White Metal Babbitt Bearing | Rebabbitting of Bearing – RA Power Solutions

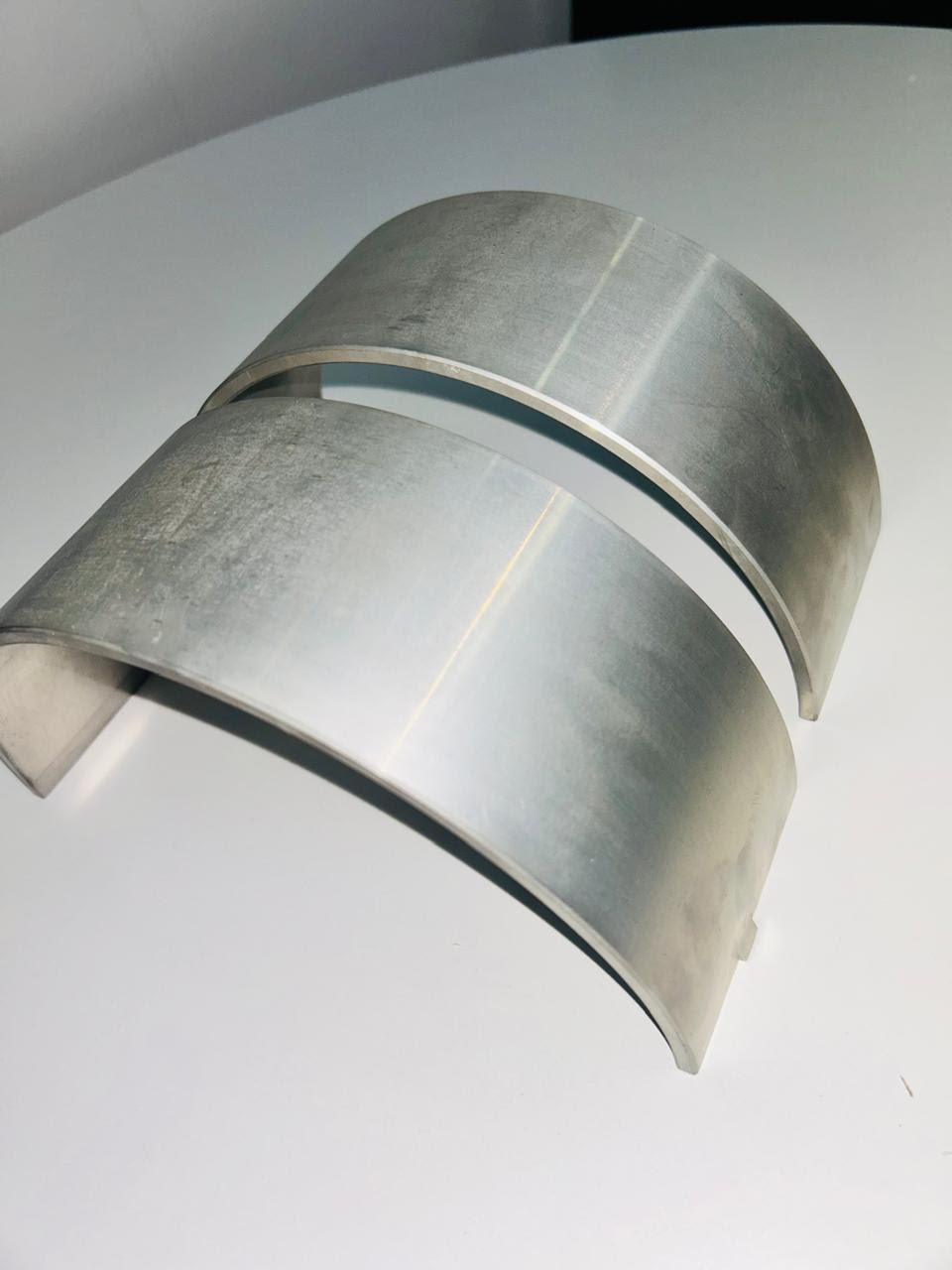

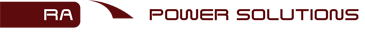

Bearings play a critical role in heavy-duty machinery such as pumps, turbines, engines, and alternators. White metal babbitt remains one of the oldest yet most effective bearing materials. At RA Power Solutions, we specialize in manufacturing and rebabitting white metal bearings, breathing new life into worn bearings with precision and quality.

What Is White Metal Babbitt Bearing?

We manufacture white metal babbitt bearings from equipment drawings or bearing samples. We maintain stringent quality control norms throughout the process.Our centrifugal rebabbitting system ensures excellent bonding between the base metal and the white metal.

The white metal after centrifugal casting has a dense surface without any pin holes or blow holes, which results in satisfactory performance and long life of the white metal babbitt bearing.

We use the latest in-house equipment for rough and final machining. This ensures accurate maintenance of all critical dimensions.

Why and When Do You Need Rebabbitting?

Over time, wear and tear on bearings can lead to:

- Ovality and taper — the bearing bore loses its perfect roundness or becomes tapered.

- Surface damage — from corrosion, pitting, fatigue, or embedding of foreign particles.

- Loss of material — worn-out surfaces can no longer support loads or flow lubrication properly.

Rebabbitting is the process of restoring or replacing the white metal layer so that the bearing can return to its original specification and performance.

Rebabbitting of old white metal bearings is undertaken, which develops taper and ovality or gets damaged. We are exporting bearings regularly to Singapore, Indonesia, Nigeria, the UK, South America, Sri Lanka, Greece, Dubai, Qatar, etc.

For more information, please email us at White Metal Bearings email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

A white metal babbitt bearing is a type of sliding bearing lined with a soft alloy (babbitt) that reduces friction, absorbs shocks, and protects shafts from wear.

Over time, babbitt bearings suffer from wear, ovality, taper, or surface damage. Rebabbitting restores the bearing’s original geometry and performance without needing a complete replacement.

Rebabbitting involves removing the old babbitt layer, applying fresh white metal (commonly via centrifugal casting), and machining it to precise tolerances.

At RA Power Solutions, bearings up to 1500 mm in bore diameter can be rebabbitted or newly manufactured.

Yes. Even if the OEM no longer manufactures the part, we restore or replicate bearings from samples or drawings. We use rebabbitting techniques for the process.