Introduction to Babbitt white metal

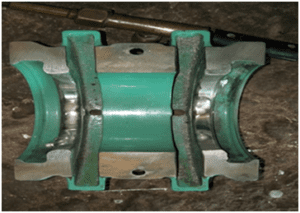

Babbitt alloys are well-known for their hard/soft composition. Babbitt metal has astonishing properties when it is utilized as a bearing material. We use Babbitt Metal to do bearing repairs or for the creation of new bearings. Babbitt white metal plays a very important role in the overall performance of bearings. Heavy rotatory equipment like Turbines, alternators, pumps, and Engines use white Babbitt metal to manufacture bearings.

Uses of babbitt metal:

- It is a soft, white non-ferrous alloy utilized in giving a bearing surface.

- It decreases friction so it’s recommended material to use in bearings repair and manufacturing of new white Babbitt metal bearings.

- It is used as a bearing material for High-capacity engine crankshafts.

- It displays excellent corrosion resistance and less tendency for isolation.

The use of babbitt metal is more in demand in this modern and technological world. The notable point of white metal manufactured by our company is that they are eminent for their brilliant performance.

Mainly, there are two leading babbitt materials: –

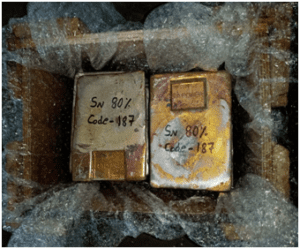

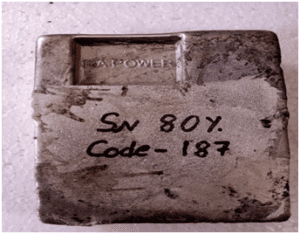

Tin-based babbitt – It contains 80% of tin alloy. Babbitt is a soft metal, the tin adds some hardness to its properties to proffer additional load-carrying capabilities. Tin-based babbitt bearings can be utilized in machinery and marine-related works.

Lead-based babbitt – It contains 75% or more than that of lead alloy. It provides good frictional capabilities. This babbitt is selected for high and low-speed machinery.

Conclusion

Babbitt white metal bearings have remained a trusted choice in various industries, thanks to their exceptional load-carrying capacity, low friction, and durability. When searching for Babbitt white metal manufacturers and suppliers, it is crucial to choose experienced professionals who offer high-quality, customized solutions and prioritize customer satisfaction. By partnering with reliable manufacturers, you can ensure the longevity and performance of your equipment, ultimately leading to increased productivity and reduced downtime.

At RA Power Solutions, we are committed to providing top-notch Babbitt white metal bearings that meet the highest industry standards. With our expertise, customization capabilities, and dedication to quality, we are the trusted partner for all your precision bearing needs. Contact us today to learn more about our Babbitt white metal manufacturing and supply solutions.

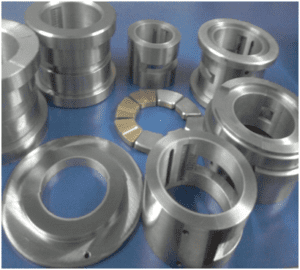

RA Power Solutions are well-known Babbitt white metal manufacturers and suppliers. We manufacture Babbitt white metal of distinct categories that are mainly used for rebabbitting of old bearings and manufacturing new Babbitt white metal bearings. Complete inspection protocol is followed of Babbitt white metal before despatch to any of our customers and this defines the customer’s trust towards our company. Presently, the babbitt metal is exported to countries like Bolivia, Saudi Arabia, Dubai, Kuwait, and about forty countries.

Remember, when it comes to Babbitt white metal, choose the experts who deliver precision and reliability!

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions). He has forty years of experience in the field of engine repair and is a technical adviser to various shipping and heavy industries based all over the world.

For more information related to leading white metal exporters, Babbitt bearings suppliers, babbitt suppliers, Babbitt metal suppliers, white metal manufacturers, and suppliers, and manufacturers of white metal please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.