Babbitt White Metal Bearing | Turbine Bearing Repair of 120 MW

Turbine Journal Bearing Manufacturer

RA Power Solutions undertakes Rebabbitting of Babbitt white metal bearings for last more than 45 years of thrust, crankpin, and main journal, turbine, rotor, and alternator bearings for all applications up to 1500 mm diameter.

At RA Power Solutions, we take pride in our expertise as a turbine journal bearing manufacturer and our ability to provide exceptional repair services for Babbitt white metal bearings.

In this blog post, we highlight our recent accomplishment in Nigeria, where we successfully repaired a 120 MW turbine bearing. Our team of highly skilled technicians and advanced facilities enabled us to overcome the challenges and restore the bearing’s functionality efficiently.

Read on to learn more about our expertise as a turbine journal bearing manufacturers, turbine bearing repair of 120 MW, and how we handled this complex repair project.

OUR EXPERIENCE IN REBABBITTING OF WHITE METAL BEARING:-

- Extending the services of Rebabbitting and repair of white metal bearings all over the world for more than 45 years.

- We strictly perform the rebabbitting of Babbitt white metal bearings up to 1500 mm using the centrifugal process, ensuring a strong bond between the Babbitt white metal and the steel base of the bearing.

- In-house machining facilities with an accuracy of 10-20 microns are achieved.

- Regularly undertaking Rebabbitting assignments of prestigious organizations from the field of nuclear power stations, high-capacity turbines and generators, and main and auxiliary engines.

- Facilities for metallurgical analysis of Babbitt white metal and expert recommendation for enhancing the quality of Babbitt white metal for an increase in service life.

- All bearings are subject to strict quality control norms by experienced technicians for hardness tests, crack checks by MPI, dimensional checks, and ultrasound for bonding.

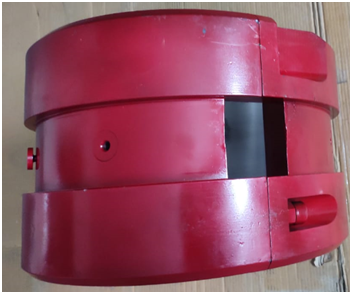

REPAIR OF 120 MW TURBINE BEARING UNDERTAKEN FOR A LEADING NIGERIAN STEEL COMPANY:-

A leading steel company based in Nigeria approached us to rebabbitt a white metal turbine bearing with a capacity of 120 MW. They had previously relied on a European company for the repairs, but those bearings failed after a short period, delivered unsatisfactory performance, and came at an exorbitant cost.

RA Power Solutions undertook the successful repair of rebabbitting of the 120 MW turbine bearing.

THE DETAILED MAIN DIMENSIONS OF THE TURBINE BEARING ARE MENTIONED BELOW:

| S. NO | Dimensions of Turbine Bearing | |

| 1 | Nominal Bore | 315 mm |

| 2 | Width of Bearing | 257 mm |

| 3 | OD of Bearing | 445 mm |

| 4 | Height of bearing | 260 mm |

| 5 | Finishing bore diameter | 315.42+0.02-0.00mm |

| 6 | Weight | 150 kg |

Upon receiving the bearing from Nigeria, we thoroughly inspected it for the following:

- We removed the old white Babbitt metal under controlled temperature conditions.

- We performed shot blasting on the bearing shell.

- We checked the hardness of the inner diameter.

- We performed crack detection on the bearing steel casing using MPI and dye-penetration tests.

- We conducted crack detection tests using the ultrasound method both before and after rebabbitting.

- We conducted ultrasound testing again to check the bonding between the Babbitt white metal and the steel casing.

- Assistance was provided in the transportation of heavy bearings to our works for white metal rebabbitting from other countries.

- We provide complete assistance in the export of damaged bearings and return of bearings to the end-user after turbine bearing repair.

- We have a definite advantage of our location as we are only 30 30-minute drive from New Delhi International Airport.

- Our plant is also close to the dry port of New Delhi, in case our client wants to dispatch the bearing by sea.

We provided emergency services for the repair of the white metal bearing.

1. Emergency Repair Services

We provided emergency services for the repair of the white metal bearing.

2. 24/7 White Metal Rebabbitting Services

Our team provides 24/7 white metal rebabbitting services and ensures the fastest possible delivery.

3. Competitive and Reasonable Pricing

Clients recognize us for our reasonable pricing.

4. Proven Expertise in Turbine Bearing Repair

As a trusted turbine journal bearing manufacturer, we successfully repaired a 120 MW turbine bearing in Nigeria, demonstrating our commitment to reliable and efficient solutions for complex bearing repair projects.

5. Commitment to Quality and Technology

With extensive expertise, cutting-edge technology, and unwavering dedication to quality, we consistently support the power generation industry by delivering exceptional repair services for Babbitt white metal bearings.

6. Global Clientele and Experience

We have been regularly undertaking rebabbitting of white metal bearings for reputed steel, fertilizer, and shipping companies based in countries like Austria, Belgium, Denmark, Finland, France, Germany, Greece, Ireland, Italy, Luxembourg, Netherlands, Portugal, Spain, Sweden, United Kingdom, Nigeria, Sri Lanka, and more.

For more information on babbitt bearing and turbine journal bearing manufacturers, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs

RA Power Solutions performed rebabbitting and refurbishment of the turbine’s white‑metal journal and thrust bearings using their centrifugal casting process.

They manufacture and rebabbitt Babbitt white‑metal bearings for industrial equipment up to 1500 mm bore diameter.

Old Babbitt metal is removed, the steel casing is shot‑blasted and tested for cracks and hardness (MPI/dye‐penetrant), then a new, higher‑grade Babbitt white‑metal is fitted by centrifugal casting, followed by CNC machining and ultrasonic bonding inspection.

Yes—they offer reverse engineering: technicians measure worn bearings on-site, develop CAD‑CAM drawings, and then manufacture new bearings to exact client specifications .

They use multiple quality‑control steps:

Magnetic particle inspection (MPI) and dye‑penetrant tests after removal of old metal,

Hardness testing and scooping of hard spots,

Ultrasonic testing post‑casting to verify bonding,

Final CNC machining per tight tolerances,

And full inspection and reporting before shipping.