Rebabbitting Services offered by us of last more than four decades of experience applies latest generation of ultrasonic testing equipment and calibrated measuring devices to assure accurate dimensional and bonding of white metal with the shell after rebabbitting of Bearing is executed.

Rebabbitting includes following:

- Centrifugal Casting of white metal up to 1500 mm. Inner Diameter.

- Certified ASTM grades of Babbitt material is used.

- In-house Ultrasonic Testing done by qualified level three technicians.

- Magnetic particle test and Hardness Test of shell is done before and after rebabbitting.

- Final Inspection Reports prepared.

- All procedures meet or exceed OEM Specifications

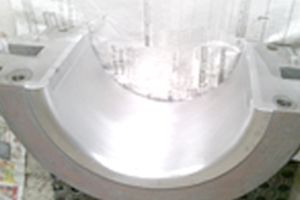

Centrifugal Casting for Babbitting of bearing and White Metal Bearing

- By rotating a bearing at the proper RPM, the molten Babbitt material can be poured under pressure. This centrifugal force combined with rapid cooling will provide the best bonding with the bearing shell

- Centrifugal babbitting process ensures that the poured Babbitt material is free of impurities.. Thus providing the best bonding strength, and considerable increase in the life of your bearing.

- For every bearing rebabbitt by RA Power we furnish ultrasonic bond certification, Magnetic particle testing report and dimensional inspection report. On demand we can arrange third party inspection of Babbitt bearings by Lolyds, Dnv, Registrar of shipping and other inspection agencies.

- We also maintain an inventory of certified Babbitt material allowing grade to match any OEM specification of babbitt that your bearing would require.

For more information regarding babbitting process and bearing remetallic, please email us on info@rapowersolutions.com

babbitting process

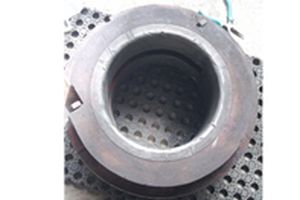

Rebabbitting of turbine bearing

Rebabbitting of Pedestrial bearing

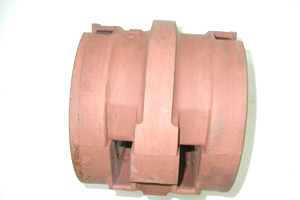

Pedestrial bearing for rebabbitting

Pedestrial bearing for rebabbitting