Introduction:

White metal bearings play a crucial role in various industries, ensuring the smooth and efficient operation of machinery. When it comes to reliable white metal bearing solutions in Greece, RA Power Solutions stands as a trusted provider. With their expertise and cutting-edge technology, they offer high-quality bearing services that meet the diverse needs of industries across the country.

What are White Metal Bearings?

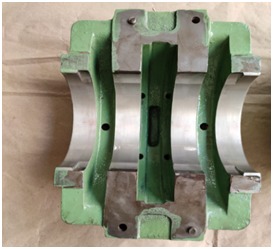

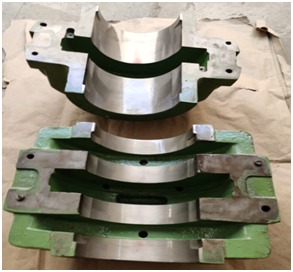

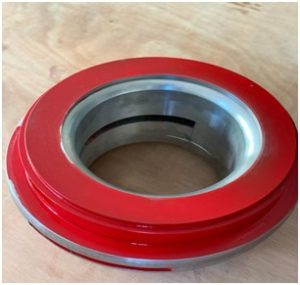

White metal bearings, also known as Babbitt bearings, are designed to provide low friction, high load capacity, and excellent resistance to wear and tear. These bearings consist of a thin layer of white metal, typically made of tin, lead, and antimony, which is bonded to a steel or bronze backing.

White metal bearings are commonly used in applications where heavy machinery operates under extreme conditions, such as in power plants, marine engines, compressors, and industrial equipment.

RA Power Solutions Expertise:

RA Power Solutions is a renowned provider of white metal bearing solutions, offering their expertise to customers in Greece. With a team of highly skilled technicians and engineers, they have the knowledge and experience to deliver reliable and durable white metal bearings in Greece. The company understands the unique requirements of different industries and provides customized solutions that meet specific needs.

State-of-the-Art Facilities:

RA Power Solutions boasts state-of-the-art facilities equipped with modern machinery and tools to manufacture and repair white metal bearings. Their facilities adhere to international quality standards, ensuring that the bearings are produced with precision and accuracy.

Additionally, their advanced infrastructure enables them to handle projects of varying complexities, from small-scale repairs to large-scale manufacturing.

Quality Assurance:

At RA Power Solutions, quality assurance is of utmost importance. The company follows stringent quality control measures throughout the manufacturing and repair processes. Their experienced technicians conduct thorough inspections and tests to ensure that the white metal bearings meet the required specifications and performance standards. By maintaining strict quality control, RA Power Solutions delivers bearings that offer reliable and long-lasting performance.

Repair and Reconditioning Services:

In addition to manufacturing new white metal bearings, RA Power Solutions specializes in the repair and reconditioning of existing bearings. They employ advanced techniques and machinery to restore worn-out bearings to their original condition, saving clients both time and money.

Emergency Services and On Site Support:

RA Power Solutions understands the importance of minimizing downtime in critical machinery. Hence, they offer round-the-clock emergency services to address urgent white metal bearing issues. Whether it’s a breakdown in a power plant or a marine engine failure, their dedicated team is ready to provide immediate assistance.

Moreover, they also offer on site support, dispatching technicians equipped with portable machinery to minimize equipment transportation time and facilitate quick repairs.

Customer Satisfaction:

RA Power Solutions has earned a reputation for its commitment to customer satisfaction. By delivering reliable and efficient white metal bearings, the company has garnered a loyal customer base in Greece. Their customer-centric approach, coupled with prompt and effective services, ensures that clients receive the best possible solutions tailored to their specific needs.

Conclusion:

When it comes to white metal bearings in Greece, RA Power Solutions emerges as a reliable partner for industries across the country. With their expertise, advanced facilities, and commitment to quality, they deliver high-performance white metal bearings that optimize machinery operation.

Whether manufacturing new bearings, repairing existing ones, or providing emergency support, RA Power Solutions is a trusted name in the industry, ensuring the smooth functioning of critical machinery in Greece.

Please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.