Onsite Crankshaft Grinding Machine | Crankshaft Grinding And Repair

At RA Power Solutions, we understand how critical crankshaft condition is to the performance and longevity of marine engines, diesel sets, turbines, compressors, and other heavy rotating equipment. That’s why for over four decades, we’ve been pioneering onsite crankshaft grinding and repair, using advanced, portable grinding machines designed to restore crankpins, main journals, and polished surfaces with precision.

What Is Onsite Crankshaft Grinding?

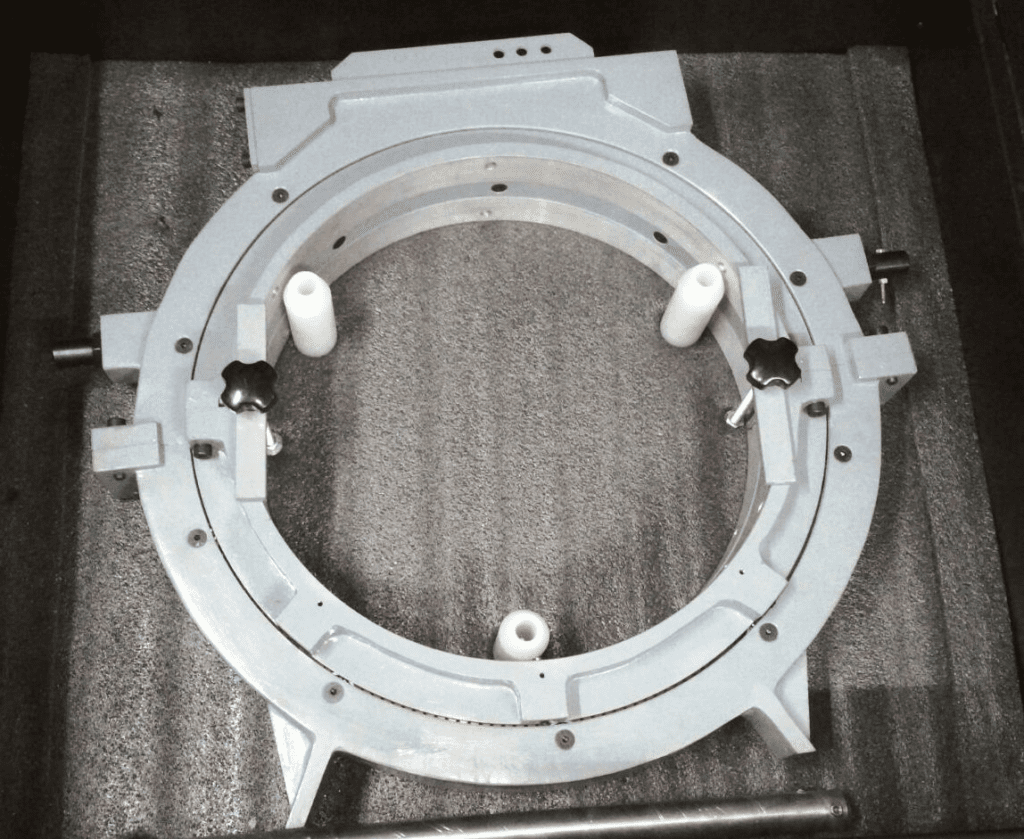

The on site crankshaft grinding machine is manufactured having a range starting from 30 mm to 700 mm in terms of diameter. The smaller diameter of the on site crankshaft grinding machine up to 100 mm is more suitable for grinding and polishing crankshafts used in construction equipment, compressors, pumps, etc.

The crankshaft grinding machine having a range of 100 mm and above is ideal for undertaking crankshaft repair, crankpin grinding, and polishing of marine engines and heavy-duty rotating equipment.

We are the leading provider of onsite crankshaft grinding machines and polishing, Insitu turbine shaft Grinding and Polishing, Rotor Shaft Grinding and Polishing, Portable crankshaft grinding machines, crankshaft grinding and repair.

Key Features of Our Crankshaft Grinding Machines

- Wide diameter range — capable of handling from small shafts (≈ 30-100 mm) used in pumps, compressors, etc., up to heavy crankshafts in marine engines.

- Portable / in-situ design — smaller footprint, easier setup, reduced downtime.

- Durable materials — main structural parts built from titanium / ferrous alloys to handle stress and maintain precision.

- Operator training & support — includes on-site training so technicians can operate and maintain the machine safely and effectively.

Benefits of Choosing On-Site Grinding

| Traditional (bench) grinding | OnSite / Portable Grinding |

| Requires dismantling, transportation | Machine comes to the site, minimal movement |

| High cost and long downtime | Reduced repair time & costs |

| Risk of damage during handling | Less handling; safer for crankshaft |

| Less flexibility for large shafts | Suitable for large & marine-scale jobs |

Clients have also noted that with onsite crankshaft grinding, the repair turnaround is much faster, leading to less downtime and lower overall cost.

Why RA Power Solutions?

With 45 years of experience, RA Power Solutions has recently supplied a crankshaft grinding machine, ranging in diameter from 220 to 260 mm, to a Bangladesh-based client. This is the first onsite crankshaft grinding machine to be sold in Bangladesh. Several diesel-generating sets are in operation, serving a large population of vessels that pass through the various ports of Bangladesh.

At RA Power Solutions, we prioritize customer satisfaction and strive to deliver top-quality services that exceed your expectations. Our on site crankshaft grinding machine is just one example of our commitment to providing innovative solutions for engine repair and maintenance.

For more information regarding crankshaft grinders, crankshaft grinding services, and crankshaft grinding equipment, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

No,our portable insitu machines allow grinding/repair without shaft removal.

Roughly one week to operate and maintain the machine properly.

It cuts down dismantling, transportation, engine downtime, and handling risks.