RA Power Solutions having more than forty years of experience in the field of repair and maintenance of high-capacity engines understands the importance of the parts.

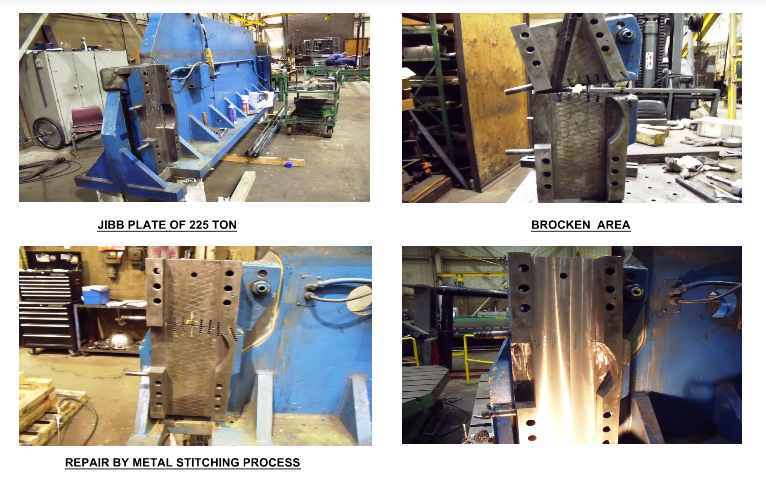

In case of damage to engine components or cracks, RA Power Solutions undertakes repair onsite by metal stitching or metal lock surgery. We are considered to be the leaders in this field as we use the master lock, masterpiece, keys and consumables of high quality imported from the UK.

Our technicians are highly experienced. Crack repair and repair of damaged casting components can also be executed while sailing the Vessel.

Following is the process of metal locking, metal stitching, and its advantages.

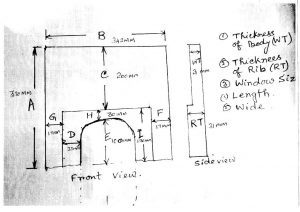

Process of Metal Locking, Metal Stitching:

The Metal Stitching process is accepted as the method of repairing all cracked, broken and damaged casting in cast iron, aluminium and steel.

The Stitching Process:

- At first, visible and invisible cracks are identified.

- The parts are clamped together to bring the parts to their original position.

- A rectangular hole is made across the fractured portion.

- This hole is made by drilling and chipping.

- The Master lock, a large rectangular key of special metal is inserted into the hole.

- Locking Pins are inserted alongside the master lock to provide a tight and secured master lock.

- A length of metal stitching keys is inserted on the sides of the master lock to prevent the locking pins from falling out when the casting is subjected to high vibrations.

Advantages of Metal Stitching:

- No heat stress is induced

- No Distortion occurs

- In many instances, machining is not required

- Invaluable in emergencies

- Reduces downtime

- Gas/ Liquid proof repair

Crack Repair in Grey Cast Iron | Aluminium and Cast Steel Components

It is observed that due to accidents or continuous running of the engine cracks develop in grey cast iron, aluminium, and Cast Steel Components. There is no need for disassembly of the equipment and getting it repaired by the welding process. We undertake the repair of cracks and badly damaged components by metal stitching and metal lock surgery process.

This method of crack repair is proven and is widely used all over the world. The services of crack repair in Grey Cast Iron, Aluminium and Cast Steel Components by metal stitching and metal locking are extended by us worldwide on a 24*7 basis.

We have a dedicated team that undertakes crack repair of cast iron and repair of damaged casting. Special pneumatic tools, locks and keys are used to execute the repairs. All the jobs of crack repair in Grey Cast Iron, Aluminium and Cast Steel Components executed by us are guaranteed for satisfactory performance.

We extend metal stitching services all over the world including countries like Brazil, Egypt, Panama, Russia, Argentina, Ecuador, Czech Republic, Senegal, Fiji, France, Germany, Dubai, Kenya, Chile, and Mexico.

For more information on metal lock surgery, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.