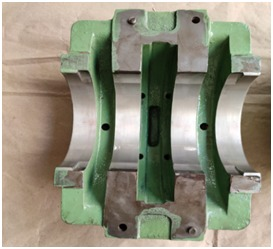

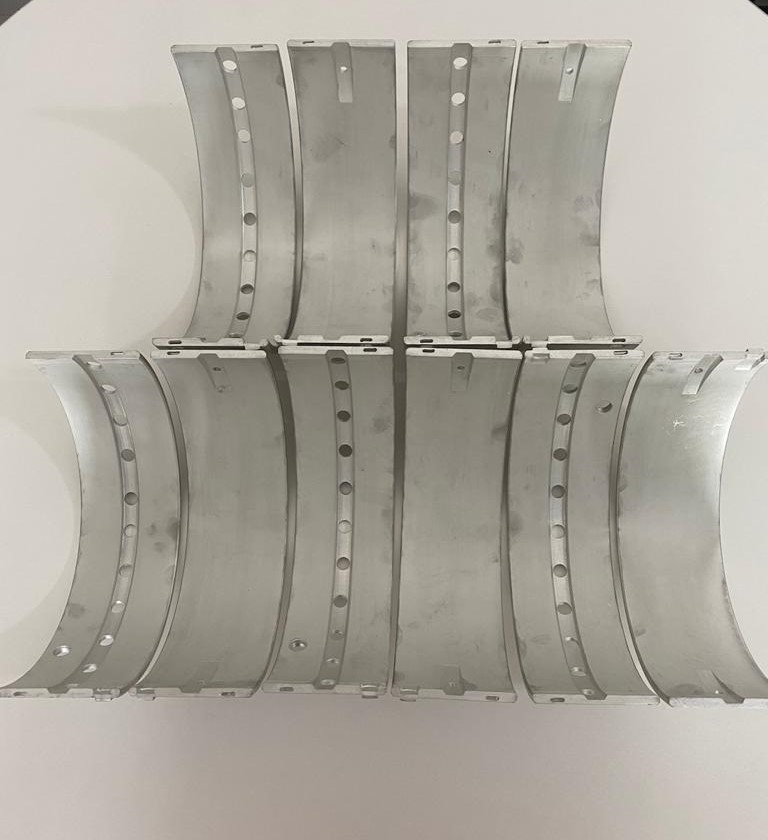

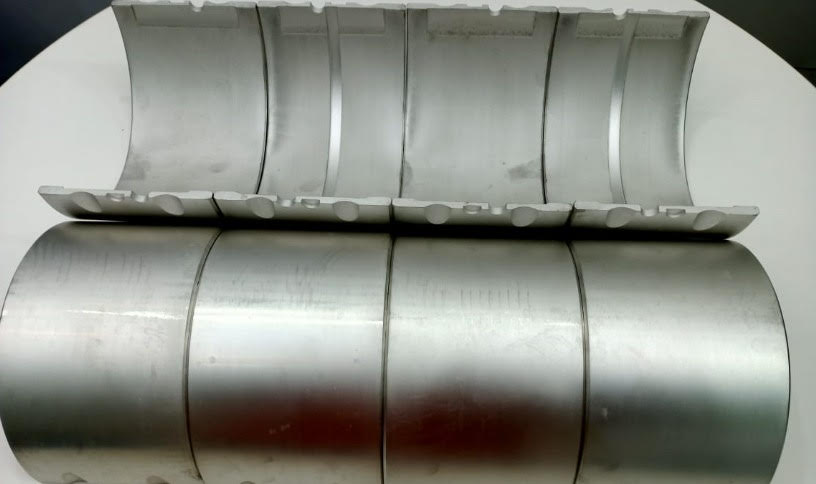

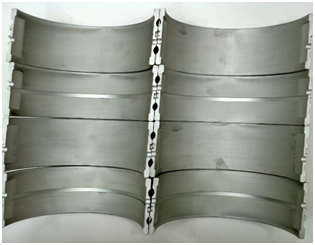

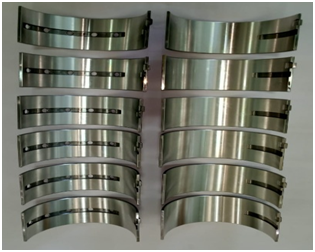

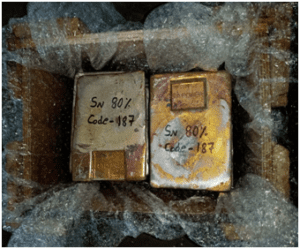

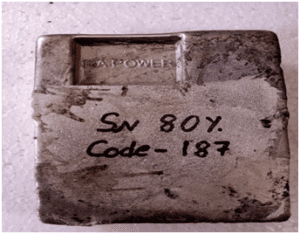

RA Power Solutions undertakes rebabbitting of old, worn out, and damaged bearings up to 1500mm diameter for large industrial and marine companies. The rebabbitting is undertaken using the different grades of Babbitt white metal as per international standards. All the bearings rebabbitting is undertaken by a centrifugal process which results in the perfect bonding with the steel casing of the bearings.

The rebabbitting operation executed by us has the following features:

- The white metal of the bearing is removed under the controlled temperature.

- The bare bearing steel casing is shot-blasted for proper cleaning.

- The bearing casing is subject to hardness test and all the hard spots are removed by scooping.

- The bearing casing is subject to crack detection by the MPI process.

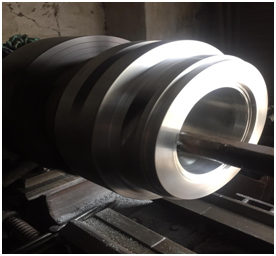

- The bearing is centrifugally cast.

- All the bearings after rebabbitting are subject to ultrasound tests to check the bonding with the base metal

- Final machining is done on CNC machines, maintaining close tolerance as per the requirements.

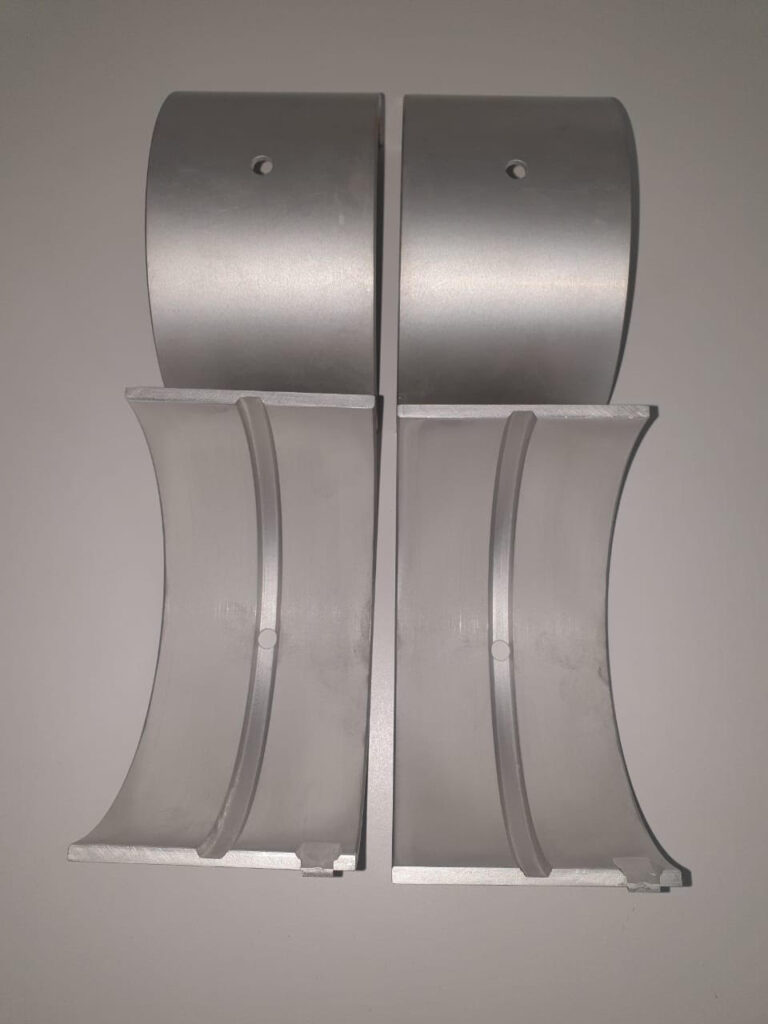

We manufacture Babbitt bearings as per the drawing and requirements of the client. We have in-house facilities to manufacture white metal engine bearings, white metal pump shaft bearings, white metal turbine bearings, white metal alternator bearings, white metal rotor shaft bearings, white metal crankshaft bearings, and white metal bearings for all sizes of shafts ranging from 60 mm to 1500 mm.

With a focus on customer satisfaction, RA Power Solutions caters to a diverse range of industries, including power generation, marine, and heavy engineering. Their white metal bearings are designed to withstand extreme conditions, providing long-lasting solutions that contribute to the efficiency and longevity of machinery.

We are dedicated to providing comprehensive solutions, including installation and maintenance services, ensuring that our clients experience seamless operations and minimal downtime

We are conveniently situated near New Delhi, India (International Airport) and can facilitate the necessary arrangements for import and re-export after repairs promptly and cost-effectively. This is the primary reason we serve more than 36 countries, meeting their critical needs for new white metal Babbitt bearings and providing rebabbitting services for damaged bearings.

For more information, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.