Introduction: Cast iron is a versatile and durable material used in various industries due to its excellent strength and heat resistance. However, over time, cast iron components can develop cracks, compromising their structural integrity and functionality.

To address this issue, metal surgery techniques can be employed to repair and restore cast iron parts effectively. In this article, we will delve into the world of cast iron crack repair, exploring different methods, best practices, and the importance of professional expertise.

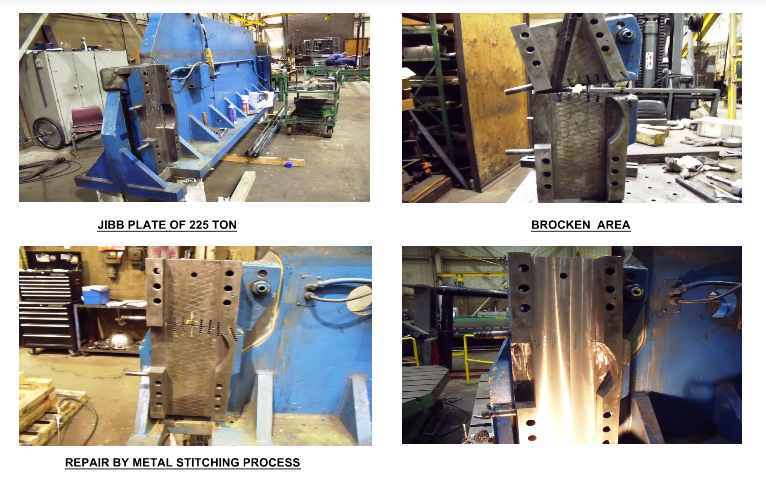

We were approached by a leading shipping company operating in the Middle East. One of their auxiliary engine model Daihatsu 6DK20 met with an accident and the engine block window on which the cover is fixed was broken into pieces due to the failure of the connecting rod bolt.

RA Power Solutions Pvt. Ltd was appointed and we called for the photographs of the broken area of the engine block with dimensions which are pasted below.

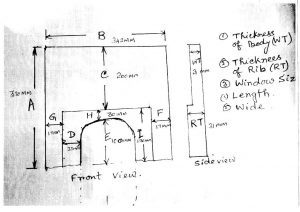

A rough drawing of the engine block broken area which is of cast iron was prepared by RA Power Solutions Pvt. Ltd. technicians as below.

Since the time was short, we manufactured a casting measuring 15 x15 inches and 2 technicians boarded the vessel. The job of repairing of cast iron engine block was executed in a recorded minimum time. The engine is performing satisfactorily.

We have all the latest tooling available for repair of cast iron, and parts of the diesel engine to the original shape and profile. The metal stitching and metal locking process followed by us to repair the cast iron gives more strength than the original casting.

Cast iron crack repair requires a skilled approach, tailored to the type and severity of the cracks present. By employing metal surgery techniques like cold stitching, metal stitching, fusion welding, brazing, and stress relief heat treatment, it is possible to restore the functionality and structural integrity of cast iron components.

If you encounter cracked cast iron machinery or parts, consult us. We are professional metallurgical experts specializing in cast iron crack repair services, ensuring the best possible outcome.

To know more about metal stitching, cast iron crack repair, and metal surgery, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.