Crankshaft Grinding And Repair of High Capacity Engine

Crankshafts are the heart of large diesel engines, whether in marine vessels, power plants, or heavy industrial machinery, and their performance directly affects overall engine reliability and life. High-capacity engine crankshafts can be extremely large, sometimes 6–12 meters long and weighing up to 20 tons, with crankpins and main journals ranging from 500 mm to over 700 mm in diameter. When wear, deformation, or surface damage occurs, on-site crankshaft grinding and repair become essential to restore performance without costly downtime.

Why On-Site Crankshaft Repair is Recommended

- Irrespective of whether diesel engines operate in marine or land-based applications, they run continuously in most cases, which results in various deviations in the crankshaft.

- Technicians need to check the measurements of various parameters, including taper and ovality, periodically or during overhauling and maintain them within the stipulated tolerances.

- The parallelism, linearity, and run-out have to be within limits.

- The surface finish of the crankpin and main journal have to be within The surface finish of the crankpin and the main journal have to be within the standards.

- The radius fillet and lubricating oil hole should be according to the original profile and dimensions as per the drawing of the crankshaft.

Above are some of the reasons that require crankshaft grinding and crankshaft repair.

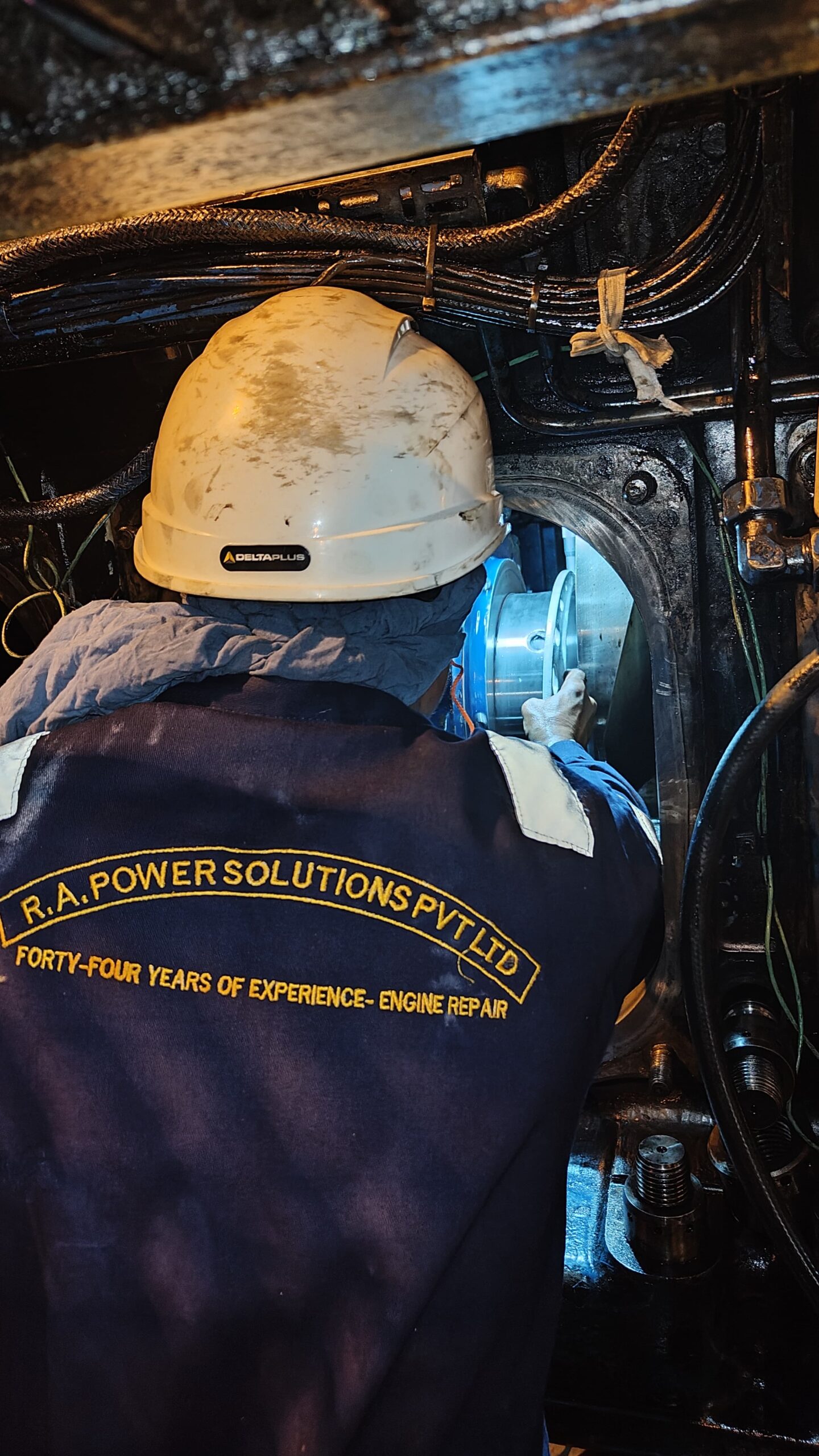

RA Power Solutions Pvt. Ltd. with experience of more than four decades, undertakes crankshaft grinding and crankshaft repair up to the diameter of 700 mm on-site and without removal of the crankshaft from the engine block. The length and the weight of the crankshaft are not a criterion for us for Crankshaft grinding or Crankshaft repair.

The following parameters are maintained at the time of crankshaft grinding and crankshaft repair

- The Taper and ovality of the crankpin and main journal are strictly maintained as per the tolerances stipulated in the manufacturer’s manual.

- After RA Power Solutions undertakes grinding and repair, the team maintains and checks all parameters, such as surface finish, radius fillet profile, lubricating oil holes, and parallelism, according to the original specifications.

- Experienced technicians inspect the crankshaft for all parameters and prepare inspection reports, which they share with the clients.

.

RA Power Solutions gives great importance during crankshaft grinding and crankshaft repair not only to maintaining taper and ovality but also to achieving the surface finish of the crankpin and main journal within an Ra value of 0.3 µm.

Why Choose Professional On-Site Repair Services

Companies specializing in on-site crankshaft grinding and repair bring:

- Decades of experience with precision field machining

- Portable grinding equipment for large diameter crankshafts

- Skilled technicians trained in inspection and dimensional validation

This approach ensures crankshafts operate more smoothly, last longer, and deliver higher reliability—without the cost and complexity of removal and workshop rework.

For your requirement of onsite crankshaft grinding, on-site machining services, in situ crankshaft grinding repair, crankshaft grinding and repair, marine crankshaft repair, you may email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Check Out Our Latest YouTube Video here: https://youtu.be/uxMGFe8RWkc

FAQs:

Onsite crankshaft repair restores worn or damaged crankpin and main journal surfaces using portable grinding machines without removing the crankshaft from the engine block.

Grinding corrects wear, taper, ovality, and surface damage, restoring the crankshaft to manufacturer-specified tolerances for smooth operation.

Yes, modern portable machines can handle crankshafts with journal diameters of up to 700 mm, regardless of their overall length or weight.

Marine, power generation, industrial engines, compressors, and heavy machinery sectors benefit from this service.

It eliminates the need for removal, transportation, and workshop rework, which significantly reduces downtime and overall cost.