We have a pre-design process for rebabbitting of bearing designed by special experts. Highlights of the process are as follows:

I) Complete inspection of bearing and preparation of the report

We have a pre-design process for rebabbitting of bearing designed by special experts. Highlights of the process are as follows:

I) Complete inspection of bearing and preparation of the report

Diesel Engine maintenance, overhauling of diesel engine, and repair & replacement of the Crankshaft are undertaken by RA Power Solutions through experienced technicians. We leaders in providing Engine maintenance & overhaul services for the last 4 decades.

The main advantage of assigning a job of diesel engine overhauling & repair, and engine maintenance to RA Power Solutions is that we are experts in undertaking the onsite repair of the Crankshaft, Engine block, and all major services including repair of damaged casting. Metal locking & Metal Stitching, Rebabbitting of white metal bearings, and alternator services are offered in-house this reduces the downtime of the engine.

All our technicians carry valid Indian CDC & can execute the overhauling of diesel engines & diesel engine repair, marine & power plant diesel engine repair & maintenance while sailing.

We are giving below details of an overhaul of Wartsila 12V32 Engines executed in Panama, South America in November 2015.

Description:

I) Dismount and overhaul all cylinder heads, grind the valves, and replace all valve guide O ring seals. Checked cylinder head leakage and pressure testing of all heads at 5 bar

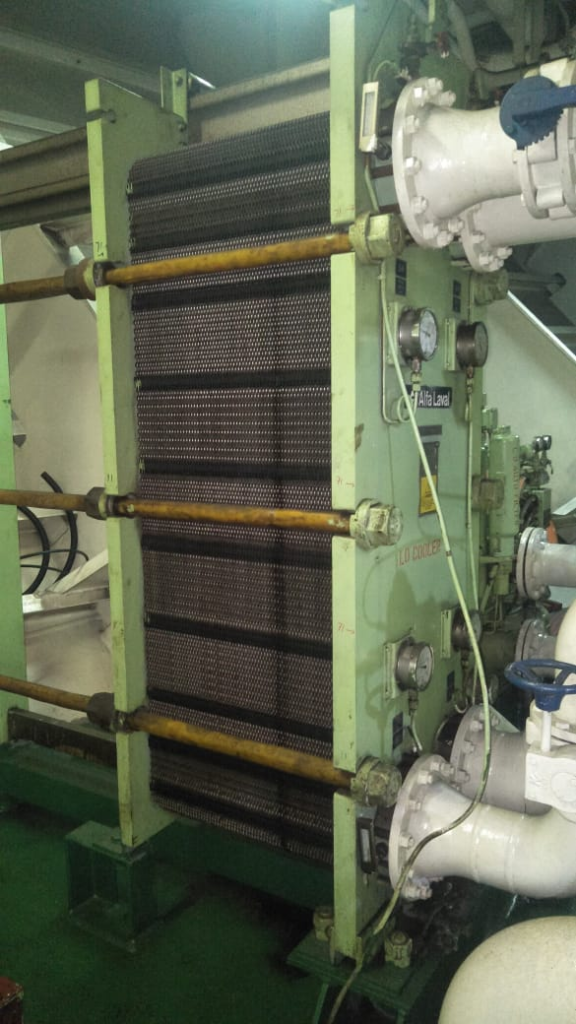

II) Overhaul the charged air coolers, Jacket water, and lubricating oil Alfa Laval plate heat exchangers.

III) Dismount and overhaul all ABB turbochargers, and renew the compressor and turbine side bearings.

IV) Withdraw all the pistons, take piston clearances, and check and clean piston ring landing and renewal of piston ring gudgeon pins, and big end bearings.

V) Clean inspect and de-glaze the cylinder liners. Replaced 7 bad liners

VI) Took Crank web deflection measurements after the renewal of main bearings.

VII) Polished the crankshaft and renewed all main and big-end bearings shells.

VIII) Dismount and overhaul all fuel injectors and pressure test the nozzles

IX) Dismount and overhaul the fuel pumps and replacement of delivery valves, plungers, and barrels.

X) Set the valve’s tappet clearances.

XI) Dismount and overhaul of both seawater and jacket water pumps replaced the mechanical seals and ball bearings.

The above engines after the repair and maintenance job undertaken by RA Power Solutions are operating satisfactorily.

The author is Mr. Raj Shahani Managing Director of RA Power Solutions having experience of almost four decades of working on high-capacity diesel engines, turbines, and rotary equipment.

For more information regarding diesel engine overhauling, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

or can visit our websites: https://www.rapowersolutions.com/, https://www.crankshaftgrindingrepair.com/

It is experienced that Diesel Power Plants & Shipping companies award the repair companies job of crankshaft grinding, repair & overhaul of the engine without checking their credentials. This results in a major breakdown & heavy losses to the clients.

RA Power Solutions has experience of 40 years in the field of repair of crankshafts, overhauling of high-capacity Diesel & major engine repair. The services extended by us are far better than the International standard and our service charges are the lowest in the world.

At RA Power Solutions, we understand the critical role that a crankshaft plays in the overall performance and durability of an engine. A properly functioning crankshaft is essential for smooth engine operation, power generation, and minimizing downtime. That’s why we offer comprehensive crankshaft inspection and crankshaft repair services to ensure the optimal performance of your machinery.

We have 24/7 availability of technicians with the necessary credentials & valid Indian CDC. They can travel to any destination in the world on short notice. We are the only company in the world that manufactures onsite crankshaft grinding equipment up to 700 mm & provides Crankshaft repair services as well. We have sold 70 onsite Crankshaft Grinding machines & have trained more than 150 technicians to undertake the repair of Crankshafts.

Stop availing of the crankshaft repair and Engine overhaul services from the local companies & avail the benefit of our experienced & low-cost services provided with the guarantee.

Conclusion: Regular crankshaft inspection and timely repairs are crucial for maintaining the performance, reliability, and longevity of your engine. At RA Power Solutions, our experienced technicians and advanced equipment allow us to provide top-notch crankshaft inspection and crankshaft repair services.

With our onsite repair capabilities and expertise in crankshaft machining and grinding, we are the leaders in delivering comprehensive solutions to ensure the optimal performance of your machinery.

Trust us to keep your engines running smoothly and efficiently. Contact us today to schedule an onsite inspection of the crankshaft or discuss your crankshaft repair requirements.

The author is Mr. Raj Shahani Managing Director of RA Power Solutions having experience of almost four decades of working on high-capacity diesel engines, turbines, and rotary equipment.

The company specializes in executing repairs i.e. metal stitching and metal locking, grinding and repair of crankshafts, crankshaft machining, rebabbitting of bearings, connecting rod reconditioning, and overhauling of Engines which have a serious problem resulting in immense savings to the owners.

For more information regarding onsite crankshaft inspection, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

RA Power Solutions is providing major engine overhauling & repair of high-capacity engines installed on the ship & in industries. Our technicians are experienced & they have worked with reputed engine manufacturers like Wartsila, Caterpillar, Mirrlees Blackstone, Cummins, etc.

Engine Overhauling services are extended by RA Power Solutions Pvt. Ltd. through our experienced engineers who have worked for engine manufacturers of repute like Mirrlees Blackstone, Ruston, Caterpillar, Wartsila, Cummins, etc. We have our standard procedure and technical formats which are strictly followed by our engineers at the time of overhauling of the engine. All the jobs of overhauling are undertaken with a guarantee.

RA Power Solutions has a large team of engineers & technicians available 24/7 all of them have valid Indian CDC & Palau CDC & can travel to any destination on short notice.

Discover top-notch engine-bearing solutions at RA Power Solutions. Our expert team offers high-quality engine bearing services for engines, ensuring smooth performance and longevity. From inspection to repair and replacement, trust us for precision and reliability in every aspect of engine bearings. Enhance your engine’s efficiency with RA Power Solutions today.

The author is Mr. Raj Shahani, Managing Director of RA Power Solutions Pvt. Ltd. He has 40 years of experience working on large crankshafts and Diesel Engines. He is on the board of directors of reputed shipping companies and companies having a large number of Diesel power plants.

For more information regarding engine bearing and engine overhauling, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Manufacturers of high capacity diesel engines are maintaining close tolerances in terms of taper and ovality of crankpin and main journal diameter of the crankshaft. The maintenance of close tolerances and high surface finish results in the generation of more power, longer life of crankshaft and bearing, less noise level, low vibration, friction, and better fuel efficiency. RA Power Solutions has been working on crankshafts of marine engines and engines used for various applications with diameters ranging from 30 mm to 700 mm.

I) The Taper and ovality of the crankpin and the main journal are maintained between 0.02 mm to 0.05 mm depending on the diameter of the crankpin and main journal.

II) The surface finish of less than 0.25 RA value is maintained.

RA Power Solutions has observed that sometimes due to an emergency, to put back the engine into operation, the crankshaft crankpin and main journal are hand polished with emery paper, nylon rope, and other means. This has serious consequences for the CR pin and the main journal. A few of them are as follows:

I) Bearing line marks, and pitting marks are observed on the crankpin and the main journal of the crankshaft cannot be removed by hand polishing.

II) It is our experience that in the case of the development of taper and ovality, it can never be reduced and controlled by hand polishing. On the contrary ovality and taper increase.

III) The surface finish of the crankpin and main journal is of great importance.

IV) It is observed that by hand polishing the marks can never be removed fully. Thus the desired surface finish as per the manual cannot be maintained.

RA Power Solutions, during their work on high-capacity engines installed with clients, spread all over the world, have observed that in most cases hand polishing rather deteriorates the condition of the crankpin and main journal and in some cases results in the rejection of the crankshaft.

Recently one of our clients has 3 generators of MAN B&W 8L 23/30 had a problem in all crankpins having a standard diameter of 185mm. Bearing line marks and a rough surface were observed. All the crankpins were hand-polished by nylon wire and new bearings were used. The crankshaft failed within 20 minutes of the operation of the engines. A few photographs are given below:

RA Power Solutions have introduced a portable, lightweight onsite crankshaft grinding and polishing machine which is capable of grinding and polishing diameters ranging from 30 mm to 700mm. The onsite crankshaft grinding machine is revolutionary portable equipment that can be inserted from the inspection window of the engine block. There is no requirement for the removal of the crankshaft from the engine block.

RA Power Solutions specializes in crankshaft polishing, offering high-quality services to improve the performance and longevity of crankshafts. our skilled technicians utilize state-of-the-art equipment and cutting-edge techniques for precise and efficient crankshaft polishing. The use of a dedicated crankshaft polisher ensures that the polishing process is done with utmost precision and consistency.

On site crankshaft grinding and polishing machine is easy to operate and we also extend training to the buyer’s technicians. Inviting companies to polish of crankshaft is no longer required as it can be undertaken by your technicians with the portable onsite crankshaft grinding machine. You can save on the exorbitant amounts charged by European companies, which was their monopoly till the last few years.

More than 70 machines have been sold all over the world and are operating successfully.

The author is Mr. Raj Shahani, Managing Director of RA Power Solutions Pvt. Ltd. He has 40 years of experience working on large crankshafts and Diesel Engines. He is on the board of directors of reputed shipping companies and companies having a large number of Diesel power plants.

The crankshaft grinding and crankshaft polishing machine has been developed through consistent and focused R&D with field trials undertaken in different conditions.

For more information on crankshaft polishers, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

To avoid the crankshaft from rejection or to reduce the minimum diameter of the Crankpin and the Main journal after grinding companies all over the world are approaching RA Power solutions for onsite repair of the crankshaft and crankshaft repair.

Ra Power Solutions has the expertise of successfully repairing more than 10,000 crankshafts for different applications and diameters ranging from 30 mm to 700 mm. There are companies based in Europe that had a monopoly in onsite grinding and crankshaft repair and were charging exorbitantly.

By introducing onsite repair of the crankshaft, RA Power Solutions has bought a revolution by executing onsite crankshaft repair far better than international standards and at the lowest price.

In this time of recession when shipping companies and large industries are passing through difficult times repair of the crankshaft, maintenance, and overhauling of diesel engines and all services related to engine room offered by RA Power Solutions have resulted in considerable savings for the shipping companies and heavy Engineering organizations having Diesel power plants.

All the crankshaft reconditioning & crankshaft refurbishment jobs undertaken by RA Power Solutions are guaranteed satisfactory performance.

RA Power Solutions is the only company in the world that apart from providing onsite repair services also sells onsite crankshaft grinding machine capacities ranging from 30 mm to 700 mm. More than seventy crankshaft grinder machines have been sold worldwide. Hundreds of technicians have been trained to execute successful repairs of crankshafts onsite.

We are a leading expert in crankshaft refurbishment, offering top-notch services to clients across various industries.

For your requirement of crankpin machining, onsite crankshaft grinding crankshaft repair, and crankshaft refurbishment, you may email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Overhauling and Maintenance of Diesel Engine undertaken as per the manufacturer’s recommendations is of great importance for the satisfactory performance of the main engine and auxiliary engines on board a vessel and installed in power plants.

RA Power Solutions undertakes complete overhaul, maintenance, and repair of engines and have experience of more than 40 years in this field. We have a team of technicians and engineers who have experience and have worked with the reputed engine manufacturers.

We follow the guidelines mentioned in the maintenance manual of the engine manufacturer religiously which enhances the life of the engine and results to satisfactory performance.

The main advantage of engine overhaul and engine maintenance services extended by RA Power Solutions is that we have in-house facilities for reconditioning of major components like crankshaft, engine block, connecting rods, cylinder heads, cylinder liners, etc. We also undertake rebabbitting of white metal bearings and crack repair of cast iron and Aluminium components by metal locking and metal stitching process.

The reconditioning of the parts and overhaul of the engine remains the responsibility of RA Power for which we stand guarantee. We promise the following for engine overhaul and engine repair services:

I) The highest quality of engine overhaul and engine repair services.

II) Expertise in calibration and replacement of crankshaft

III) The fastest possible turnaround time due to the experience of our technicians.

IV) Constant improvement in the overhaul of the diesel engine and diesel engine repair services.

V) Dedicated customer service staff available 24X7 with valid CDC.

VI) We have a record of repair, overhaul, and maintenance of over 10,000 Engines.

RA Power Solutions is a trusted name in the world of repair of diesel engines. With years of experience and a team of skilled technicians, they specialize in the comprehensive repair of diesel engines. Whether it’s a minor issue or a major overhaul, RA Power Solutions has the expertise to diagnose and fix problems efficiently, ensuring that diesel engines run at peak performance.

For more information related to the repair of diesel engines, or engine repair services, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

White metal babbitt bearings are manufactured by RA Power Solutions for all applications like engines, pumps, turbines, alternators, and rotatory equipment.

The white metal babbitt bearings are manufactured as per the drawing or as per the sample of the bearings of the equipment which are no longer produced by the original manufacturer. Stringent quality control norms are followed at the time of manufacturing of white metal bearings. The centrifugal system followed for the rebabbitting of white metal is used which ensures an excellent bonding between the base metal and white metal.

The white metal after centrifugal casting has a dense surface without any pin holes or blow holes which results in the satisfactory performance and long life of the white metal babbitt bearing.

The rough and final machining and maintenance of various critical dimensions are maintained by using in-house latest design of equipment. White metal babbitt bearings are manufactured as per international standards maintaining close tolerances. We have the facility to manufacture white metal babbitt bearing up to the outer diameter of 1500 mm.

Rebabbitting of old white metal bearings is undertaken which develops taper and ovality or gets damaged. We are exporting bearings regularly to Singapore, Indonesia, Nigeria, the UK, South America, Sri Lanka, Greece, Dubai, Qatar, etc.

Babbitt Metal Supplier | White Metal Babbitt Manufacturer

Manufacturers of non-ferrous metals such as tin, lead, copper, antimony, zinc, and aluminium produce white metal for the heavy-duty engineering industry, diesel engines, turbines, and alternators. The tin based Babbitt white metal manufactured qualifies ASTM, SAE, and federal specifications of Babbitt metal. Being an ISO 900:2015 certified company, we provide detailed metallurgical analysis reports with the Babbitt white metal manufactured and supplied by us. The quality of the white metal is assured and is guaranteed.

For more information, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

RA Power Solutions having more than forty years of experience in the field of repair and maintenance of high-capacity engines understands the importance of the parts.

In case of damage to engine components or cracks, RA Power Solutions undertakes repair onsite by metal stitching or metal lock surgery. We are considered to be the leaders in this field as we use the master lock, masterpiece, keys and consumables of high quality imported from the UK.

Our technicians are highly experienced. Crack repair and repair of damaged casting components can also be executed while sailing the Vessel.

Following is the process of metal locking, metal stitching, and its advantages.

The Metal Stitching process is accepted as the method of repairing all cracked, broken and damaged casting in cast iron, aluminium and steel.

It is observed that due to accidents or continuous running of the engine cracks develop in grey cast iron, aluminium, and Cast Steel Components. There is no need for disassembly of the equipment and getting it repaired by the welding process. We undertake the repair of cracks and badly damaged components by metal stitching and metal lock surgery process.

This method of crack repair is proven and is widely used all over the world. The services of crack repair in Grey Cast Iron, Aluminium and Cast Steel Components by metal stitching and metal locking are extended by us worldwide on a 24*7 basis.

We have a dedicated team that undertakes crack repair of cast iron and repair of damaged casting. Special pneumatic tools, locks and keys are used to execute the repairs. All the jobs of crack repair in Grey Cast Iron, Aluminium and Cast Steel Components executed by us are guaranteed for satisfactory performance.

We extend metal stitching services all over the world including countries like Brazil, Egypt, Panama, Russia, Argentina, Ecuador, Czech Republic, Senegal, Fiji, France, Germany, Dubai, Kenya, Chile, and Mexico.

For more information on metal lock surgery, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

RA Power Solutions has experience of forty years in onsite grinding and polishing of crankshaft diameters ranging from 30 mm to 700 mm. The onsite grinding and repair are executed by experienced technicians. We use a portable crankshaft grinding machine which is specially developed to undertake crankshaft grinding and crankshaft polishing within the tolerances stipulated by the manufacturer.

It is possible to undertake crankshaft grinding and crankshaft polishing while the vessel is sailing.

The crankshaft grinding machine used for crankshaft repair is manufactured of Titanium alloy which absorbs the vibrations and facilitates to maintain the close tolerance within 20-30 microns. We are the world leaders in onsite repair and offer crankshaft grinding Services at the lowest price with international standards. All the crankshaft repairs undertaken by us are guaranteed for satisfactory performance of the crankshaft and engine.

RA Power Solutions is a renowned crankshaft grinder manufacturer, known for its cutting-edge technology and expertise in the field of crankshaft repair and restoration. With years of experience and a skilled team of professionals, we have earned a reputation for delivering top-notch grinding machines that ensure precision and efficiency in crankshaft reconditioning.

Whether it’s for marine engines, compressors, or industrial machinery, RA Power Solutions’ crankshaft grinders are designed to meet the highest industry standards, making them the preferred choice for clients worldwide.

As a leading crankshaft grinder manufacturer, RA Power Solutions is committed to providing its customers with cutting-edge technology and exceptional machinery that ensures the utmost accuracy and reliability in every grinding process.

For more information regarding onsite crankshaft grinding machine suppliers, and in situ crankshaft grinding machine suppliers, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.