Babbitt Bearing | White Metal Babbitt Bearing | Bearing Manufacturer

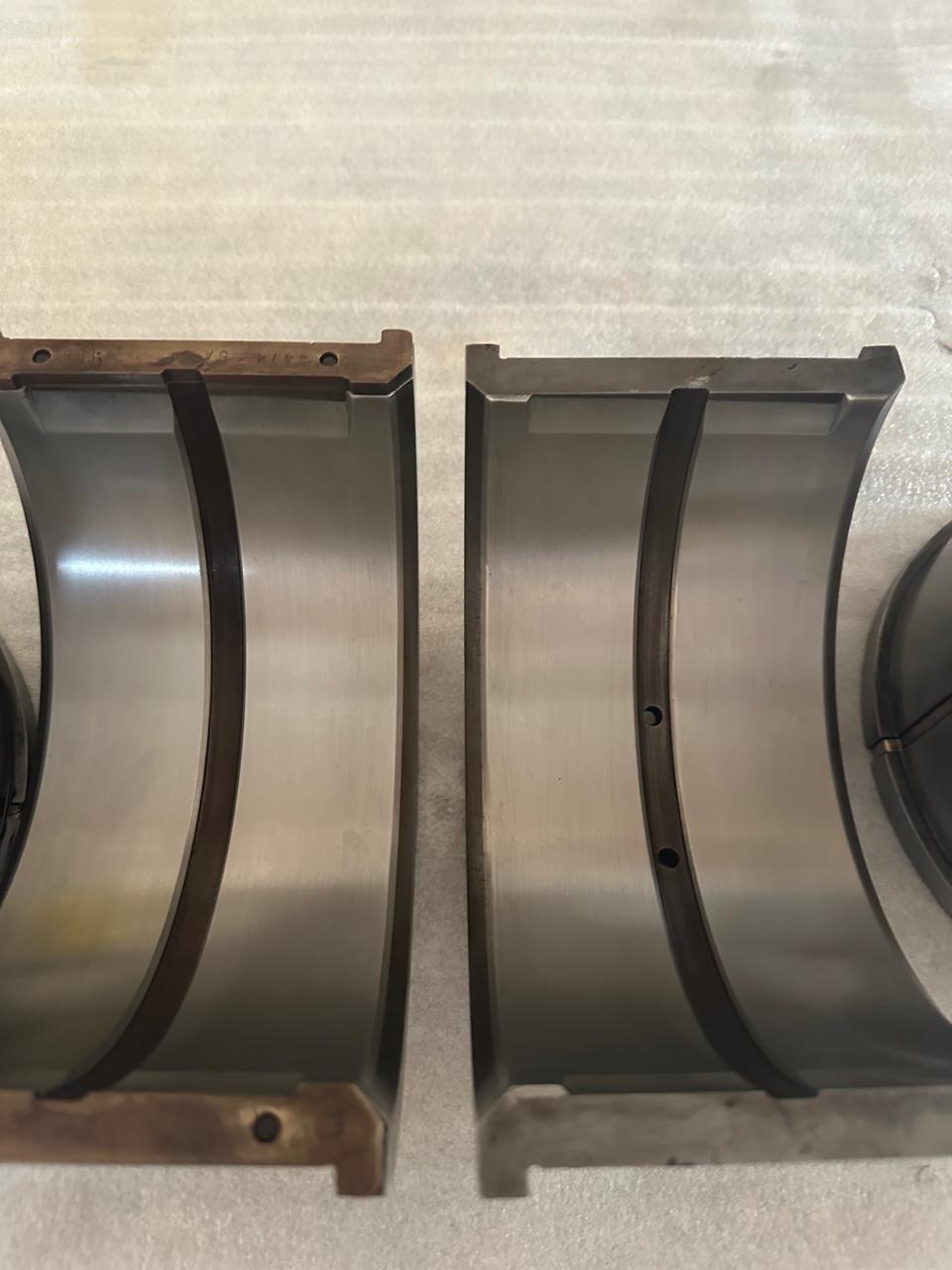

RA Power Solutions manufactures new white metal babbitt bearings as per the drawing or sample. We also undertake repair and rebabbitting of old white metal babbitt bearings, which get worn out or damaged due to an accident.

Rebabbitting Bearings with Centrifugal Casting

The rebabbitting of old bearings and babbitting of new bearings by the centrifugal casting process is the most popular. It results in high-quality bonding between the babbitt white metal and steel lining of the bearing. In this process, we spin babbitt metal to the bearing housing (outer steel lining of the bearing) in spin fixtures. Variable-speed drive units actuate the process and ensure proper alloying and bonding of white metal with the steel shell. We strictly control the temperature of the white metal and the bearing shell.

Static Pouring Process:

We commonly use the process of static pouring of babbitt white metal. We follow this method when the centrifugal process is not possible due to design restrictions or the profile of the white metal bearing.

Pour each bearing with a continuous pour of white metal, eliminating the possibility of cracks or joints in the babbitt. This also avoids any possibility of premature failure of bearings.

Rough Machining and Final Machining of Bearings

We have an in-house facility for rough machining and final machining of bearings after babbitting the white metal. We machine the inner diameter and other critical dimensions on CNC machines fitted with DRDO devices.

This ensures that the white metal babbitt bearing, after manufacturing or rebabbitting, has all dimensions exactly as per the drawing and specified tolerances. As a repair company, we understand the importance of maintaining critical dimensions.

We are an ISO 9001:2015 certified company and follow strict quality control, which includes the following:

- MPI for crack detection of bearing shell before white metal babbitting process. A Level II qualified technician performs this work. The technician conducts the MPI test for crack detection before and after the shot blasting process.

- We do not accept any cracks in the bearing steel shell. If we observe a crack, we either reject the bearing shell or, in consultation with our senior engineers, remove the cracked area by the scooping process. We check the bonding of white metal with the steel shell by ultrasound. We do not accept any abnormality.

- We thoroughly check dimensional accuracy for taper, ovality, and all other critical dimensions important for assembly.

- 24×7 repair services for rebabbitting.

We understand the urgency of white metal babbitt bearings, especially when clients send them to us for repair.

The import and export of white metal babbitt bearings after repairs are organized by the logistics team.

White metal Babbitt bearings are supplied all over the world, including countries like Singapore, Malaysia, Colombia, Indonesia, Hong Kong, Spain, Netherlands, Dubai, Portugal, Estonia, Morocco, Belgium, Vietnam, and Canada.

For your requirement of new white metal babbitt bearings, bearings for Daihatsu engine, and old bearing repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or+91 9810012383.

FAQs:

Rebabbitting restores worn bearings by replacing the old Babbitt lining with new white metal.

We offer quick turnaround, with emergency repairs possible within 24 hours.

We conduct MPI crack testing, ultrasonic bonding checks, and dimensional inspections.

Yes, we manufacture new bearings up to 1500 mm in diameter as per drawings or samples.

We serve marine, power plants, steel, cement, mining, and many other industries worldwide.