Introduction:

Welcome to the world of precision engineering and exceptional crankshaft grinding services in Tanzania. When it comes to ensuring the optimal performance & longevity of your engines, nothing compares to the expertise delivered by our skilled technicians.

With cutting-edge technology & a commitment to greatness, our crankshaft grinding services guarantee that your crankshafts will be converted to their original specifications, eliminating any spots that may hinder your engine’s efficiency.

Whether you are in requirement of standard repairs or complex custom solutions, our dedicated team is ready to deliver outstanding results, ensuring your engines run smoothly and reliably. Experience the epitome of quality & reliability with our professional crankshaft grinding services in Tanzania.

The Expertise of RA Power Solutions in Crankshaft Grinding Services

RA Power Solutions is a well-known name in the industry, offering top-notch expertise in crankshaft grinding services. With a strong presence in Tanzania, they have carved a niche for themselves with their amazing services in crankshaft repair, grinding, polishing, and inspection.

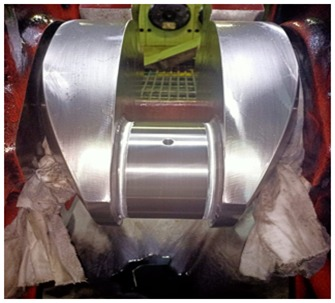

When it comes to crankshaft grinding, RA Power Solutions stands as a trusted partner for a wide range of clients. Their experienced technicians possess extensive knowledge and experience in handling various types of crankshafts, be it from marine engines, industrial equipment, or power plants.

The company’s expertise in crankshaft repair is second to none. They employ advanced techniques and cutting-edge equipment to repair damaged crankshafts to their original specifications, providing the highest level of precision and performance.

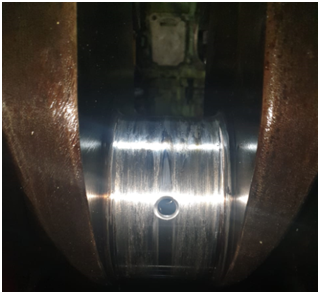

For those seeking crankshaft polishing services, RA Power Solutions offers a seamless process that results in smooth, mirror-like surfaces on crankshafts. The particular approach adopted during polishing ensures improved performance and reduced friction, resulting in improved efficiency & longevity of the crankshafts.

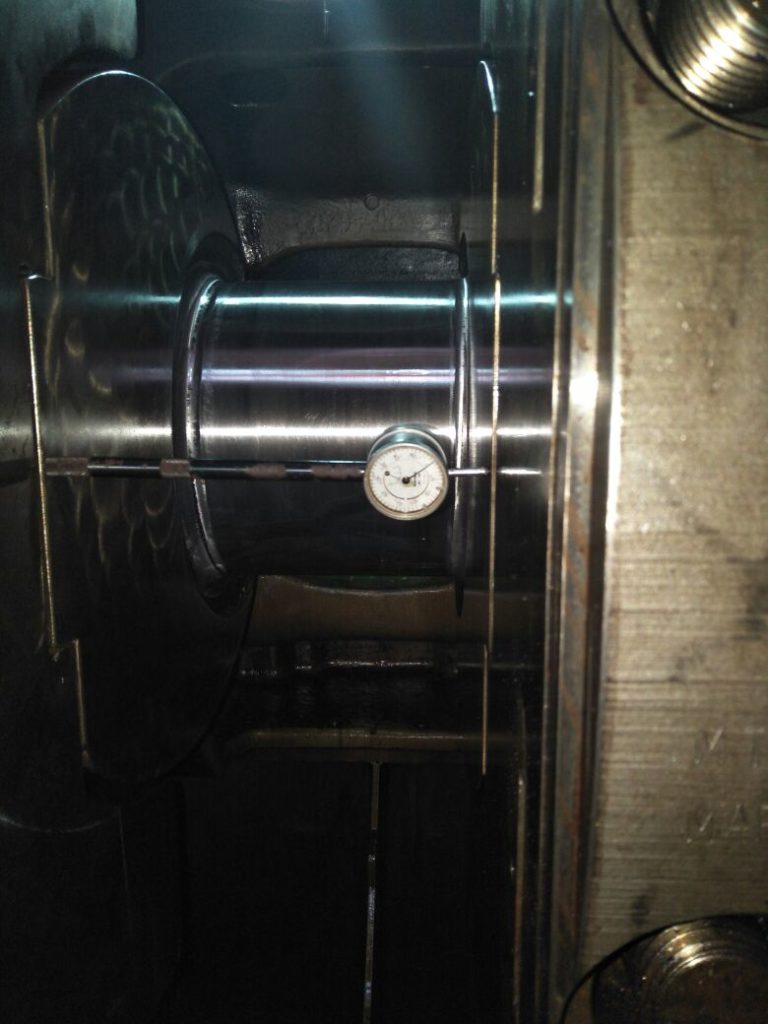

Crankshaft inspection is a critical aspect of their services, reflecting their dedication to delivering top-tier quality. Through advanced inspection methods, including non-destructive testing & dimensional analysis, RA Power Solutions ensures that every crankshaft meets the strictest industry standards before being returned to its rightful place.

RA Power Solutions stands as a leading authority in crankshaft grinding, repair, polishing, and inspection. Their expertise, coupled with a customer-centric approach, has earned them the trust & loyalty of clients across various industries, making them the go-to choice for all crankshaft-related needs.

The Benefits of Choosing RA Power Solutions for Crankshaft Grinding in Tanzania

When it comes to crankshaft grinding and repair services, RA Power Solutions stands out as a trustworthy and efficient choice. With their expertise and specialized equipment, they deliver a range of essential services that ensure optimal performance & durability of crankshafts.

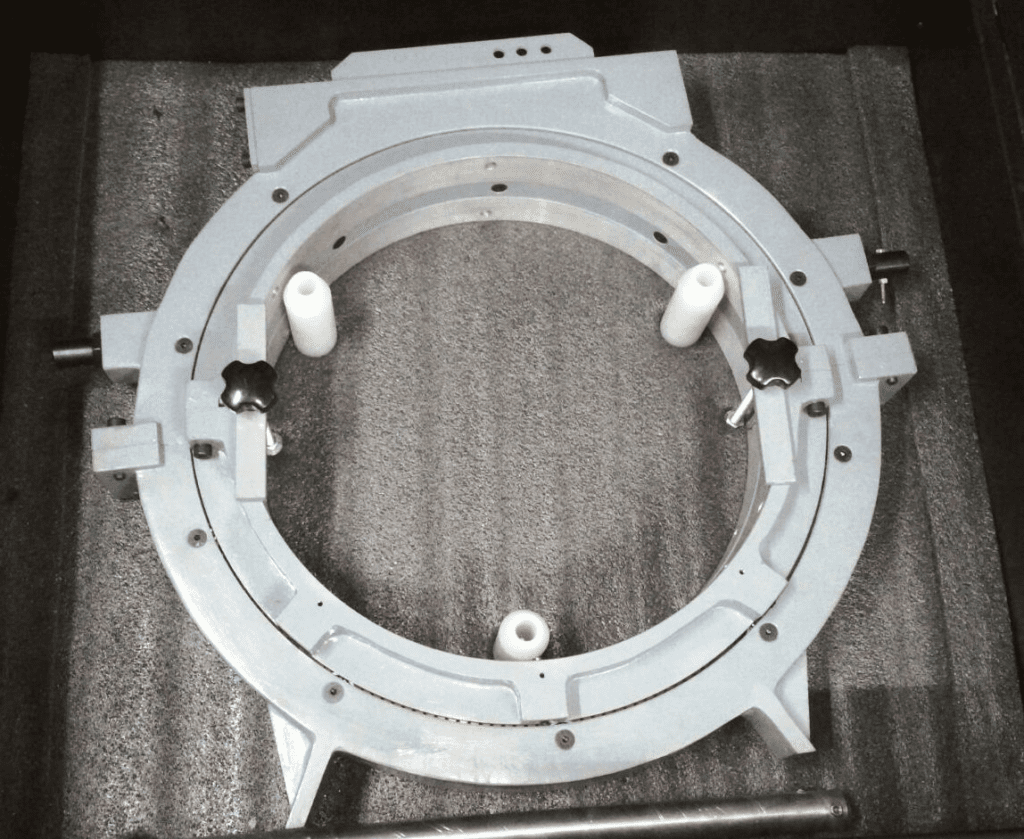

Crankshaft grinding is a crucial process for restoring the precision and smoothness of damaged crankshafts. RA Power Solutions boasts advanced grinding machinery & skilled technicians who can handle crankshafts of various sizes and designs. Their precise grinding techniques not only eliminate any surface irregularities but also help in restoring the original dimensions, leading to improved engine efficiency & reduced vibrations.

Another key service offered by RA Power Solutions is crankshaft repair. Whether it’s a minor crack or a major damage, their experienced team can effectively repair the crankshaft, saving clients from the cost of a full replacement. By employing state-of-the-art technologies & following industry best practices, they ensure that the repaired crankshafts recover their structural integrity, minimizing the risk of future failures.

RA Power Solutions also places significant emphasis on crankshaft inspection. A thorough inspection is crucial to determine any hidden defects or potential issues that could lead to catastrophic engine failure.

Choosing RA Power Solutions for crankshaft grinding, repair, polishing, and inspection in Tanzania brings multiple advantages. With their cutting-edge equipment & expertise, they ensure the highest quality standards are met, ultimately improving engine performance, increasing the longevity of crankshafts, and delivering customers with the peace of mind they deserve.

Crankshaft Grinding as a Preventive Maintenance Measure for Long-lasting Engines

Crankshaft grinding is a necessary preventive maintenance measure for ensuring the longevity & optimal performance of engines. In Tanzania, specialized services such as crankshaft grinding, crankshaft repair, crankshaft polisher, and crankshaft inspection are readily available to address possible issues with this crucial engine component.

Over time, the crankshaft can develop wear & tear due to constant operation, which can lead to inequalities and reduced engine efficiency. By utilizing professional crankshaft grinding services in Tanzania, engine owners can have their crankshafts restored to their original specifications, eliminating any irregularities and providing smooth rotation.

This process not only enhances engine performance but also prevents further damage to other engine parts, thus significantly extending the overall lifespan of the engine. Whether it’s a regular maintenance check or addressing a specific concern, relying on experienced professionals for crankshaft services in Tanzania is a smart investment for maintaining reliable, long-lasting engines.

Contact Us for Top-notch Crankshaft Grinding Services in Tanzania

Looking for top-notch crankshaft grinding services in Tanzania? Look no further than RA Power Solutions. We specialize in comprehensive crankshaft solutions, including crankshaft grinding, repair, polishing, and inspection services.

Our team of professional technicians is equipped with state-of-the-art machinery & years of experience, ensuring preciseness and efficiency in every project. Whether you require crankshaft repair, grinding, polishing, or inspection services, we have you covered.

With our commitment to quality and customer satisfaction, you can trust RA Power Solutions to deliver outstanding results for all your crankshaft requirements in Tanzania. For more information, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.