White Metal Bearing | White Metal Babbitt Bearing

With over four decades of experience, RA Power Solutions leads in the design, development, manufacturing, and repair of white metal Babbitt bearings.

The manufacturing of new bearings and repair of old white metal Babbitt bearings is done for customers from all sectors of industries and applications, like as electric motor, fans, pumps, marine, diesel engines, turbines, alternators, rolling mills, etc.

Manufacturing of White Metal Bearings?

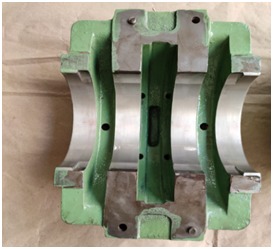

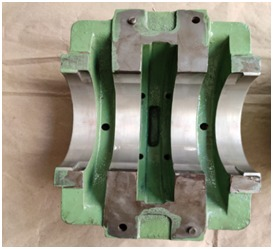

We manufacture bearings up to 1500 mm in diameter. We carry out the babbitting of white metal strictly by the centrifugal process in a controlled temperature environment. The centrifugal process offers clear advantages over static babbitting.

The machining of the bearings is undertaken strictly as per the drawing or a sample submitted by the end user. The in-house installation of CNC equipment enables us to maintain the bearing dimensions with close tolerance, which enhances the life of not only the white metal Babbitt bearing but of the rotating shaft on the White Babbitt Bearing assembled.

Development of White Metal Babbitt Bearing by Reverse Engineering

At times, there is a requirement for the development of bearings based on the old bearings available in the plant. This is common when the original equipment manufacturer has discontinued manufacturing of the main equipment or the white metal Babbitt bearing. The engineering department of RA Power Solutions develops a drawing of the damaged or worn-out bearing. Our team uses the dimensions taken from the old bearings provided by the client.

When old or worn-out bearings cause unclear dimensions, we incorporate them into the drawing. We use our four decades of experience in bearing design and development to ensure accuracy. We develop and manufacture the white metal Babbitt bearing based on the old bearing with a 100% guarantee.

White Metal Babbitt Bearing Repair Services

The repair of old and damaged white metal bearings is undertaken by us from 50 mm to 1500 mm bore size. We worldwide enjoy the reputation of executing repairs in no time. In case of an emergency.

Various quality checks are undertaken while repairing the old bearing, which include the following:-

- Removal of white metal from the old bearing at a controlled temperature.

- Inspection of bearing shell for cracks after removal of white metal.

- Hardness check of the naked bearing shell and removal of hard spots by scooping technology.

Metallurgical test of white Babbitt metal and use of a higher grade of white Babbitt metal.

We would like to strongly express that the bearings repaired by us after rebabbitting of white metal have a higher life cycle than the original bearings. In case of an emergency, we have the capacity even to repair the bearings within 24 hours.

Why Choose RA Power Solutions?

| Feature | Benefit |

| Wide Size Range | Supports bearings from 50 mm to 1500 mm, ideal for industrial applications. |

| Centrifugal Babbitting | Ensures flawless white metal bonding and performance. |

| Precision Finishing | CNC accuracy ensures durability and operational excellence. |

| Reverse Engineering | Effective solutions when OEM parts are unavailable. |

| Speed & Expertise | Rapid turnaround for urgent needs, with over 45 years of know-how. |

| Comprehensive QC | Multi-step inspection ensures long-term reliability. |

| Global Service | Trusted quality and logistics for worldwide clients. |

Contact Us

Ready to equip your machinery with precision-engineered or refurbished Babbitt bearings? Reach out to us:

Address: 411, 4th Floor, Unitech Arcadia, South City II, Gurgaon, Haryana – 122018, India

Phone: +91 95826 47131

Email: rajshahani@rapowersolutions.com | info@rapowersolutions.com

FAQs:

We manufacture white metal Babbitt bearings up to 1500 mm in diameter.

We use the centrifugal casting process in a controlled temperature environment for superior bonding.

Centrifugal babbitting ensures uniform bonding, fewer impurities, and longer bearing life compared to static pouring.

We provide both services,manufacturing of new bearings and rebabbitting/repair of old worn-out bearings.

Yes, our engineering team can reverse engineer bearings using worn-out samples and develop precise drawings.