A continuous process industry based in western India using 2 units of Wartsila 6R32 for their power requirements reported a breakdown of one of the Wartsila 6R32 diesel generating sets.

RA Power Solutions team of senior technicians was deputed with portable inspection instruments and an onsite crankshaft grinding and polishing machine. The following observations were reported on the inspection of crankpins:

I) On investigation of Wartsila diesel generating sets, it was observed that it was a clear case of lube oil pump failure.

II) All 6 crankpins were found damaged.

III) Inspection in detail was carried out. The gist of this is as follows:

a) Crankpin no. 1 ovality of 0.76 mm. No cracks were observed. Hardness within limits.

b) Crankpin no. 2 ovality of 0.54 mm. No cracks were observed. Hardness within limits.

c) Crankpin no. 3 ovality of 0.26 mm. No cracks were observed. Hardness within limits.

d) Crankpin no. 4 ovality of 0.49 mm. No cracks were observed. Hardness within limits.

e) Crankpin no. 5 ovality of 0.29 mm. No cracks were observed. Hardness within limits.

f) Crankpin no. 6 ovality of 0.62 mm. No cracks were observed. Hardness within limits.

After an initial inspection of the crankshaft, it was decided to undertake the repair of the crankshaft of Wartsila 6R32 by grinding the crankpin.

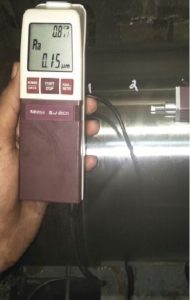

Three nos. of pins were ground undersized by 1mm and balance 3 were undersized by 0.5 mm. The taper, ovality, and surface finish have been maintained far better than the manufacturer’s recommendations. The above job was executed in a record time of 6 days.

For more information regarding marine and auxiliary engine crankshaft repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.