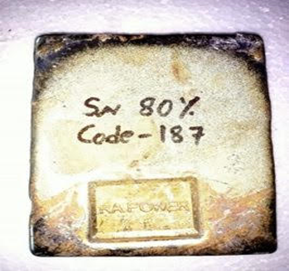

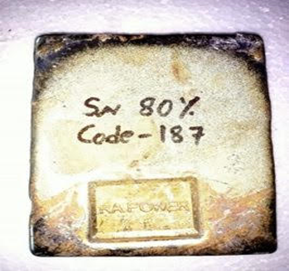

Babbitt White Metal Bearings for all applications are manufactured by RA Power Solutions Pvt Ltd. A company well-known all over the world for its quality, services, and products for over forty-four years.

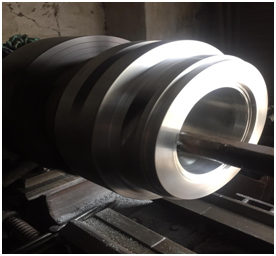

We follow a centrifugal casting process which has proved to be a better and successful process. The bonding between the babbitt white metal and base steel casting is achieved of high standard.

Manufacturing of New Babbitt White Metal Bearings is undertaken on the basis of a sample or a drawing provided by our client. The old bearings rebabbitting is undertaken maintaining the composition of babbitt white metal superior than the original. This increases the life of Babbitt white metal bearings.

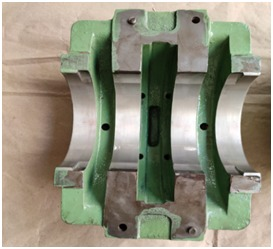

We have recently manufactured Babbitt White Metal Thrust Bearings for a company based in UK (United Kingdom) the design of bearing is quite complexed as we have to develop dedicated tooling for Machining of profiles.

The main Dimensions are as following:-

| Bearing Bore | 6.500 to 6.5005 Inches |

| Running Clearance (New) | 0.005 to 0.0075 inches Max. permissible 0.012 Inches |

| Thrust Bearings Length | 4.8665 to 4.8680 Inches |

The Bearings have been successfully developed and manufactured. RA Power Solutions Manufactures Babbitt White Metal Bearings up to 1500 MM in terms of diameter.

Developing and manufacturing bearings as large as 1500 mm in diameter is no small feat. It speaks volumes about RA Power Solutions’ expertise in metallurgy, precision engineering, and quality control. These bearings are crucial for ensuring smooth operation and longevity in industrial machinery, where performance and reliability are paramount.

For more details on Babbitt White Metal Bearings, babbitt white metal bearing manufacturer and repair, bearing manufacturing company please email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.