Metal Stitching | Metal Locking | Crack Repair | Metal Lock Surgery

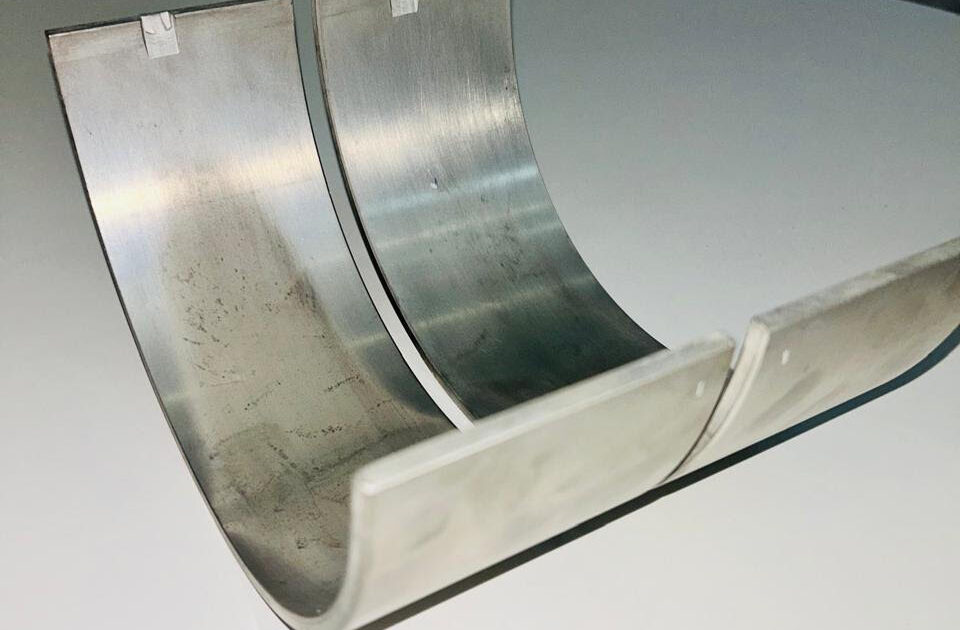

RA Power Solutions, having more than forty-five years of experience in the field of repair and maintenance of high-capacity engines, understands the importance of the parts. In case of damage to engine components or...