RA Power Solutions with over four decades of experience is at the forefront of the technology of design, development, manufacture, and repair of white metal Babbitt bearings.

The manufacturing of new bearings and repair of old white metal Babbitt bearings is done for customers from all sectors of industries and applications like an electric motor, fans, pumps, marine, diesel engines, turbines, alternators, rolling mills, etc.

Manufacturing of White Metal Bearings | White Metal Babbitt Bearings

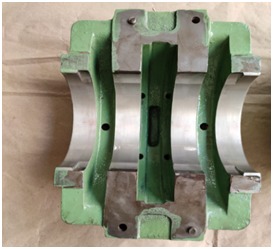

The bearings up to the diameter of 1500 mm are manufactured by us. The babbitting of white metal is strictly undertaken by centrifugal process and in a controlled temperature environment. It is proven that babbitting of white metal by the centrifugal process has various definite advantages over static babbitting.

The machining of the bearings is undertaken strictly as per the drawing or a sample submitted by the end user. The in-house installation of CNC equipment facilitates us to maintain the bearing dimensions with close tolerance which enhances the life of not only the white metal Babbitt bearing but of the rotating shaft on the white Babbitt bearing assembled.

Development of White Metal Babbitt Bearing by Reverse Engineering

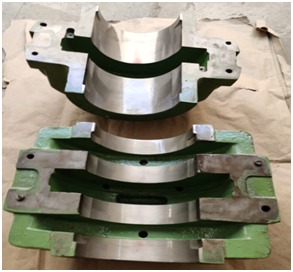

At times, there is a requirement for the development of bearings based on the old bearings available in the plant. This is common when the original equipment manufacturer has discontinued manufacturing of the main equipment or the white metal Babbitt bearing. RA Power Solutions engineering department develops a drawing of the damaged or worn out bearing based on the dimensions which can be drawn from the old worn out or damaged bearings provided by the client.

The dimensions that are not clear due to damage and old worn-out bearings are incorporated in the drawing based on our experience of four decades in the design and development of bearings. We develop and manufacture the white metal Babbitt bearing based on the old bearing with a 100% guarantee.

White Metal Babbitt Bearing Repair Services

The repair of old and damaged white metal bearings is undertaken by us from 50 mm to 1500 mm bore size. We worldwide enjoy the reputation of executing repair in no time. In case of an emergency.

Various quality checks are undertaken while repairing the old bearing which include the following:-

- Removal of white metal from the old bearing at a controlled temperature.s

- Inspection of bearing shell for crack after removal of white metal.

- Hardness check of the naked bearing shell and removal of hard spots by scooping technology.

Metallurgical test of white Babbitt metal and use of higher grade of Babbitt white metal.

We would like to strongly express that the bearings repaired by us after rebabbitting of white metal have a higher life cycle than the original bearings. In case of an emergency, we have the capacity even to repair the bearings within 24 hours.

Quality Control

RA Power Solutions is an ISO 9001:2015 accredited company for the design, development, and manufacturing of white metal Babbitt bearings and associated engine components.

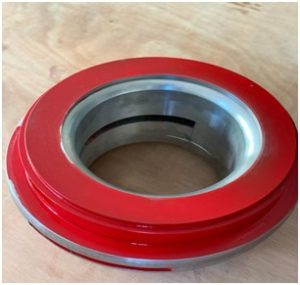

BEZ Alternator Bearings After Machining

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions). He has more than forty years of experience in the field of engine repair and is a technical adviser to various shipping and heavy industries based all over the world.

For more information, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.