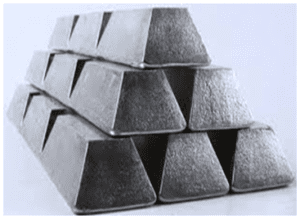

RA Power Solutions manufactures and exports white metal Babbitt ingots and ingots of pure lead, tin, aluminium, zinc alloy, white metal etc for different applications like oil and gas, mining, steel plants, shipping, etc.

The Ingots, offered by us, include Lead Alloy Ingots, Pure Lead Ingots, Zinc Ingots, White Metal Ingots and Aluminium Ingots. To make these products, we thoroughly process Lead, Zinc, Aluminium & Antimony, which are sourced or imported from the best producers in the world. Thus processed metals and alloys are altered in Pure Lead, Lead Alloys & Zinc Alloys shaped into Ingots and exported to many countries across the globe.

All these years, we have advanced production techniques and the ingots supplied by us are strictly as per client specifications or as per the international norms.

We are known all over the world for our quality.

WE SUPPLY INGOTS OF FOLLOWING ALLOY:-

- Tin Solder Sticks

- Zinc Alloy Ingot

- White Metal Ingots

- Aluminium Ingots

- Lead Alloy Ingots

- Pure Lead Ingots

- ZAMAC Alloy Ingot

- Zinc Ingots

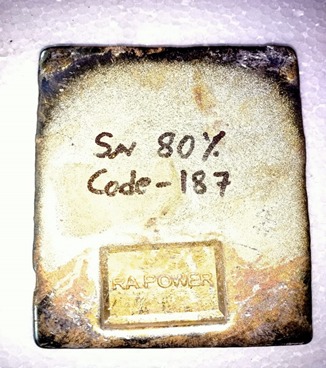

THE INGOTS OF BABBITT WHITE METAL SUPPLIED BY THE US HAVE THE FOLLOWING BROAD SPECIFICATIONS:-

- Sb (Antimony): 8% to 20%

- Sn (Tin): 3% to 80%

- Cu (Copper): 0.2% to 2.0%

- Pb (Lead): Remaining

Ingots babbitt white metal, Alloy Ingots are largely exported by us all over the world including Madagascar, Oman, Qatar, Philippines, Bahrain, Srilanka, Bangladesh, Myanmar, Turkey, Nigeria, Greece, Saudi Arabia, UK, Dubai, Malta, Cyprus, Singapore, Malaysia, Colombia, Indonesia, Hong Kong, Spain, Netherlands, Dubai, Portugal, Estonia, Morocco, Belgium, Vietnam, Canada.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.).

Mr. Shahani is a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy and Shipping industry. He is a Technical Adviser to many shipping and heavy industries across the globe.

Mr. Shahani is one of the most enthusiastic professionals and he has all the brilliance of an exemplary leader. Mr. Raj Shahani is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more information regarding babbitt white metal ingots, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.