Rebabbitting of Old Turbine Bearing | Repair of Turbine Bearing | Babbitt White Metal Bearing Manufacturing Company

RA Power Solutions was approached by a steel manufacturing company located in the western part of India for the problem faced by them in turbine bearings. Technicians equipped with the necessary instruments visited the site and inspected the damaged white metal turbine bearings and turbine shaft.

Following are the main observations:-

Turbine bearing inspection

- The turbine bearing was removed from the shaft, and it was observed that the white metal from the bearing was partially removed.

- Heat exposed a portion of the turbine bearing, turning it a blackish colour.

- Deep bearing line marks appeared on the rest of the bearing’s inner diameter.

Observations on turbine shaft:-

- We calibrated the turbine shaft and observed that the dimensions, taper, and ovality were within the limits specified in the manufacturer’s manual.

- We noticed line marks on the turbine shaft bearing sitting area.

- We checked the surface finish of the turbine shaft and bearing sitting area and found it rough.

Action taken by RA Power Solutions to put the plant back into operation in minimum possible time:-

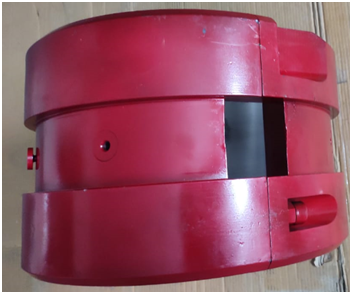

- We received the turbine bearing in our workshop for inspection and rebabbitting.

- Our team thoroughly inspected it for hardness and cracks using the MPI method before starting the rebabbitting process.

- We polished the turbine shaft bearing seating area with the latest generation onsite polishing machines.

- We removed the bearing line marks and maintained the surface finish of the turbine shaft’s bearing seating area at less than 20 RA value.

- After the final machining of the white metal babbitt turbine bearing inner diameter, the bearing was dispatched and assembled at the site.

- The turbine was put back into operation in the minimum possible time.

The broad details of turbine bearings are as following:-

| S. No. | Descriptions | Dimensions Observed |

| 1 | Bearing Inner Diameter | 430 mm |

| 2 | Bearing Outer Diameter | 690 mm |

| 3 | Bearing Total Width | 360 mm |

Customization of white metal Babbitt bearing

We have a strong technical team that can develop and manufacture white metal babbitt bearings based on the drawing or sample. We have the expertise in developing bearings by reverse engineering, and we have successfully developed hundreds of bearings after manufacturers discontinued their production.

QUALITY OF WHITE METAL BABBITT BEARINGS

Right from the process of Rebabbitting to the selection of raw material, inspection at different stages of repair of old bearings, and manufacturing of new bearings, results in a high-quality product for which we are known all over the world. We have a very strong client based in South America, UAE, and other countries.

Cost of white metal babbitt bearings and low cost of repair

It is our sincere endeavor to continuously reduce the cost of manufacturing new white metal Babbitt bearings or to undertake the repair of bearings. Moreover, this is possible because we utilize our in-house facilities to the optimum level.

Service

We carry out the repair and maintenance of new bearings with complete sincerity and guarantee customer satisfaction.

We stand guarantee for the satisfactory performance of bearings.

For more information regarding repair and rebabbitting of old bearings, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs

Rebabbitting is the process of removing worn or damaged Babbitt white metal from a bearing shell and recasting a new layer—typically using centrifugal casting—in order to restore the bearing’s original fit, performance, and lifespan. Consequently, industries widely use this cost-effective repair method for turbine, rotor, and alternator bearings up to 1500 mm in diameter.

The process starts with removing old white metal under controlled temperature. Then, the steel casing is shot-blasted. Next, technicians test hardness and eliminate hard spots. After that, they inspect for cracks using MPI, dye-penetrant, or ultrasonic testing. Centrifugal casting of high-grade Babbitt follows. Subsequently, CNC machines cut to precise tolerances. Finally, ultrasonic testing and dimensional reporting verify quality.

They can manufacture and rebabbitt white metal bearings up to 1500 mm in bore diameter, covering applications such as turbine, alternator, pump, engine, rotor, crankshaft, and thrust pad bearings.

They use centrifugal casting to achieve strong, uniform bonding. After casting, we verify bond integrity using ultrasonic testing and dye-penetrant inspection, ensuring the new metal securely adheres to the base.

Yes. RA Power Solutions provides in-situ services for shaft repairs—such as crankshaft and turbine shaft grinding and polishing—without requiring full disassembly of equipment. As a result, this significantly reduces downtime and, moreover, ensures seamless integration with the rebabbitting process.