Babbitt white metal has an important role in satisfactory performance of bearings. The selection of Babbitt white metal is done keeping in view various technical factors. Few of them are given below:-

- RPM of shaft.

- Load characteristics on Babbitt white metal bearing

- Type of lubrication oil used.

- Bonding characteristics required.

- Cleanliness and type of filters used.

- Maintenance schedule of the bearing.

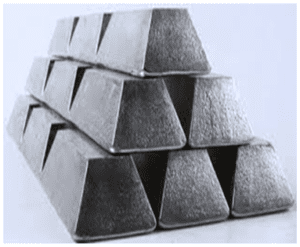

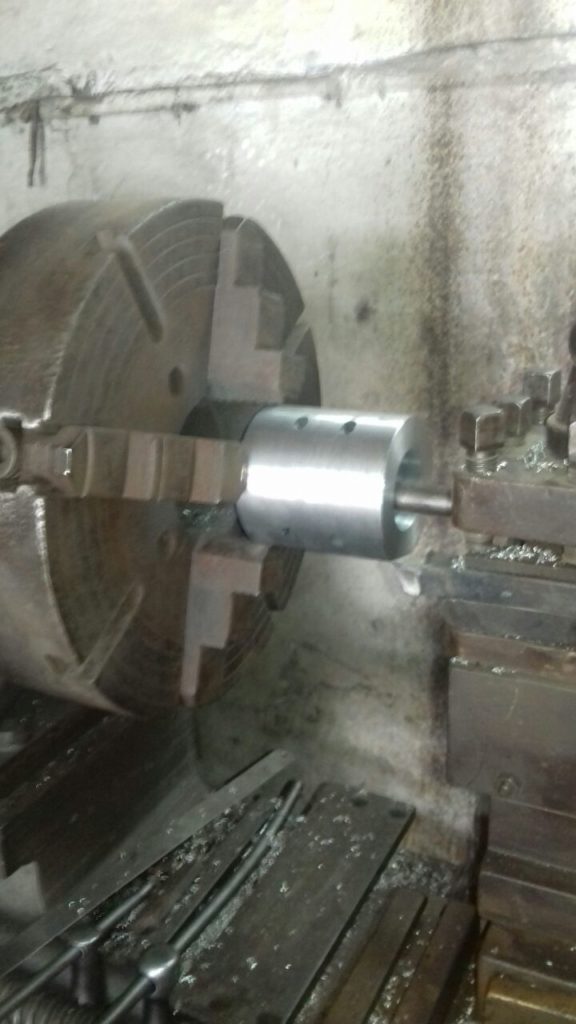

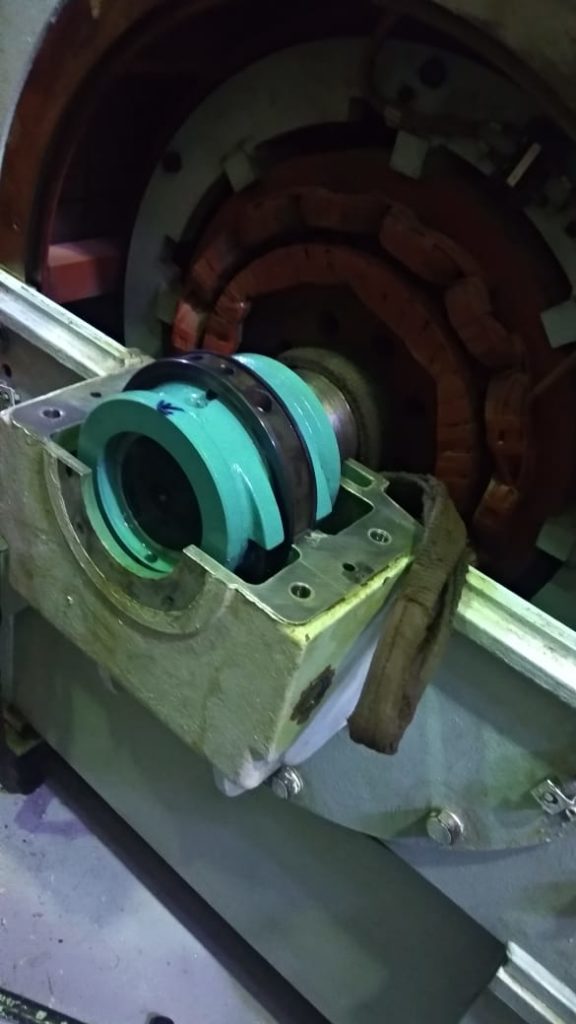

RA Power Solutions Pvt. Ltd. manufactures Babbitt white metal in different grades strictly as per the requirement of the client. The Babbitt white metal is manufactured in our modern facilities having digital control on the metallurgical requirements, temperature and various other aspects required to produce quality white babbitt metal. We manufacture Babbitt white metal broadly of tin based and lead based. We provide babbitt bearings repair and babbitting services.

Tin based Babbitt white metal

The tin based Babbitt white metal is the material which contains more than 80% tin alloy. It may also contain a lesser percentage of antimony, lead and copper. Some of the tin based Babbitt metals are free of lead mainly for the equipments used in the food industry.

The tin-based Babbitt metal has the inherent property to provide low wear and tear due to low friction resistance.

Lead-based Babbitt white metal

Lead-based Babbitt white metal is also a commonly used bearing material as it contains 75% or more of lead alloy. It also contains tin and antimony. The lead-based metal has excellent corrosion, capabilities and is used for marine applications.

Generally speaking, lead based Babbitt white metal is used for the shaft RPM of 100 to 1000 maximum.

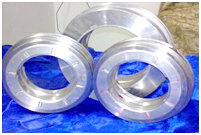

Babbitt White Metal with Tin % of 83.2

Babbitt White Metal Manufactured & Exported

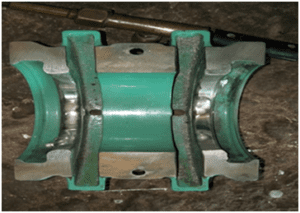

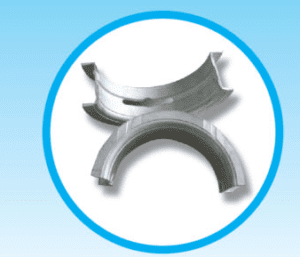

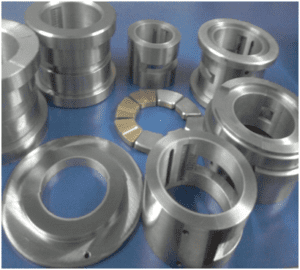

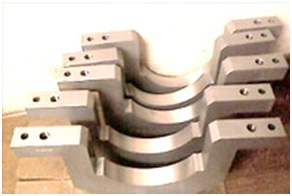

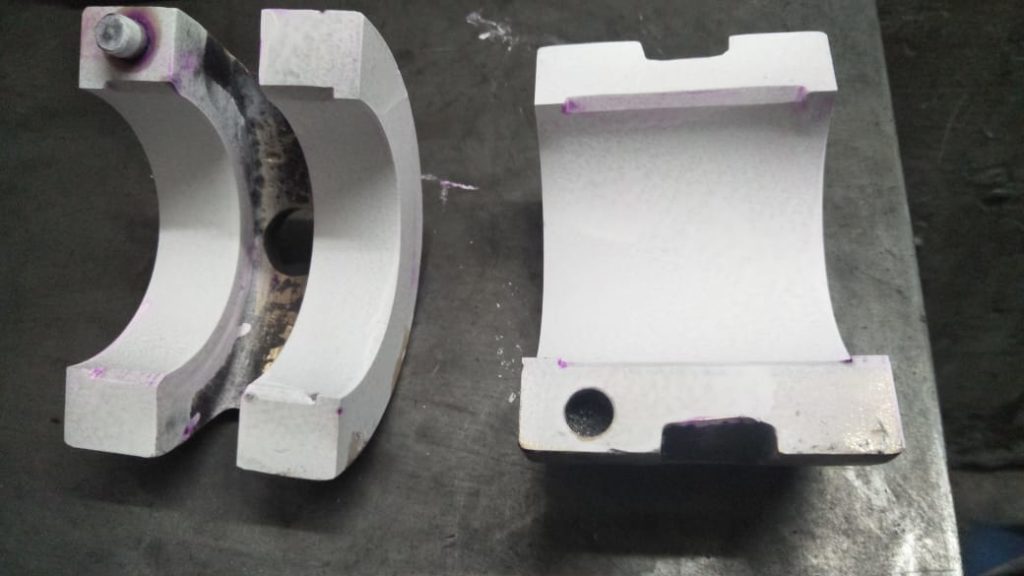

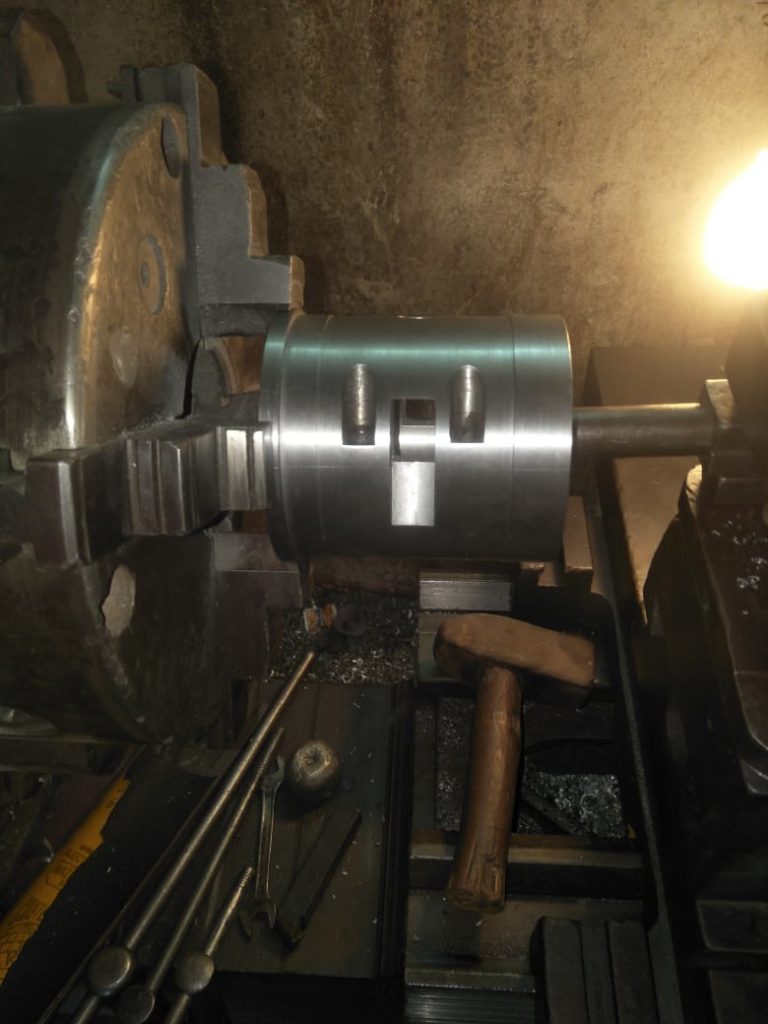

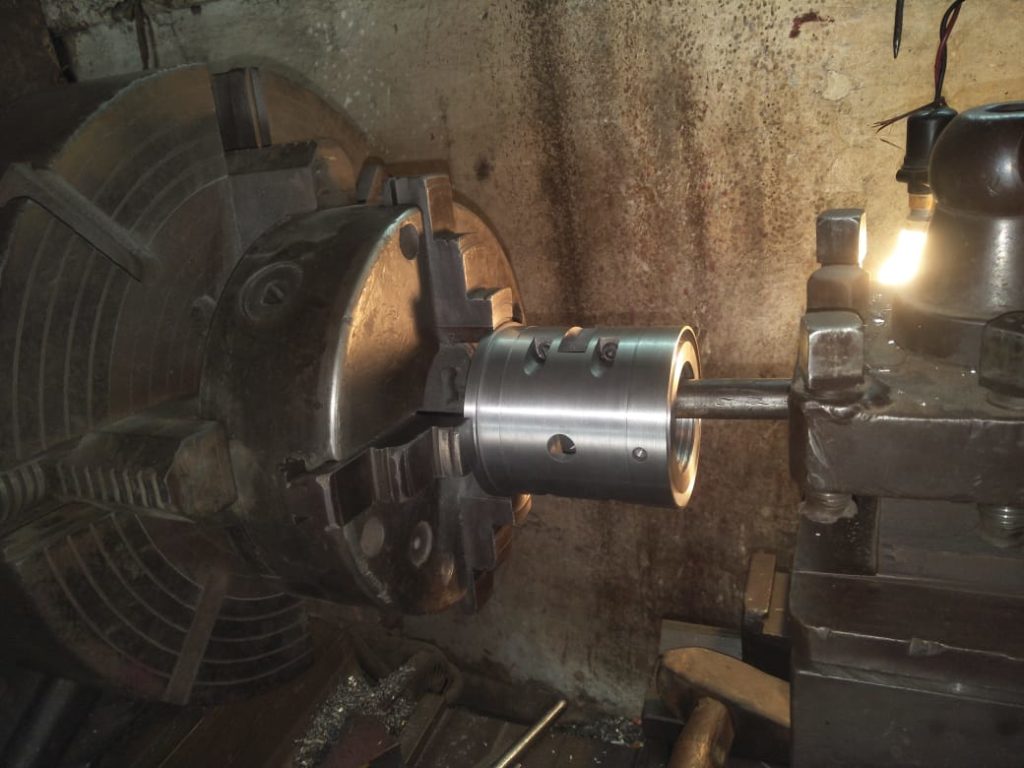

The Babbitt white metal manufactured by us is also used for the manufacturing of new bearings and Rebabbitting of old bearings which is undertaken in our workshop. Presently, the Babbitt white metal is exported to various countries including Ecuador, Bolivia, Colombia, Saudi Arabia, etc.

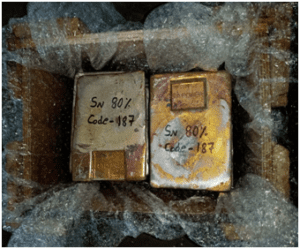

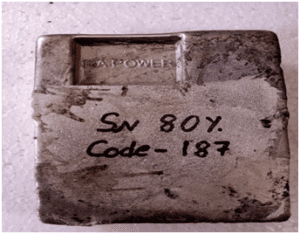

Export of Babbitt White Metal with 80% Tin Babbitt White Metal Ingots

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions). He has forty years of experience in the field of engine repair and is a technical adviser to various shipping and heavy industries based all over the world.

For more information related to leading Babbitt metal, Babbitt bearings repair, and babbitting, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.