of white metal are done by a centrifugal system. This ensures uniform dense babbitting of white metal.

- A thorough inspection of the bearing after rebabbitting for bonding and crack.

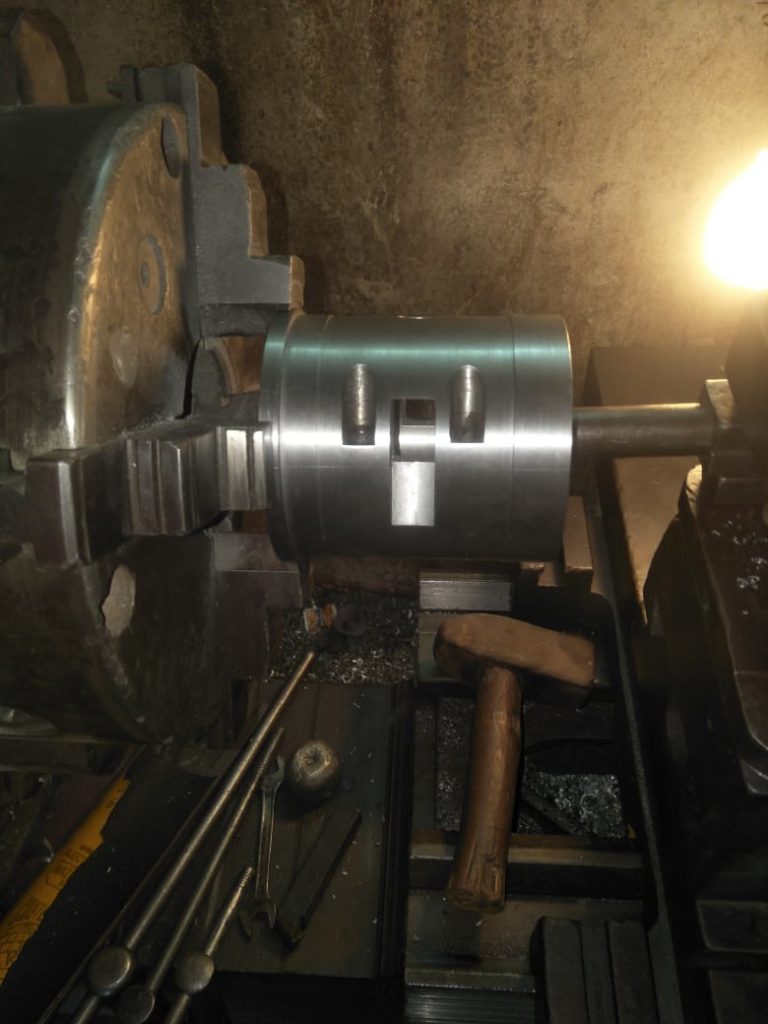

- Rough and final machining in a CNC machine shop fully dedicated to maintaining close tolerances.

Manufacturing of New White Metal Babbitt Bearings:

- We manufacture new white metal babbitt bearings for all applications up to 1500 mm bore size. It has the following features:

- We can manufacture the white metal babbitt bearing strictly as per the drawing provided by the client.

- In the case of non-availability of drawing which is common for the old pieces of equipment, bearing can be developed as per the sample provided.

- We accept smaller quantities of white metal Babbitt bearings for manufacturing.

Bearing Remetallic Services

We are experts in extending Bearing Remetallic Services. The complete procedure of bearing remetallic services offered by us is standardized. Right from a selection of Babbitt white metal composition to the inspection of bare bearing shell, Rebabbitting of white metal by centrifugal process, machining, and final inspection.

The Bearing Remetallic Services are offered by us in the minimum possible time in comparison to other manufacturers. We are also considered to be the lowest in price.

All bearings are manufactured by centrifugal process delivering the bearings of international standards with long life.

We have manufacturing facilities based near New Delhi International Airport and extend white metal bearing repair services to our clients based all over the world. The bearings are custom cleared and collected, brought to our factory for rebabbitting, and re-exported after repairs and rebabbitting in a short time.

It is common for us to undertake the repair of alternator bearings, turbine, and engine bearings. All the bearings irrespective of whether new or repaired are thoroughly inspected and calibrated in-house by our experienced technicians.

The bearings are supported with a metallurgical report giving the details of the material composition of white metal. A dimensional report covering the critical dimensions is also shared.

For more information, regarding white metal bearing repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.