Manufacturing of White Metal Babbitt Bearings has been undertaken for all applications for over 40 years. The development and manufacturing of White Metal Babbitt Bearing as per the customer drawing or as per the sample have been the core of the business all these years. We have developed successfully hundreds of White Metal Babbitt Bearings as per a drawing or a sample. These bearings were discontinued by the original manufacturer.

It is experienced that due to changes in technology, the large integrated engineering plants in areas like cement, fertilizer, chemical, and steel are discontinued by the manufacturers. In this situation, RA Power Solutions has an important role to play by successfully developing the bearings and keeping the plant in operation. We have the approval as manufacturers and suppliers of various private and public sector companies in engineering, defense, and maritime, oil and gas, etc.

Remetalling of Alternator Bearing

Wide range of White Metal Bearing Manufactured:

- We can manufacture bearings up to 1500 mm in diameter.

- All the bearings are manufactured by the centrifugal babbitting process.

The new bearings and repair of old bearings are undertaken for various machines including the following:

- Rotary Kilns

- Turbines

- High-Speed Compressors

- Gearboxes

- Boiler Feed Pumps

- Generators

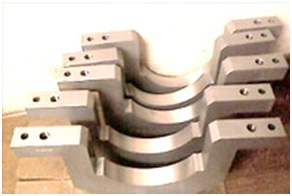

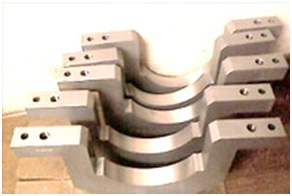

White Metal Babbitt Bearing Under Inspection

White Metal Bearings are repaired by us. We undertake the repair of the following bearings:-

- Stern Tube Bearings

- Journal Bearings

- Thrust Bearings

- Slide Shoe Bearings

- Trunnion Bearings

- Tilt Pad Journal Bearings

- Pedestal Bearings

- Self-leveling Thrust Bearings

Babbitt White Metal Bearing Under Machining Process

An inspection procedure was followed at the time of rebabbitting of old white metal bearings.

- White metal from the old bearing is removed at a controlled temperature.

- A metallurgical test of existing Babbitt white metal is undertaken.

- The steel shell of the old white metal Babbitt bearing is shot blasted.

- Surface hardness is checked for the presence of any hard spots.

- Crack detection by MPI and the dye-penetrant test are done.

- After the Rebabbitting process, the above inspection procedure is repeated.

- Ultrasound of white metal Babbitt bearing after repairs is of great importance to check the bonding.

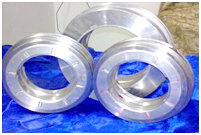

Babbitt White Metal Turbine Bearing Ready for Dispatch:-

This is done by our experienced level-3 qualified technicians.

Conclusion: White metal by nature is delicate and needs to be handled with care. We pay extra attention to the packing of new white metal bearings and the bearings that have been received by us for repairs.

For more information on white metal bearings and Daihatsu engine bearing suppliers, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.