Crack Repair By Metal Stitching | Advantages Of Metal locking And Metal Stitching

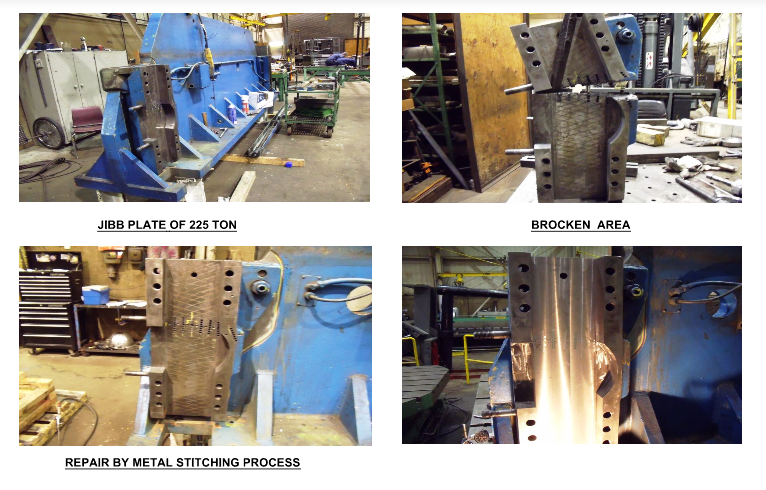

RA Power Solutions Pvt. Ltd. undertakes the repair of cracked castings and castings broken into pieces using the metal stitching and metal locking process. The company has executed the repair of more than 600 nos. of cracked engine blocks, cast iron cold metal stitching, turbine casing, turbocharger casings, gearbox housings, etc. in the last 4 decades.

It is proven that the repair of cracks in cast iron or cast steel castings is successful by metal stitching and metal locking process in comparison to the old welding process that was followed.

The advantages of crack repair by metal stitching and metal locking process are as follows:

- Metal stitching and metal locking processes repair cracks in engine blocks, cylinder heads, and turbines on-site without disassembling the equipment. This process of repair saves downtime and is cost-effective.

- The metal locking and metal stitching process provides an excellent expansion joint for engine parts such as cylinder liners, crankcases, and cylinder heads, which are subject to thermal and mechanical stresses. The main advantage of repairing cracks using the metal stitching and metal locking process is that the process develops no stresses and maintains alignment with the original surfaces because it produces no heat and causes no distortion.

- The procedure and process of repair of cracks by metal stitching and metal locking are accepted by various classes and inspection agencies.

- The process of metal locking and metal stitching is cold, no heat is generate and in most cases, there is no need to replace heavy and expensive parts.

Metal Stitching Of Engine Block

RA Power Solutions Pvt. Ltd. undertakes the repair of cracked or damaged engine blocks using metal locking, metal stitching, and the metal surgery process. It is possible to repair damaged or cracked engine blocks on-site that are manufactured from the following base metals.

- Cast steel

- Aluminium casting

- Ductile iron

- Cast iron

With the introduction of modern technology and processes. Welding does not suit the repair of cracks in heavy-duty cast iron components because the welding process generates heat and unwanted stresses. It cause serious damage to the cast iron components.

The engine block repair by metal locking, metal stitching of the engine block, and the metal surgery process is a proven method of repair of cracks or damaged heavy components.

For more information on the Metal lock and metal stitching, metal locking process, metal stitching of castings, and metal stitching of engine block and cold metal stitching, crack repair by metal stitching, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

Metal stitching is a cold crack repair method that uses interlocking metal keys and locks to restore cracked or broken castings without heat.

Unlike welding, metal stitching produces no heat, meaning no distortion, no residual stresses, and often a stronger final result.

Yes, one of the biggest advantages is that metal stitching can be complete in-situ, reducing machine downtime and logistical costs.

Metal stitching works effectively on cast iron, cast steel, aluminium, and other alloys commonly used in heavy machinery.

Yes, when properly done, the repaired component often achieves structural integrity equal to or better than the original, including pressure-tight sealing where needed.