In Situ Grinding Crankpins | Insitu Crankshaft Grinding Services

In Situ Grinding Crankpins | Insitu Crankshaft Grinding Services

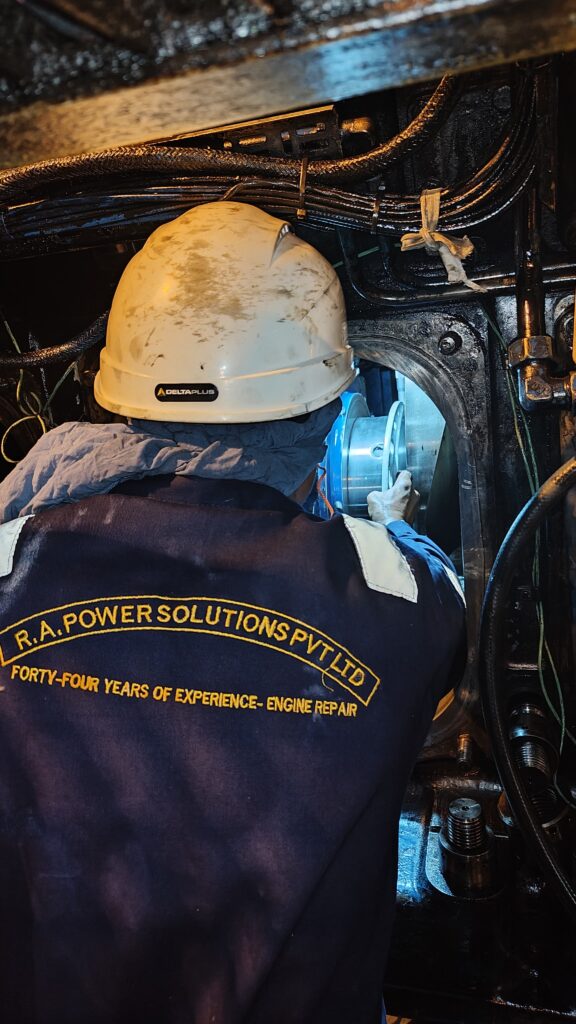

With over four decades of experience, RA Power Solutions provides in situ crankshaft grinding, crankpin grinding, crankshaft inspection, and repair services for large, high-capacity marine engines and engines used in various industrial applications.

In olden times, whenever the crankpin or main journal of the crankshaft was damaged due to bearing failure or any other reason, the crankshaft was removed from the engine block by disassembly of the complete engine, packed, and taken to the workshop for grinding on a stationary crankshaft grinding machine.

Introduction of On Site Machining Tools:

With the introduction of an onsite machining tool, it is possible to undertake the repair of the crankpin and main journal. RA Power Solutions undertakes onsite grinding of crankshaft and main journal of the diameter ranging from 35 mm to 700 mm. The repair is possible without disassembling the engine, and there is no need for the removal of the crankshaft. The portable and lightweight crankshaft machining tool is inserted from the window for grinding and polishing.

Why This Technology Stands Out

| Advantage | What It Means for You |

| Worldwide, mobile deployment | Technicians carry the machine to any site for fast response |

| Cost savings on downtime | Repairs avoid engine disassembly, minimizing downtime and expenses |

| Precision and quality | Maintains dimensional tolerances within 10–25 microns, with OEM-level surface finish |

| Lower freight costs | Machine weighs only one-third of competitors, reducing shipping costs |

| Lower freight costs | RA Power provides training on operation and upkeep, empowering your team |

The following are the advantages of using RA Power Solutions’ in situ grinding crankpins services:

- Experienced technicians to assess the fault in the crankshaft and plan the repairs.

- The latest design of portable crankshaft grinding tools ranges from 35 to 700 mm.

- The lightweight machine can travel as accompanied baggage by air to any part of the world.

- Our crankshaft grinding machine weighs 1/3rd of our competitors saving on freight costs.

- RA Power Solutions is the world’s largest manufacturer of portable in situ crankshaft grinding. machines having sold more than 80 crankshaft grinding machines all over the world. Technicians can modify and manufacture the dedicated machine according to the space available at the site.

- Minimum repair time and cost of downtime are reduced considerably.

- A company having more than forty- five years of experience.

- The latest breed of inspection instruments is available to undertake hardness tests, MPI, surface roughness tests, dimensional inspection, etc.

- We are a New Delhi-based company and offer rates that are considerably lower than European companies.

Real-World Success: Grinding Underway at Sea

RA Power Solutions accomplished a remarkable offshore repair on a MAN B&W 6L 28/32H crankshaft during a vessel’s voyage from Cape Town to India. Their technicians:

- Measured each crankpin’s taper, ovality, and hardness.

- Used MPI to inspect for cracks (none found).

- Re-grinded all crankpins by 0.5 mm (from 230 mm to 229.50 mm).

- Delivered tolerance results within 0.03 mm accuracy—all while the ship was sailing.

For more information on in situ crankshaft grinding and in situ crankshaft grinding repair, please email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

Onsite crankshaft grinding repairs crankpins and main journals without removing the crankshaft.

They grind crankshafts and main journals from 35 mm to 700 mm in diameter.

No, the repair process works without disassembling the engine.

The machine is centerless and uses the same principle as bench-type crankshaft grinders.

It avoids referencing the crankpin’s fillet, preventing damage during grinding.