Damaged engine parts, construction equipment, and all mechanical equipment can be repaired successfully by metal locking and metal stitching processes in case of cracks or extensive damage to casting due to an accident.

The repair of cracks or damaged casting by using the traditional welding method is not successful for the repair of cast iron and alloy cast metal components.

RA Power Solutions has an expert team of technicians who are trained to execute the repair of cracks and repair of damage casting of large equipment by metal lock surgery and metal locking process.

The repair of cracks by metal lock and metal stitching process has the following advantages:

I) In case of a crack or damaged component, there is no need to send it to the designated workshop. Our technicians visit the site and undertake the repair of cracks by metal locking and metal stitching process.

II) Metal lock and metal stitching is a proven method of repair of cracks. It is a permanent solution, a cold process of crack repair, and no heat is generated as in the case of welding.

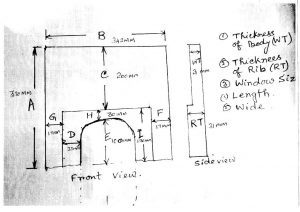

III) In case a large portion of the casting is damaged it is possible to replace it with the new casting having the same design, profile, and metallurgical properties by metal stitching and metal locking.

We have provided services of crack repair and repair of damage casting for the last 4 decades all over the world. We are cost-effective and execute the repairs with a guarantee.

Repair Cast Iron | Metal Lock Surgery | Cast Iron Repair

We undertake cast iron repair by metal surgery process. It is a cold process of crack repair in cast iron, aluminium casting, and cast steel casting. The repair by metal surgery strictly maintains the original alignment and profile as there is no heat produced and no distortion.

Most of the repairs in cast iron are possible without dismantling the damaged component from the main equipment. We use portable pneumatic tools to undertake cast iron repair by metal stitching, metal locking, and metal surgery.

The only company that offers Metal stitching engine block, metal lock surgery, and metal locking services while the vessel is sailing. For more information, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.