Introduction:

In the world of engine rebuilding and maintenance, precision and quality are of utmost importance. One crucial aspect that directly affects an engine’s performance is the condition of its crankshaft. To ensure optimal functionality, crankshafts often require machining, grinding, and polishing.

In this blog post, we will delve into the realm of crankshaft machining equipment, exploring the significance of crankshaft grinding and polishing machines and highlighting the advanced solutions offered by RA Power Solutions.

RA Power Solutions has been extending on-site crankshaft repair services for the last forty years. The crankshaft grinding and crankshaft machining are done onsite without removing the crankshaft from the engine block. This reduces the downtime of the equipment and results in considerable saving as it does not require packing, or transportation of the crankshaft to the designated workshop and this is now outdated.

RA Power Solutions has introduced a portable, lightweight, easy-to-operate onsite crankshaft grinding and crankshaft polishing machine which has been welcomed by the industries. More than 70 crankshaft grinding and crankshaft polishing machines have been sold worldwide to shipping companies, diesel power plants, hydro and thermal power plants, repair workshops, etc.

We continuously receive feedback from our existing customers confirming their full satisfaction where the performance of the crankshaft grinding and crankshaft polishing machine is concerned.

The clients who were availing the services of crankshaft repair companies based in Europe and the UK and spending large amounts now can undertake the repairs themselves by using crankshaft grinding and crankshaft polishing machines. Thus bringing down the cost of repair considerably.

Crankshaft Refurbishment

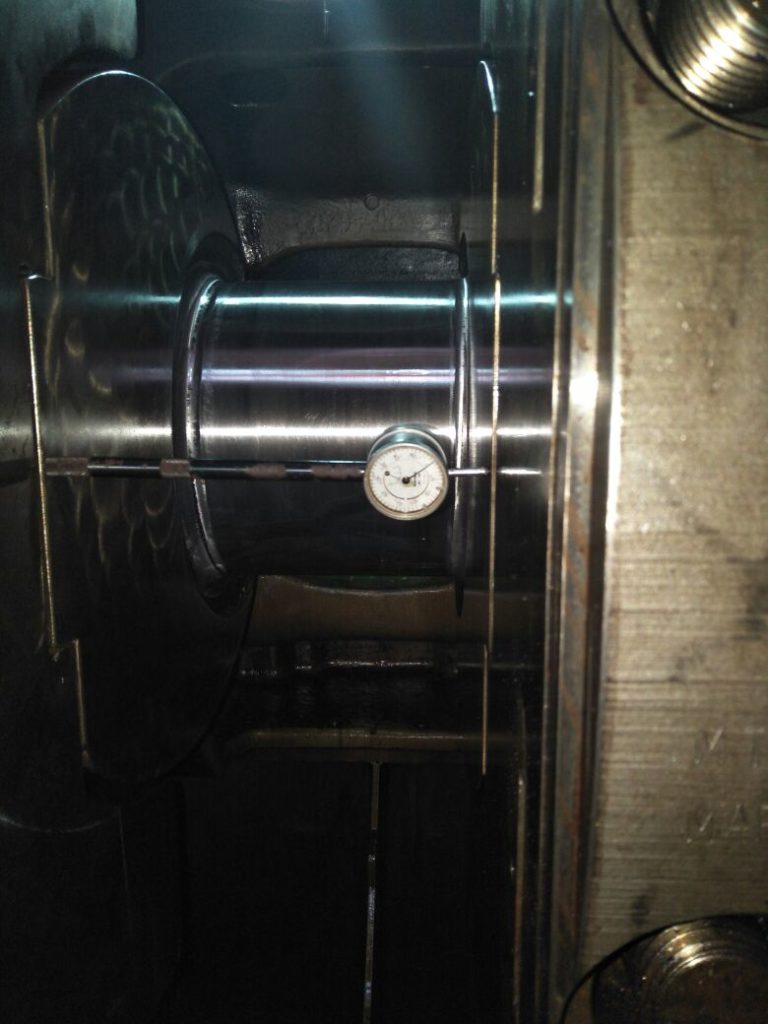

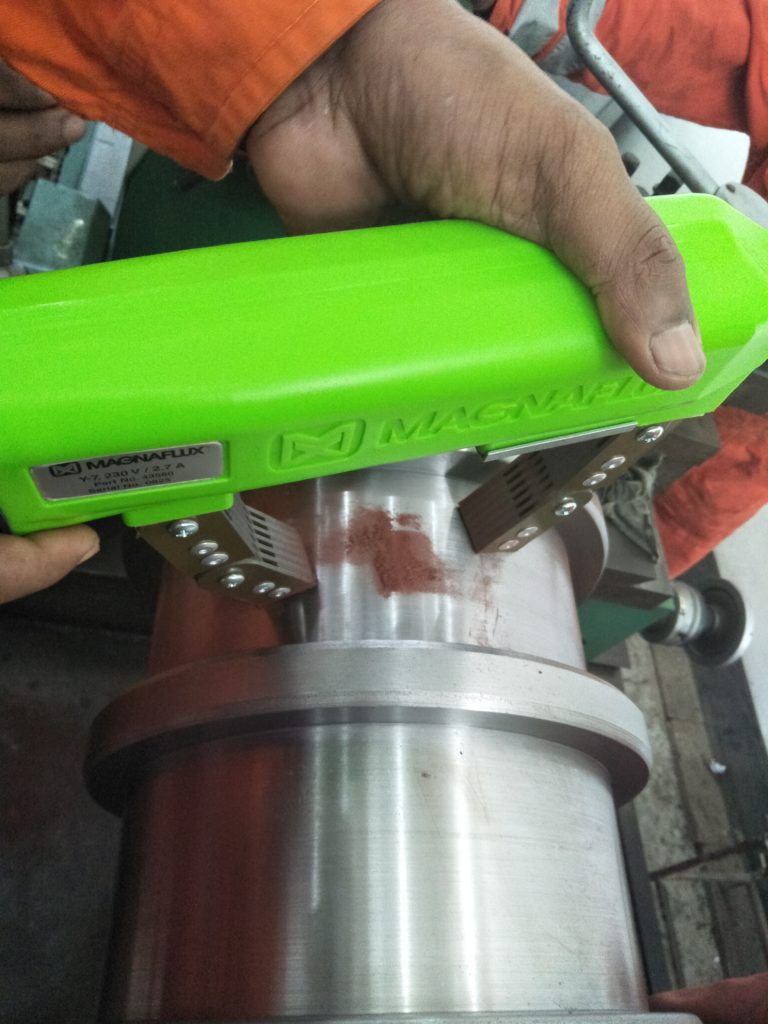

We think that whenever the engine is taken up for overhaul, the crankshaft should be calibrated and refurbishment should be done. In most cases, due to continuous running bearing line marks, pitting, and rough surface are observed on the crankpin and main journal diameter of the crankshaft. In this situation, it is advised that crankshaft refurbishment should be undertaken which may cover grinding and polishing of main journals and crank pin diameter as the situation may be.

The onsite crankshaft grinding equipment and crankshaft polishing machine are supplied completely in all respects and are ready to use immediately upon arrival at the site. The machine is supplied generally with a pneumatic turbine and requires air at 7 kg/cm² and 90 CFM alternatively electric motor drive can also be supplied which is heavier than the pneumatic turbine. RA Power Solutions extends free training to the client’s technicians for the operation and maintenance of the crankshaft Grinder.

The machine is supplied in powder-coated steel boxes with clamps to hold it and can be taken by the technicians to various sites all over the world safely. The onsite crankshaft grinding and crankshaft polishing machine is available from 35 mm to 700 mm in terms of diameter.

The crankshaft grinding and polishing machines are also manufactured as per the client’s requirement and according to the space available at the site for the fitment of the machine.

Conclusion:

Crankshaft machining equipment plays a vital role in ensuring the performance and longevity of engines. With the help of advanced crankshaft grinding and polishing machines, engine rebuilders, and maintenance professionals can restore crankshafts to their original specifications, enabling optimal engine operation.

RA Power Solutions stands out as a leading provider of high-quality crankshaft machining equipment. Their cutting-edge solutions and experienced team ensure accurate and efficient restoration, elevating engine performance to new heights. When it comes to enhancing engine functionality, investing in top-notch crankshaft grinding equipment is undoubtedly a wise choice.

The author is Mr. Raj Shahani, Managing Director of the company. He has forty years of experience in providing onsite repair services of crankshafts, turbine shafts, tail shafts, alternator shafts, and complete engine repair services across the world. After extensive research and study, he has developed an onsite crankshaft grinding machine.

For any information regarding on site crankshaft grinding polishing machine, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.