Babbitt White Metal Bearing Manufacturing and Repair

RA Power Solutions stands as a trusted leader in the design, development, manufacturing, and repair of white metal Babbitt bearings, supporting industries ranging from marine and alternators to diesel engines and turbines.

Different Grades of Babbitt White Metal for the Manufacturing of Bearings

Depending on the application of the bearing, load characteristics, the environment in which the bearing is in operation, the type of lubricating oil used, RPM of the shaft, etc the grade of bearing is selected. We also use the Babbitt white metal grade as recommended by the manufacturer of the equipment or use the Babbitt white metal based on our experience. In any case, the BEZ alternator Babbitt white metal bearing used by us is of better quality than what was originally used.

The use of European quality and higher grade of Babbitt white metal results in a considerable increase in the life of Babbitt white metal bearings manufactured by us. It is proven that the high quality of Babbitt white metal bearing also increases the life of the shaft on which it is assembled. The crankshaft, rotor shaft, pump shaft, turbine shaft, cylinder shaft, and shafts of all applications life increase manifolds.

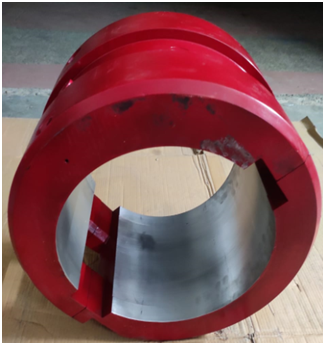

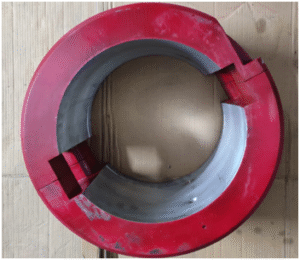

Manufacturing of an Alternator and an Engine Bearing

We manufacture crankpin and main journal bearings for diesel engines. We are the largest manufacturers and exporters of CKD Skoda engines and SKL engine alternators, crankpins, and main journal bearings.

Repair and Rebabbitting of Old Bearings

We have the facilities for repairing and rebabbitting of old bearings in a minimum duration of time.We follow the same process for rebabbitting white metal as we do for manufacturing new bearings. We carefully select and use only high-quality white metal for rebabbitting old and damaged bearings.

The following quality control tests are undertaken before the dispatch of bearings from our works.

- Checking the hardness of the bearing shell.

- Crack detection by MPI.

- Metallurgical analysis of white metal.

- An ultrasound test of Babbitt white metal bonding with steel lining.

- Dimensional inspection.

Global Reach & OEM-Level Reliability

With over four decades of experience, we export our bearings and repair services worldwide—across industries and continents. Our deep expertise ensures we meet OEM standards and deliver cost-effective, long-lasting solutions.

Get in Touch:

For more information regarding BEZ alternator babbitt white metal bearing, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

We manufacture and repair Babbitt bearings with bore sizes ranging from 50 mm to 1500 mm.

We use the centrifugal casting process in a controlled temperature environment, ensuring strong bonding between the Babbitt metal and the steel shell.

Yes, we specialize in rebabbitting and repairing worn-out bearings, restoring them to OEM specifications or better.

Our inspections include MPI crack detection, ultrasonic bond testing, hardness checks, and CNC dimensional verification to guarantee reliability.

We offer fast turnaround services, and in urgent cases, we can complete rebabbitting and supply bearings within 24 hours.