White Metal Babbitt Bearing Manufacturer – RA Power Solutions

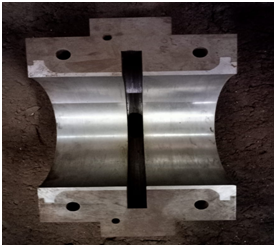

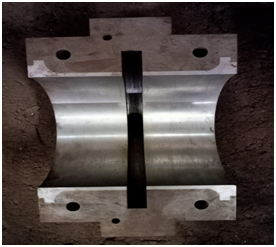

At RA Power Solutions, we specialize in manufacturing top-quality White Metal Babbitt Bearings and offer professional rebabbitting services, catering to bore sizes up to 1500 mm. Through our advanced centrifugal casting technique, we deliver unmatched bond strength and extend the lifecycle of your equipment.

Why Choose Our White Metal Bearing Services?

Whether you’re dealing with diesel engines, steam or hydro turbines, or heavy-duty machinery, our rebabbitting solutions ensure precision and durability:

- New Manufacturing & Rebabbitting Expertise: Create new white metal or tri metal bearings and restore worn ones using our centrifugal casting process, designed for superior bonding and longevity.

- Customized for Diverse Applications: From fan and alternator bearings to tilt-pad and pillow block bearings, we repair and fabricate bearings across various industrial domains.

Our Proven Process

With over 45 years of industry experience, our methodical approach is engineered for excellence:

- Comprehensive Inspection & Reporting

We assess the bearing’s condition and deliver detailed reports for transparent service decisions. - Precision Preparation

Removal of worn materials, cleaning, and surface repair ensures a solid foundation for rebabbitting. - Centrifugal Re-Babbitting

Our specialized casting method ensures optimal metal bonding and reliability. - Machining & Finishing

We maintain strict OEM tolerances to restore functionality with precision. - Rigorous Inspection & Bond Validation

Every bearing is carefully examined—bond quality is documented, and approval is provided for installation. - Installation Assistance

We offer guidance during installation to guarantee seamless integration as per your requirement.

What Sets Us Apart

- Advanced Centrifugal Casting Technology

Ensures dense, durable bonding of white metal to steel liners for enhanced performance. - Expert Team & Facilities

Skilled professionals supported by state-of-the-art machining and quality assurance capabilities. - End-to-End Quality Oversight

From pre-setup inspections to post-service installation, we ensure excellence at every step.

For more information regarding rebabbitting of bearing and White Metal Bearing Rebabbitting Services, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

Rebabbitting is the process of replacing worn white metal lining in bearings to restore performance and extend service life.

They are widely used in diesel engines, turbines, compressors, alternators, and heavy machinery.

Through centrifugal casting, ensuring strong bonding and longer operational reliability.

We manufacture and rebabbitt bearings up to 1500 mm bore size.

With 45+ years of experience, advanced technology, and strict quality checks, we ensure OEM-grade reliability.