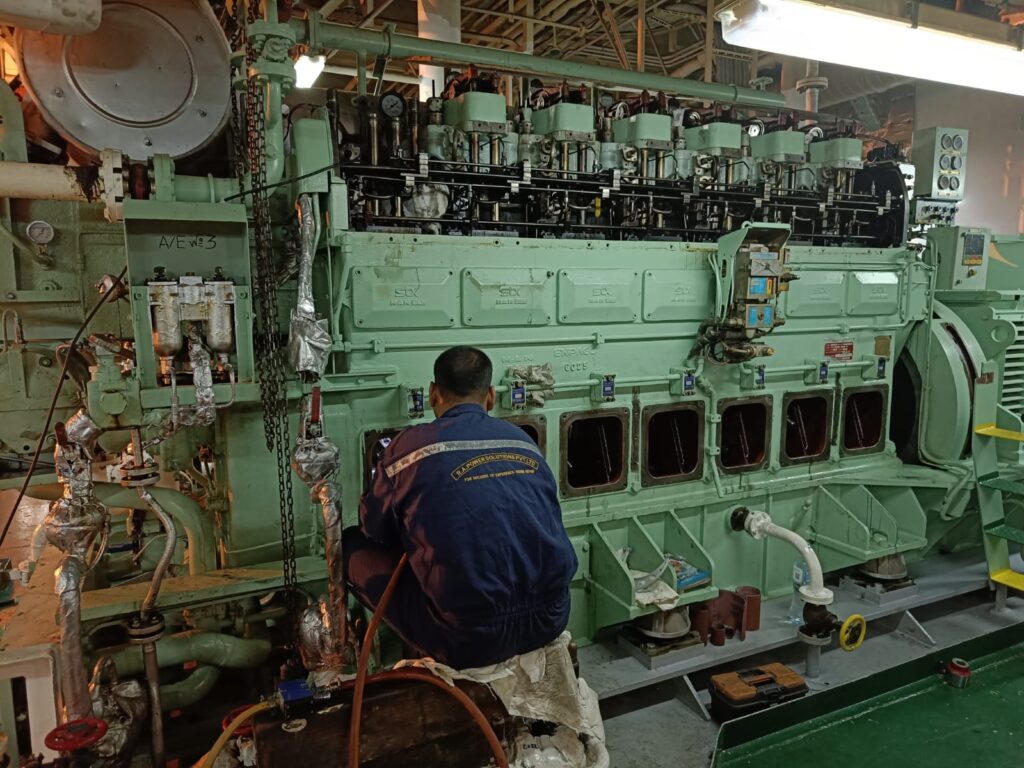

Onsite Crankshaft Repair – RA Power Solutions

Crankshaft Repair is important for engines running continuously. It is observed that the crankshaft, crankpin, and main journal develop taper and ovality after certain hours of operation. This needs crankshaft repair.

At RA Power Solutions, we offer advanced crankshaft repair services that restore crankshafts to original specifications with minimal downtime and maximum reliability. Our skilled engineers use portable, lightweight on-site crankshaft grinding and polishing machines that eliminate the need to remove the crankshaft from the engine, saving time, cost, and operational disruption.

Why Crankshaft Repair Matters

Over time, bearings wear and crankshaft journals develop rough surfaces and out-of-round conditions. These issues, if ignored, can result in:

- Increased engine vibration

- Reduced oil film formation

- Higher fuel consumption

- Costly breakdowns

With professional crankshaft repair, these problems are corrected before they lead to major failures. The crankshaft is ground and polished back to precise tolerances, restoring smooth surfaces and optimal engine performance.

Global Expertise & Reliable Execution

RA Power Solutions Pvt. Ltd. has associated with leading shipping companies and diesel power plants and has undertaken crankshaft repair and onboard crankshaft repair for more than 45 years. The company has successfully executed the repair of more than 10,000 crankshafts.

For more information on Onsite Crankshaft Repair, Crankshaft Repair Service, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

Crankshaft repair service restores worn or damaged crankshafts by grinding and polishing journals back to precise OEM specifications.

On-site grinding eliminates the need to remove the crankshaft, cutting downtime, labor, and transport costs significantly.

Portable grinding machines can handle crankshaft journal diameters from 35 mm up to 700 mm.

Yes, restoring smooth, precise journal surfaces reduces friction, enhances oil film formation, and improves efficiency.

On-site repairs are faster than traditional methods, often completed in a fraction of the time with minimal engine downtime.