Crankshaft Repair Machine Service | RA Power Solutions

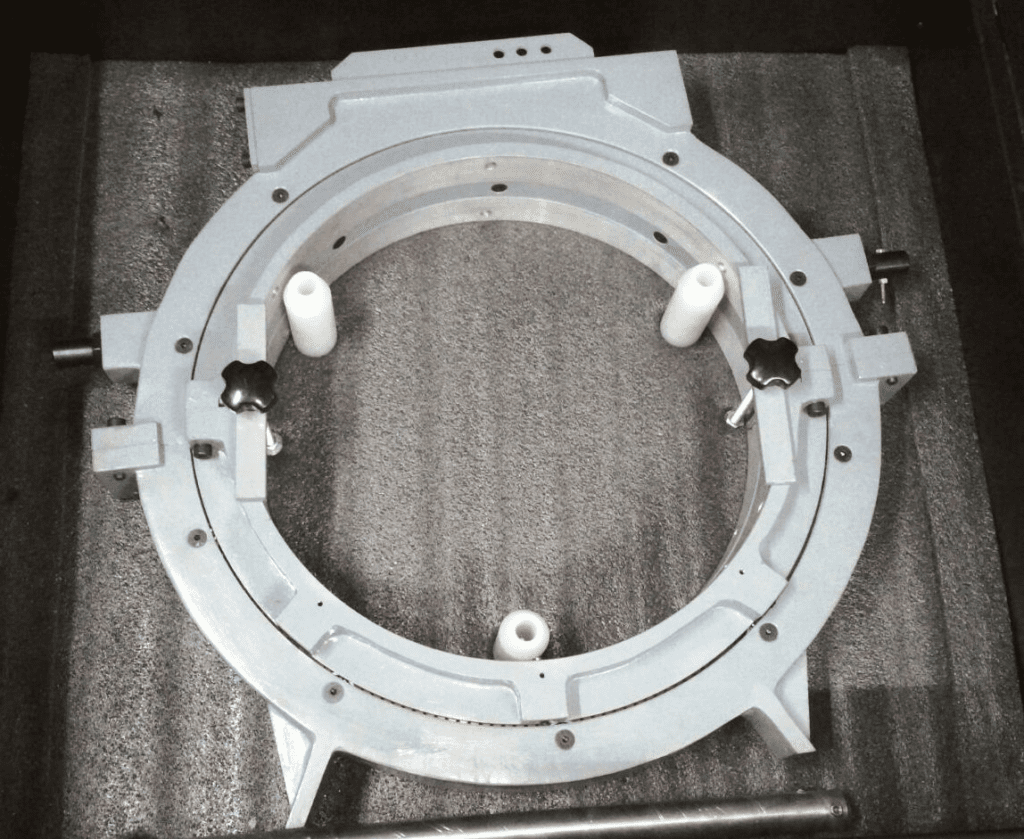

RA Power Solutions manufactures a crankshaft repair machine, which is the latest solution for the repair of damaged crankpins and the main journal of the crankshaft onsite. The crankshaft repair machine is available in the range from 60 mm to 700 mm, which caters to almost all the capacities of engines installed on board a vessel in power plants and other applications.

The crankshaft repair machine has the following features:

I) We developed the crankshaft repair machine (crankshaft grinding/crankshaft polishing machine) from our experience. We refined it through extensive field applications and research.

II) A Lightweight, portable crankshaft repair machine can be carried to any site all over the world.

III) The crankshaft repair machine is compact. You place it on the crank pin through the crankcase inspection window for grinding and polishing. There is no requirement for the dismantling of the crankshaft from the engine block.

IV) The crankshaft repair machine is of the latest design, which results in almost no vibration.The machine controls taper and ovality within 0.02 mm. It also follows the requirements of the engine manufacturer.

V) The crankshaft grinding and polishing machine is easy to operate and understand. Training is an integrated package of this product.

VI) The machine is recommended and has proved its worth in different applications like land-based engines, process industry, shipping, etc.

VII) Cost-effective and perhaps this is the first revolutionary crankshaft grinding equipment that is affordable for repair workshops, shipping companies, Power plants, and the repair industry.

RA Power Solutions: Global Service

RA Power Solutions offers top-notch crankshaft machining services and crankshaft repair tools for all types of crankshafts. With their cutting-edge technology and skilled technicians, they can efficiently handle any crankshaft repair or machining requirements.

Whether it’s a marine, industrial, or power generation application, RA Power Solutions ensures precision and quality in its work. Their specialized crankshaft repair tools and equipment tackle complex repairs. They restore crankshafts to their original specifications. When it comes to crankshaft solutions, RA Power Solutions is the go-to choice for reliable and cost-effective services.

We have supplied more than 1000 crankshaft repair (crankshaft grinding and crankshaft polishing machines) all over the world.

For more information on crankshaft machining service on and crankshaft repair equipment, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

Yes. It is lightweight and portable, designed for field applications. It is especially useful for vessels, power plants, shipping, and similar settings.

The product includes training. The machine offers easy operation. RA Power Solutions provides support to ensure operators use it effectively.

The machine supports crankpins and main journals from 60 mm up to 700 mm bore size, covering most engine capacities in marine, power plants, and industrial applications.

Yes, the repair/polishing machine is portable and compact, and can be placed through the crankcase inspection window. This allows grinding and polishing without removing the crankshaft.

The device maintains tight tolerances. It controls taper and ovality within ~0.02 mm or follows the engine manufacturer’s specification.