Crankshaft Reconditioning | Crankpin Machining | Crankshaft Refurbishment

To avoid the crankshaft from rejection or to reduce the minimum diameter of the Crankpin and the Main journal after grinding, companies all over the world are approaching RA Power solutions for onsite repair of the crankshaft and crankshaft repair.

RA Power Solutions has the expertise to successfully repair more than 10,000 crankshafts for different applications and diameters ranging from 30 mm to 700 mm. There are companies based in Europe that had a monopoly in onsite grinding and crankshaft repair and were charging exorbitantly.

In this time of recession, shipping companies and large industries are going through difficult times. RA Power Solutions offers crankshaft repair, diesel engine maintenance, overhauling, and complete engine room services. These solutions have resulted in considerable savings for shipping companies and heavy engineering organizations with diesel power plants.

Procedure for Successful Onsite Repair of the Crankshaft:

- Thorough cleaning of the Crankshaft/Main Journal, which is damaged.

- Visual inspection of radius fillet, lubrication oil hole, surface finish, and other parameters of Crankpin and Main journal.

- Conduct NDT tests by qualified technicians with the latest instruments for crack repair, hardness test, surface finish, dimensional inspection, etc.

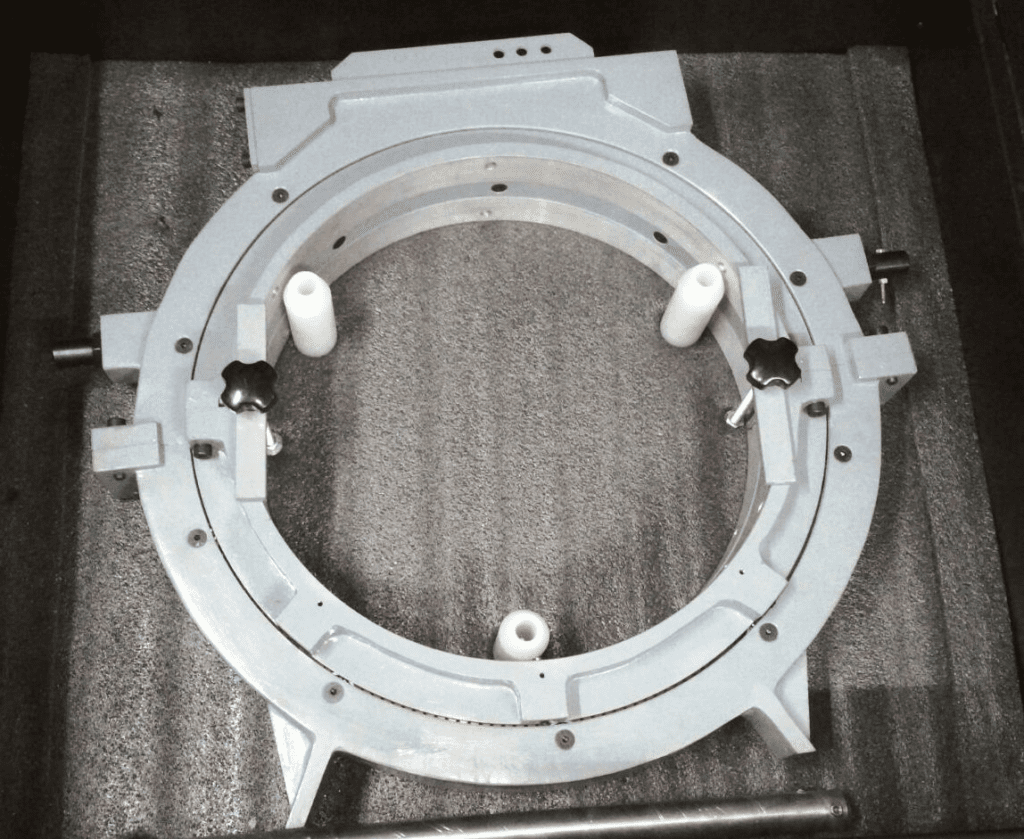

- Selection of the correct onsite tooling to execute the grinding and polishing.

- Final inspection by senior technicians of the crankshaft and preparation of reports.

RA Power Solutions guarantees satisfactory performance for all crankshaft reconditioning and refurbishment jobs. RA Power Solutions is the only company in the world that, apart from providing onsite repair services, also sells onsite crankshaft grinding machine capacities ranging from 30 mm to 700 mm. Customers worldwide have purchased more than seventy crankshaft grinder machines. We have trained hundreds of technicians to execute successful onsite crankshaft repairs.

We are a leading expert in crankshaft refurbishment, offering top-notch services to clients across various industries.

For your requirement of Crankshaft Reconditioning and Crankpin Machining, onsite crankshaft grinding, crankshaft repair, and crankshaft refurbishment, you may email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

They’ve repaired over 10,000 crankshafts in various applications.

Their process includes cleaning, visual inspection, NDT (non-destructive testing), hardness & dimensional checks, grinding/polishing, and final senior technician inspection.

Yes, all crankshaft reconditioning and refurbishment jobs are guaranteed to have satisfactory performance

By doing onsite crankshaft repair, overhauls, and diesel engine maintenance at competitive prices, saving shipping and heavy engineering companies significant costs.