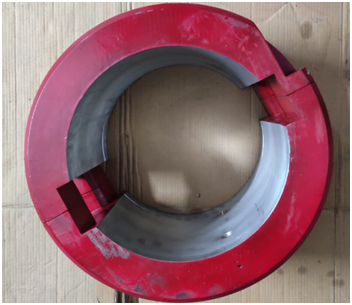

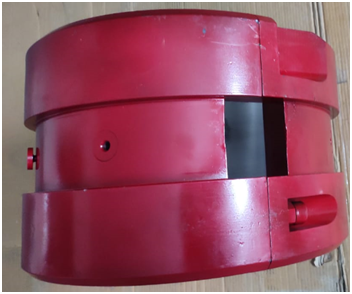

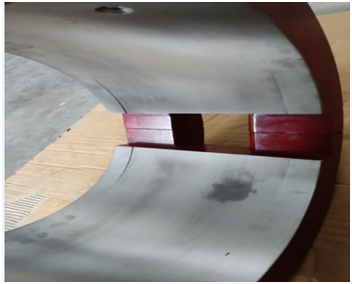

RA Power Solutions is a leading engineering company providing onsite machining and grinding of the crankshaft of diesel engines, compressors, pumps, etc.

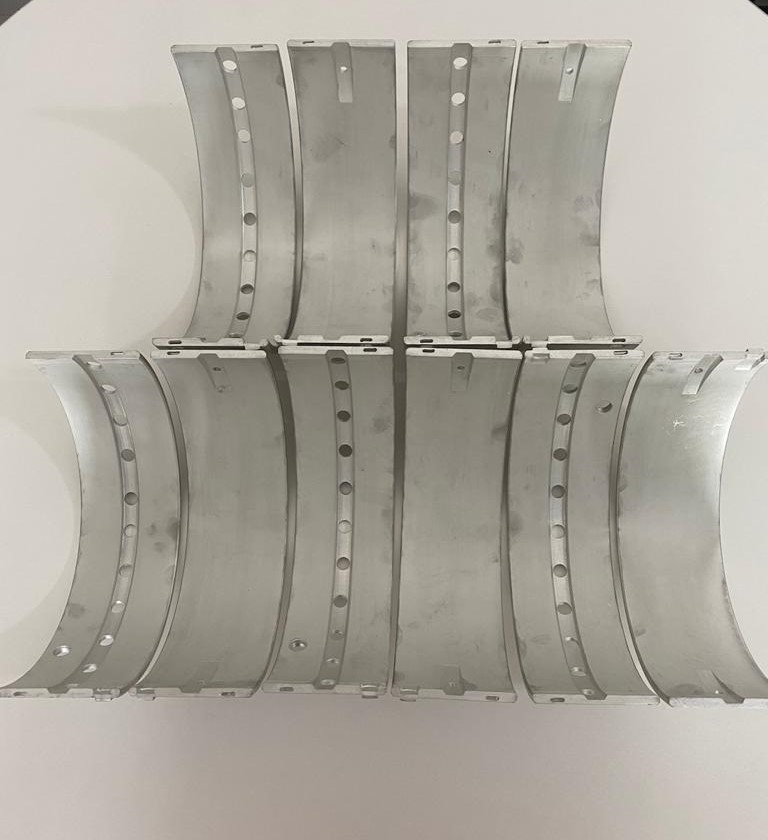

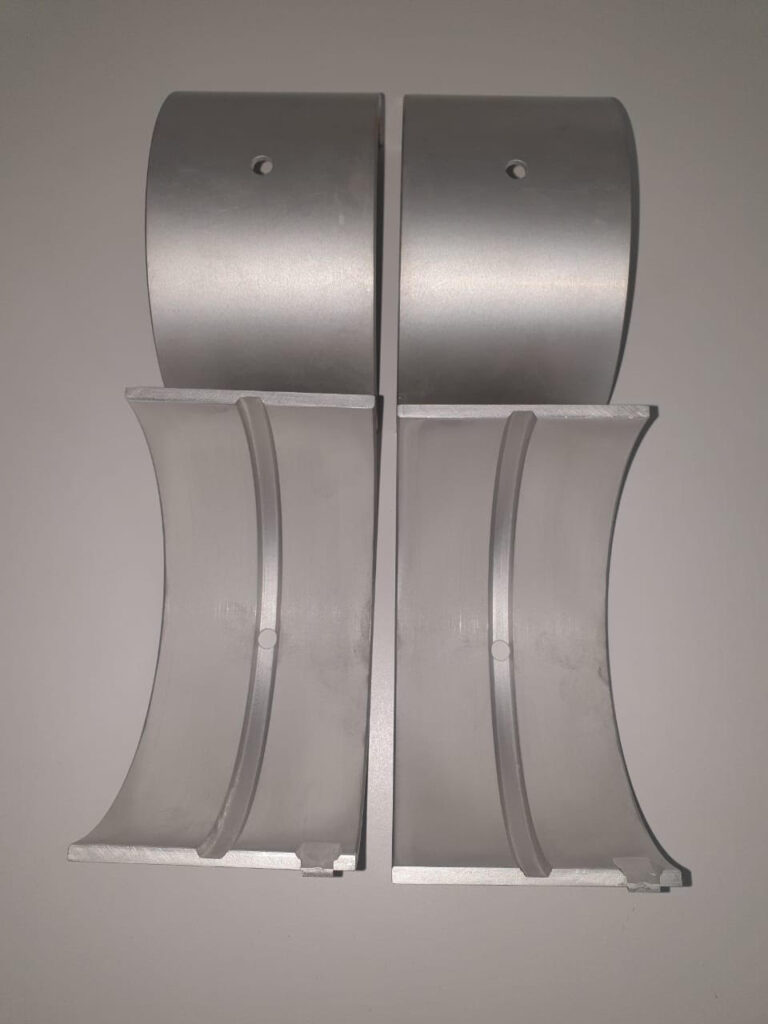

The requirement of undersize bearings in the case of auxiliary engines and marine engines after grinding is obvious, it is experienced that the crankpin & main journal bearings of popular make of engines are not available ready in stock most of the time from the Engine manufacturer.

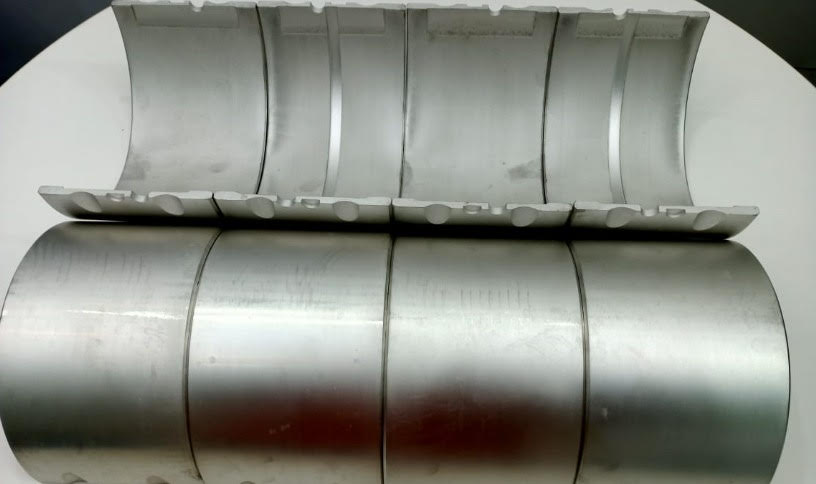

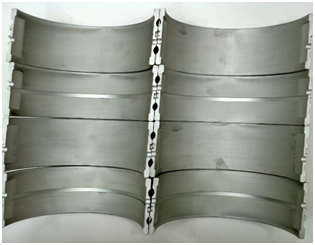

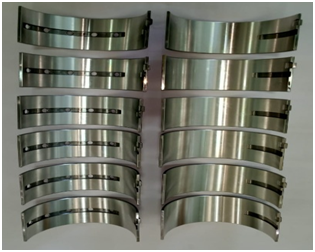

RA Power Solutions maintains the stock of standard/ undersize crankpin bearings and main journal bearings for the reputed make & model of engines like B&W, Daihatsu, Deutz, MAK, MAN, Yanmar, Sulzer, Compressor, CKD Skoda and Allen, etc.

We are giving below a sample list of the bearings of the crankpin and main journal which are available with us in stock. A complete list of crankpin and main journal bearings available with us can be shared on request.

| Sr. No | Description | Qty |

|---|---|---|

| 1 | MAN CME 5L 16/24 Standard Crankpin Diameter- 130 mm | |

| a) 0.5 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 1.0 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 1.5 mm Undersized Crankpin Bearing | 8 pairs | |

| d) 2.0 mm Undersized Crankpin Bearing | 8 pairs | |

| e) 2.5 mm Undersized Crankpin Bearing | 8 pairs | |

| f) Main Journal Bearings | 8 pairs | |

| 2 | Daihatsu 5DK20 Standard Crankpin Diameter-170 mm | |

| a) 0.5 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 1.0 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 1.5 mm Undersized Crankpin Bearing | 8 pairs | |

| d) 2.0 mm Undersized Crankpin Bearing | 8 pairs | |

| e) 2.5 mm undersize Crankpin Bearing | 16 pairs | |

| f) Main Journal Bearings | 8 pairs | |

| 3 | Daihatsu 5DC17 Standard Crankpin Diameter-145 mm | |

| a) 0.5 mm Undersized Crankpin Bearing | 14 pairs | |

| b) 1.0 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 1.5 mm Undersized Crankpin Bearing | 8 pairs | |

| d) 2.0 mm Undersized Crankpin Bearing | 8 pairs | |

| e) 2.5 mm Undersized Crankpin Bearing | 8 pairs | |

| f) 3.0 mm Undersized Crankpin Bearing | 8 pairs | |

| g) Main Journal Bearings | 8 pairs | |

| 4 | Yanmar Engine 6N18AL-DN/DV Standard Crankpin Diameter-145 mm | |

| a) 0.40 mm Undersized Crankpin Bearing | 14 pairs | |

| b) 0.80 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 1.60 mm Undersized Crankpin Bearing | 8 pairs | |

| d) 2.0 mm undersized Crankpin Bearing | 8 pairs | |

| e) 1.20 mm undersized Crankpin Bearing | 8 pairs | |

| 5 | Yanmar Engine –S 185 L Standard Crankpin Diameter-140 mm | |

| a) 0.8 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 1.2 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 1.60 mm Undersized Crankpin Bearing | 8 pairs | |

| d) 2.0 mm Undersized Crankpin Bearing | 8 pairs | |

| 6 | MAN 9ASL 25/30 Standard Crankpin diameter-195 mm | |

| a) 2.5 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 3.0 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 4.0 mm Undersized Crankpin Bearing | 6 pairs | |

| 7 | Allen Engine PVBCS12 F Standard Crankpin diameter – 190.40 mm | |

| a) 0.5 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 1.0 mm Undersized Crankpin Bearing | 8 pairs | |

| 8 | Gas Engine Deutz MWM TBG32V16 Standard Crankpin diameter 204.50 mm | |

| a) 0.5 mm Undersized Crankpin Bearing | 8 pairs | |

| 9 | Daihatsu Model 8DKM28 Standard Crankpin diameter-235 mm | |

| a) 0.5 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 1.0 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 1.5 mm Undersized Crankpin Bearing | 8 pairs | |

| d) 2.0 mm Undersized Crankpin Bearing | 8 pairs | |

| e) 2.5 mm Undersized Crankpin Bearing | 8 pairs | |

| f) Standard size Bearing | 8 pairs | |

| 10 | Daihatsu Model 6DL-16 Standard Crankpin diameter-120 mm | |

| a) 2.0 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 2.5 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 3.0 mm Undersized Crankpin Bearing | 8 pairs | |

| 11 | MAK MODEL 8M20 Standard Crankpin diameter-152 mm | |

| a) 2.0 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 2.5 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 3.0 mm Undersized Crankpin Bearing | 4 pairs | |

| 12 | MAN 6L 23/30H Standard Crankpin diameter-185 mm | |

| a) 1.5 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 2.0 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 2.5 mm Undersized Crankpin Bearing | 8 pairs | |

| 13 | CKD Skoda 638A6S 2270 KVA Standard Crankpin diameter 280 mm | |

| a) 0.5 mm Undersized Crankpin Bearing | 12 pairs | |

| b) 1.0 mm Undersized Crankpin Bearing | 12 pairs | |

| c) 1.5 mm Undersized Crankpin Bearing | 12 pairs | |

| d) 2.0 mm undersized Crankpin Bearing | 12 pairs | |

| 14 | Cummins Model QSV 91G | 8 pairs |

| 15 | Ariel Compressor JGH/4 stroke 4.5 inch | |

| a) 0.5 mm Undersized Crankpin Bearing | 8 pairs | |

| b) 1.0 mm Undersized Crankpin Bearing | 8 pairs | |

| c) 1.5 mm Undersized Crankpin Bearing | 8 pairs | |

| 16 | Ariel Compressor JGH/4 stroke 4.5-inch Main Journal | |

| a) standard size Main Journal Bearing | 8 pairs | |

We export Trimetal engine bearings and Babbitt white metal bearings in countries like Iraq, Iran, Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, Fujairah, Bahrain, Kuwait, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Malaysia, Indonesia, Madagascar, Vietnam, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, South Korea, Saint Vincent, and the Grenadines, Trinidad, and Tobago, etc.

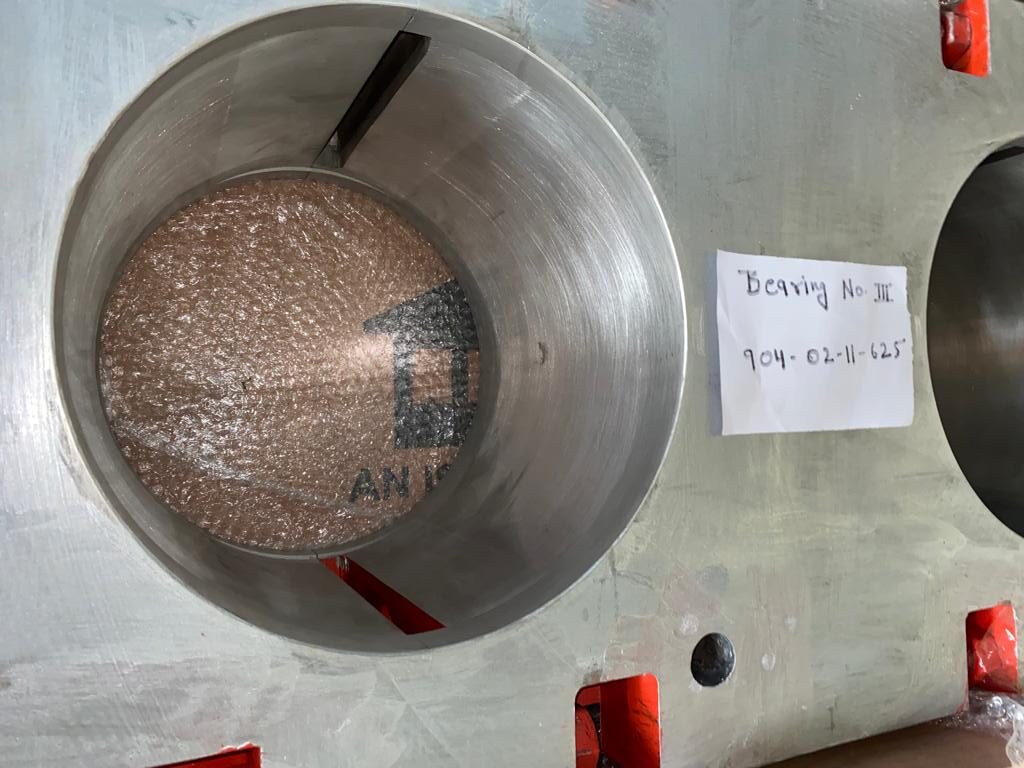

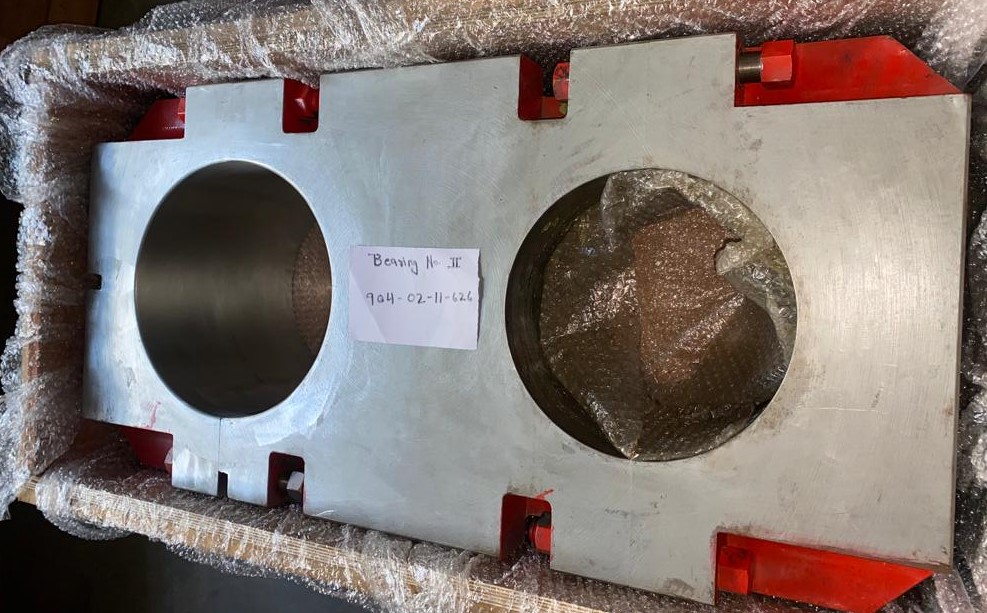

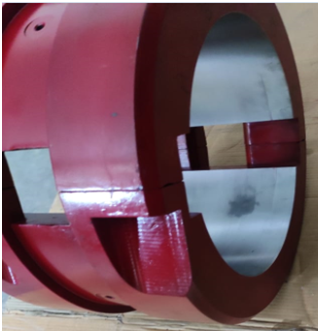

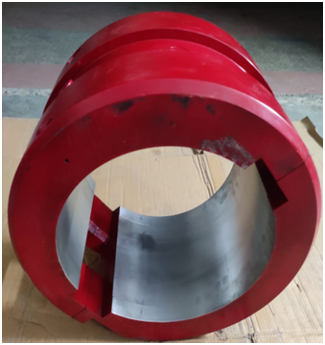

Bearing Manufacturer: RA Power Solutions

Discover precision and quality with RA Power Solutions – Your trusted bearing manufacturer! Elevate your machinery’s performance with our top-notch bearings. From custom designs to off-the-shelf solutions, we offer a comprehensive range to meet your specific needs. Boost productivity, reduce downtime, and enhance reliability. Explore our bearings today!

For more information on engine bearing manufacturers, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.