Introduction:

White metal bearings play a vital role in the smooth and efficient functioning of industrial machinery. These specialized bearings are designed to withstand heavy loads, high temperatures, and extreme operating conditions. In Panama, where various industries thrive, the significance of white metal bearings cannot be overstated.

White metal bearings have vast applications. They are commonly used as engine bearings and bearings for turbines, pumps, crankshafts, alternators, etc. The white metal bearing has the basic property of reducing friction between the moving part and the bearing that can provide support to the crankshaft, camshaft, turbine shaft, alternator shaft, pump shaft, or any other type of shaft.

Whether it is in manufacturing plants, power generation facilities, or marine applications, white metal bearings provide essential support and ensure the reliable operation of rotating machinery.

From turbines to motors, pumps to compressors, these bearings enable seamless movement while minimizing friction and wear. In this section, we will share the importance of white metal bearings.

We will explore their benefits over other types of bearings and highlight their specific use cases across different sectors. By understanding the importance of these specialized components, businesses can make informed decisions when it comes to maintaining and optimizing their machinery’s performance.

So let us now embark on a journey through the world of white metal bearings and discover how they contribute to the success of Panama’s industrial landscape.

The Advantages of White Metal Bearings for Improved Performance and Reliability

White metal bearings offer various advantages when it comes to improving performance and reliability in various industries. In Panama, the utilization of white metal bearings has gained meaningful attention due to their exceptional characteristics and benefits.

One of the key advantages of white metal bearings is their superior load-carrying capacity. These bearings are designed to withstand heavy loads, making them suitable for demanding applications in industries such as mining, construction, and marine operations. Their ability to handle high loads provides a reliable and stable operation even under extreme conditions.

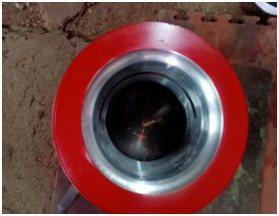

Another amazing advantage of white metal bearings is their exceptional resistance to wear and friction. The composition of white metal, which typically includes materials like tin or lead alloys, provides excellent lubrication properties that reduce friction and minimize wear between moving parts. This results in extended bearing life, reduced maintenance requirements, and enhanced overall performance.

In Panama’s humid climate or marine applications where saltwater can pose a challenge for traditional bearing materials, white metal bearings offer a perfect solution by ensuring long-lasting performance even in harsh conditions.

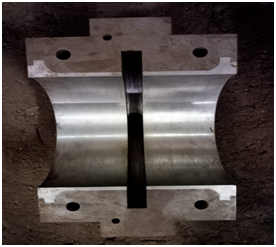

Additionally, white metal bearings have the advantage of being easily repairable or re-lined if required. Instead of replacing an entire bearing assembly when damage occurs or wear becomes significant over time, these bearings can be restored by replacing just the lining material.

The benefits offered by white metal bearings make them a preferred choice for industries in Panama seeking improved performance and reliability. Their ability to handle heavy loads while providing incredible resistance to wear, corrosion, and oxidation ensures optimal functionality even in challenging environments. With easy repairability options available when needed, these bearings prove to be a cost-effective investment that improves operational efficiency across various applications.

RA Power Solutions: The Leading Provider of White Metal Bearings in Panama

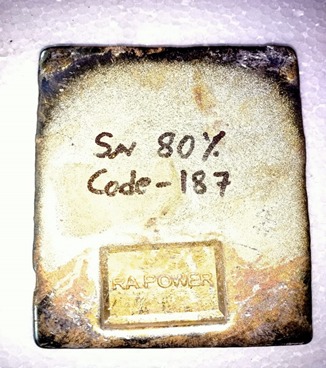

RA Power Solutions is proud to be recognized as the leading provider of white metal bearings in Panama. With our expertise, we have established ourselves as the go-to company for high-quality white metal bearings that meet the stringent requirements of various industries.

White metal bearings play a vital role in ensuring smooth and efficient operations across a wide range of applications, from heavy machinery to marine equipment. At RA Power Solutions, we understand the importance of reliable and durable bearings that can withstand excessive conditions and deliver optimal performance.

We adhere to strict quality control measures throughout the production process to ensure that our products meet international standards and exceed customer expectations.

We offer customized solutions tailored to specific requirements, ensuring that our white metal bearings provide optimal performance and longevity. In addition to providing top-notch products, we are committed to delivering excellent customer service. Our knowledgeable team is forever ready to offer technical support, answer queries, and guide you in selecting the right white metal bearing for your application.

When it comes to the best white metal manufacturers, metal bearings, and white metal bearings in Panama, RA Power Solutions stands head and shoulders above the competition. Trust us as your reliable partner for all your bearing needs!

Conclusion:

In conclusion, upgrading to white metal bearings offered by RA Power Solutions is a wise choice for those seeking superior performance and longevity. RA Power Solutions, with its expertise in the field of bearing manufacturing and reconditioning, offers top-quality white metal bearings that meet international standards.

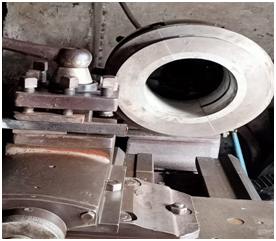

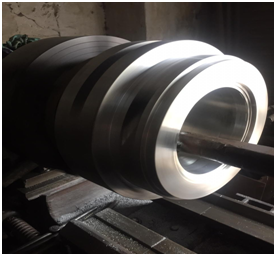

RA Power Solutions also manufactures Babbitt bearings as per the drawing and requirement of the client. We have in-house facilities to manufacture white metal engine bearings, white metal alternator bearings, white metal pump shaft bearings, white metal turbine bearings, white metal rotor shaft bearings, white metal crankshaft bearings, and white metal bearings for all sizes of shafts ranging from 60 mm to 1500 mm.

Upgrade your machinery today with RA Power Solutions’ white metal bearings in Panama for an unparalleled performance boost. Please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.