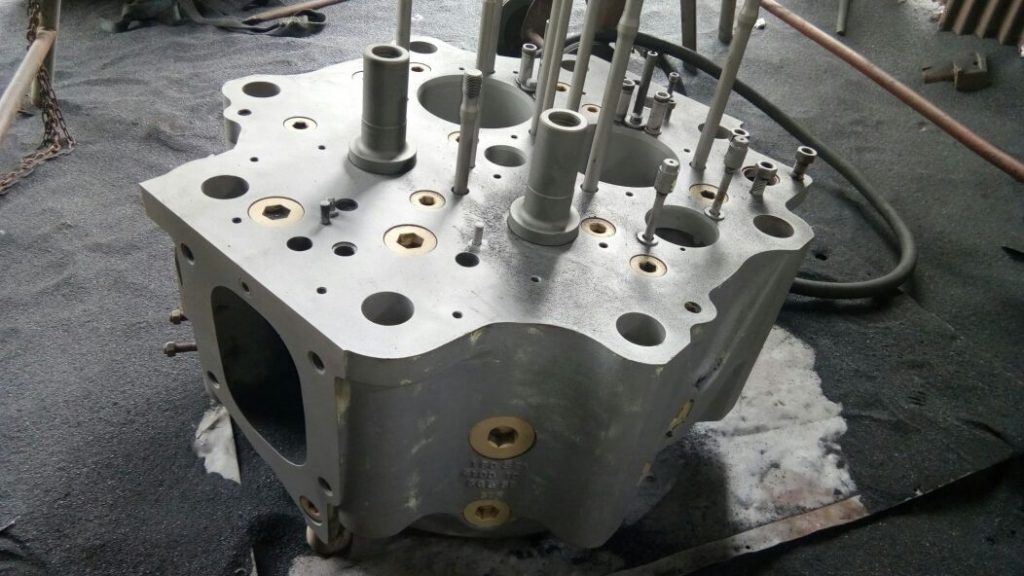

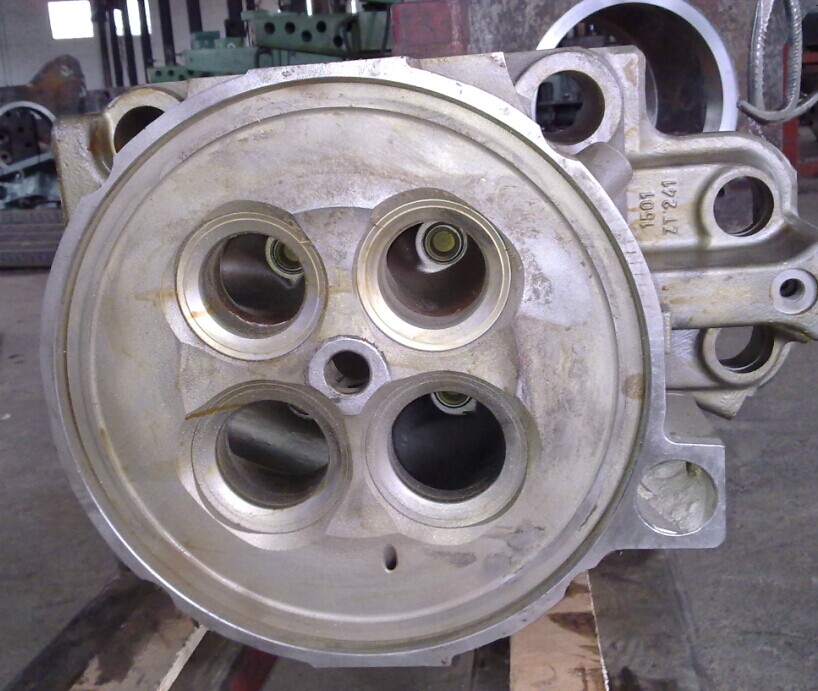

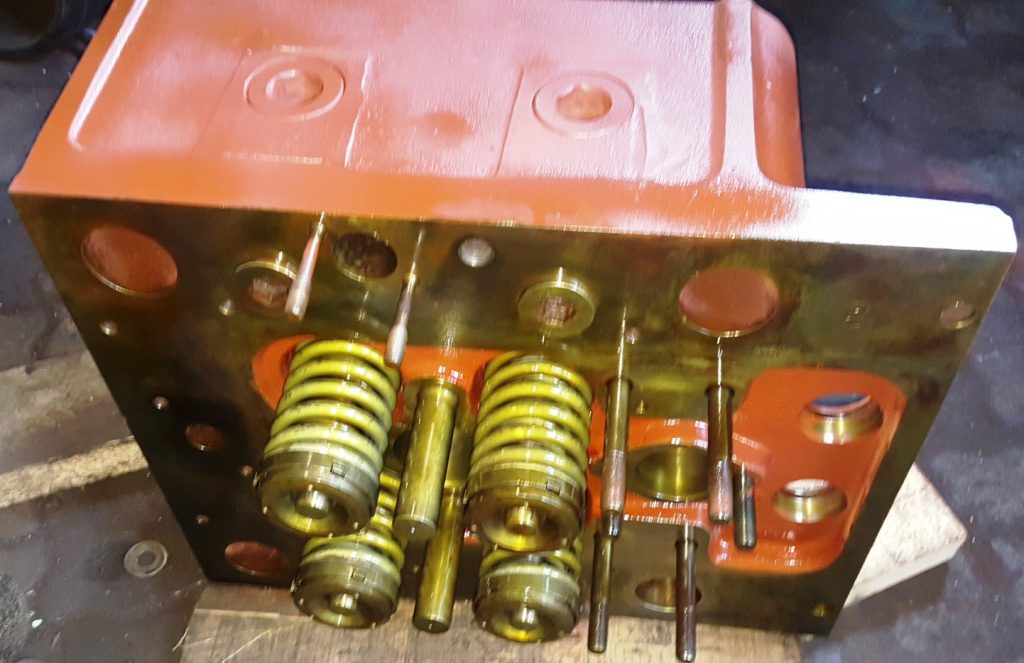

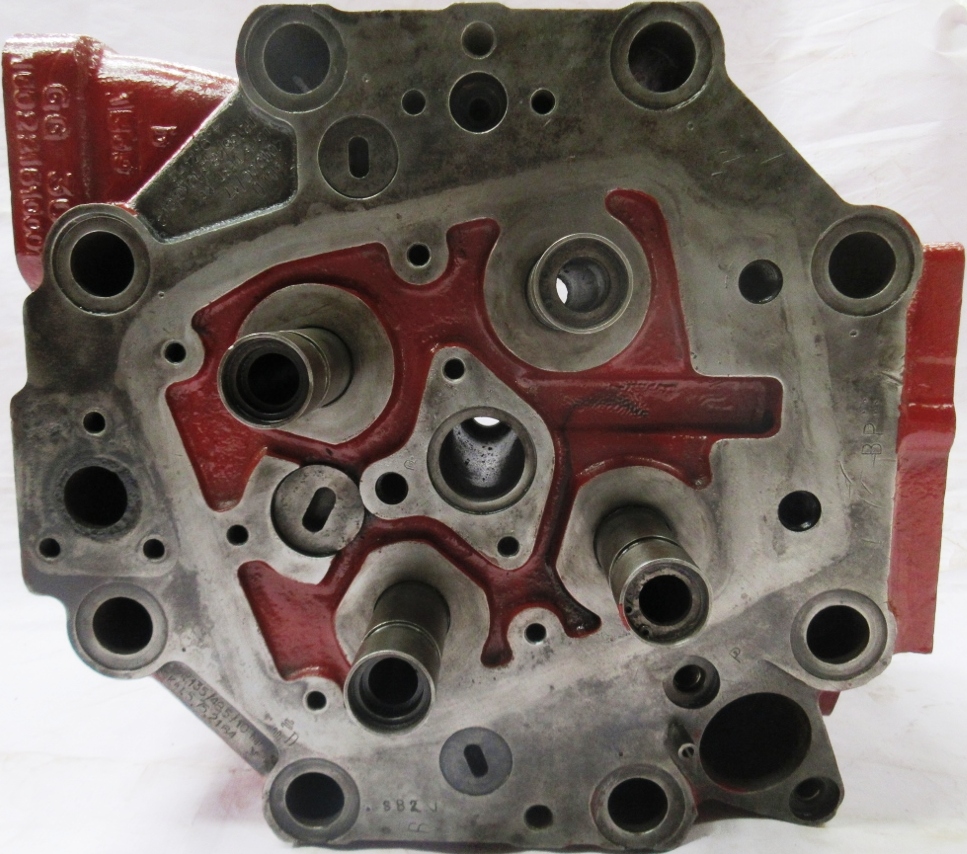

Reconditioned cylinder heads are available in stock and ready for dispatch for high-capacity diesel engines. RA Power Solutions is a leading reconditioned cylinder head refurbishing company supplying fully reconditioned cylinder heads directly to end users all over the world.

Cylinder heads are refurbished in-house by experienced technicians. The guidelines and technical specifications recommended by the manufacturers are strictly followed. Cylinder heads complete in all aspects, and ready to install are supplied. Each cylinder head passes through the strict quality control inspection process and all the reports are documented. The crack detection by MPI process is undertaken before reconditioning of the cylinder head and after the cylinder head is refurbished.

RA Power Solutions also undertakes a pressure test of each cylinder head after refurbishing. The pressure is maintained more than the prescribed limit of the manufacturer. We stand a guarantee for the satisfactory performance of the refurbished cylinder head.

With our experience of four decades, we have supplied over 5000 reconditioned cylinder heads all over the world and are considered to be the lowest in price.

We supply cylinder heads for the following diesel engines with a guarantee: B&W, Bergen, Daihatsu, Deutz, Caterpillar, MAK, Man, MTU, MWM, Nohab, Mirrlees Blackstone, Pielstick, Stork, Stork Werkspoor, Sulzer, Wartsila, Yanmar, Niigata, Cummins, Detroit Diesel, Perkins, etc.

For more information, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.