RA Power Solutions is the leader in the design, development, and manufacturing of Babbitt white metal bearing up to a diameter of 1500 mm. We export bearings to various countries and supply the bearings to private and public sector industries like maritime, oil and gas sector, power supply industries, and for various applications.

EXPERTISE IN RA POWER SOLUTIONS IN DESIGN DEVELOPMENT AND MANUFACTURING OF WHITE METAL BABBITT BEARINGS:-

- We specialize in reverse engineering. This helps us in the design and development of bearings as per the sample provided by the client.

- The bearings are developed and manufactured according to the drawing submitted by the client.

- The dimension and metallurgical properties of Babbitt white metal are of great importance.

- With our experience in this field, we recommend always using high-grade white metal, this enhances the life of the bearing manifolds.

- In case the bearings are heavy and difficult to transport to our factory, we have a team of experienced engineers who visit your plant all over the world with Cad-cam and instruments.

- Our technicians while staying in your plant prepare the drawing and collect the dimensions required for the development and manufacturing of Babbitt white metal bearings.

- Our services of preparation of drawing of heavy and old bearings are widely appreciated all over the world and have saved a number of equipment which were not in operation due to unavailability of the bearings.

- Technicians with experience ranging from 20 to 40 years are available who very well understand the importance of critical dimensions required at the time of development and manufacturing of Babbitt white metal. The bearings are supplied in finished condition with a guarantee.

- We ensure that the bearings are developed strictly as per the site requirement. We regularly develop small and large bearings up to 1500mm diameter for compressors, diesel engines, high-capacity turbines, Alternators, rotor shafts, gearboxes, pumps, and all applications.

RANGE OF BABBITT WHITE METAL BEARINGS DEVELOPED AND MANUFACTURED BY RA POWER SOLUTIONS:-

We have in-house facilities to machine cylindrical, elliptical, and multi-lobe profiles for our plain journal bearings. We supply tilting pad journal & tilting pad thrust bearings; combined thrust and journal bearings; gearbox spindles; seals and baffles.

Our range of journal and thrust bearings is continuously changing to cover larger and more sophisticated technical products demanded by advanced technology.

BABBITT WHITE METAL LINING:-

We use modern technology for lining white metal on steel casing, the application of the centrifugal casting process backed up by an advanced lining process ensures high-quality white metal bonding.

The bonding of white metal Babbitt to the steel lining is of great importance. This is ensured by multiple-time inspection by ultrasonic and dye penetrant testing. The ultrasonic and dye penetrant testing of Babbitt white metal lining is done at different stages of manufacturing by qualified in-house level 2 NDT technicians.

MANUFACTURER AND EXPORTER OF BABBITT WHITE METAL INGOTS:-

We also manufacture Babbitt white metal ingots in different grades as per the requirement of the client. All the grades of white metal are internationally standardized and the engineers in the industry are aware of the grading of white metal.

We manufacture and supply Babbitt white metal ingots in the grade and size required by the client.

We export Babbitt white metal bearings in countries like Argentina, Bahamas, Barbados, Bermuda, Bolivia, Brazil, Canada, Chile, Colombia, Costa Rica, Cuba, Dominican Republic, Ecuador, El Salvador, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua, etc.

RA Power Solutions has played a pivotal role in advancing the field of engineering with its remarkable development of white metal Babbitt bearings.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.). He is a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy, and Shipping industries. He is a Technical Adviser to many shipping and heavy industries across the globe.

He is one of the most enthusiastic professionals and he has all the brilliance of an exemplary leader. He is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more information on bearing manufacturing company, white metal bearing alloy in ingot form, or development of white metal babbitt bearing, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Visit our website: http://rapowersolutions.com/

Image Gallery

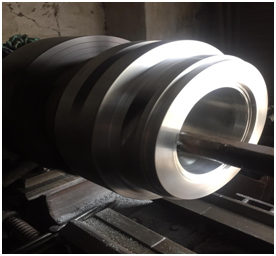

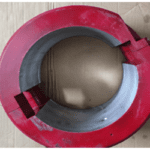

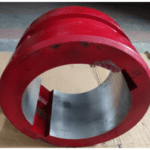

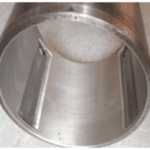

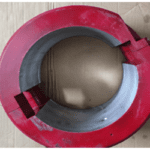

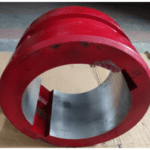

Old Bearing of Turbine before White Metal Bearing after

Rebabbitting and Repair Rebabbitting

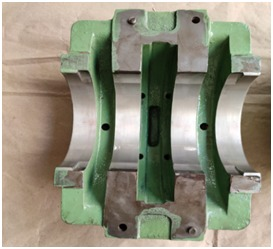

Thin Shell Type White Metal Crankpin Bearing

Bearing

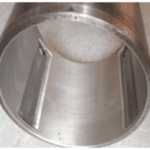

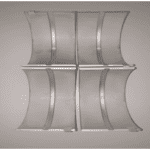

White Metal Babbitt Bearing Babbitt White Metal Bearing

Repair after Rebabbitting