Turbine White Metal Bearing – RA Power Solutions

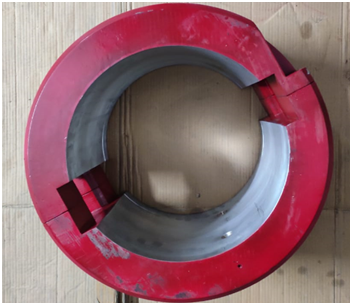

Turbine white metal bearings are required for industrial turbines to operate smoothly and reliably. These bearings, which are designed to sustain high radial and axial loads, reduce friction between rotating components and their housings, resulting in efficient operation and a long service life.

At RA Power Solutions, we specialise in the manufacturing of new white metal bearings as well as expert rebabbitting and repair services for bearings that have worn out during operation.

What Are Turbine White Metal Bearings?

White metal bearings, also known as Babbitt bearings, are manufactured out of a soft alloy lining (usually tin, antimony, or copper) that is bonded to a steel backing. This combination results in an excellent surface that decreases friction while resisting wear at high loads and speeds.

These bearings sustain the rotating shaft in turbine applications while reducing heat generation and vibration, making them critical components in power plants and heavy equipment.

The base metal on which the babbitting of the white metal bearing is carry out must be free from cracks and hard spots. To achieve strong bonding between the Babbitt white metal and the base lining, manufacturers prefer the centrifugal casting process. This process ensures a uniform layer of Babbitt white metal with a dense and consistent microstructure.

Advantages of Turbine White Metal Bearings

Industrial white metal bearings offer several key benefits:

- Low friction and wear resistance, ensuring smooth shaft rotation.

- Shock and vibration absorption increases durability in heavy machinery.

- High load capacity and reliability, ideal for turbines, generators, and large engines.

- Custom manufacturing & repair, tailored to specific shaft sizes up to 1500 mm.

- Reduced operating costs, rebabbitting old bearings saves money over replacement.

Why Choose RA Power Solutions?

RA Power Solutions Pvt. Ltd. manufactures new white metal Babbitt bearings and carries out rebabbitting of white metal bearings damaged during operation. The company manufactures the bearings according to the turbine shaft sizes obtained after grinding and polishing.

For more information on Turbine white metal bearings, white metal bearings, Crankshaft Grinding Services, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

A turbine white metal bearing is a Babbitt-lined plain bearing that supports turbine shafts, reducing friction and wear under heavy load conditions.

They reduce friction, dissipate heat efficiently, absorb shocks, and help maintain smooth rotational movement for turbines and other heavy machinery.

Rebabbitting involves removing worn white metal and re-casting new Babbitt alloy onto the bearing shell, followed by precision machining and quality checks.

The bearing alloy typically includes tin, antimony, and copper, balancing low friction with strength and corrosion resistance.

Yes, bearings can be custom-made as per client requirements and shaft size, up to 1500 mm diameter.