What Is Rebabbitting of a Bearing?

Rebabbitting of bearing is the process of removing worn Babbitt metal from a bearing shell and applying a fresh layer to restore its original performance. This is essential when the Babbitt surface shows wear, damage, or degradation that affects bearing reliability.

Why Rebabbitting Is Important

Rebabbitting brings a damaged or worn bearing back to OEM-level efficiency by restoring:

- Correct bearing geometry

- Load-carrying capacity

- Lubrication flow

- Vibration and heat control

Signs Your Bearing Needs Rebabbitting

If you notice any of these issues, the bearing likely needs immediate inspection or rebabbitting:

- Wear marks or uneven surfaces

- Scoring, pitting, or blistering

- Burn marks or discoloration

- Lubrication breakdown

- Excess vibration or noise

These symptoms often indicate deeper problems in the shaft line or lubrication system, so early diagnosis is crucial.

How Rebabbitting Is Done

Inspection & Non-Destructive Testing

Technicians inspect the bearing for cracks, alignment issues, and material fatigue.

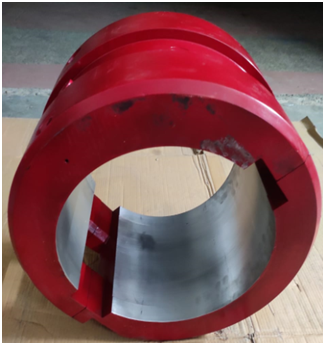

- Old Babbitt Removal

They melt or machine off the worn Babbitt layer from the shell. - Surface Preparation

They clean, tin, and prep the shell to ensure a strong bond. - New Babbitt Casting

High-grade babbitt metal—typically tin-based—is poured or centrifugally cast. - Machining to OEM Specs

They bore, chamfer, and finish the new Babbitt surface to precise OEM tolerances. - Final QA & Clearance Check

The bearing is tested for geometry, hardness, bond strength, and fit.

Why Babbitt Metal Is Used

Babbitt works as a soft, protective layer that:

- Embeds contaminants (protecting the shaft)

- Supports hydrodynamic lubrication

- Reduces friction and heat

- Prevents catastrophic damage during overloads

Rebabbitting Services by R A Power Solutions

R A Power Solutions specializes in:

- Rebabbitting turbine bearings

- Babbitt bearing repair at site or workshop

- Reverse engineering & restoration of damaged bearings

- Rapid dispatch of technicians worldwide

Our team diagnoses root causes, not just symptoms and helps prevent recurring failures.

For any information regarding Babbitt bearings, crankpin bearings, rebabbitting of bearings, and Babbitt white metal, please email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

A: Rebabbitting is the process of removing worn Babbitt metal from a bearing shell and applying a fresh layer to restore its performance.

A: It’s needed when bearings lose lubrication efficiency, show scoring, or fail under load. Rebabbitting brings them back to near-new condition.

A: Typically, a few days, depending on bearing size, inspection needs, machining, and casting time.

A: Large industrial, marine engine, turbine, pump, and compressor bearings with Babbitt linings can all be rebabbitted.

A: Yep—rebabbitting is usually far more cost-effective, especially for large or custom bearings that are expensive to replace.