Crankpin and Main Journal Engine Bearings

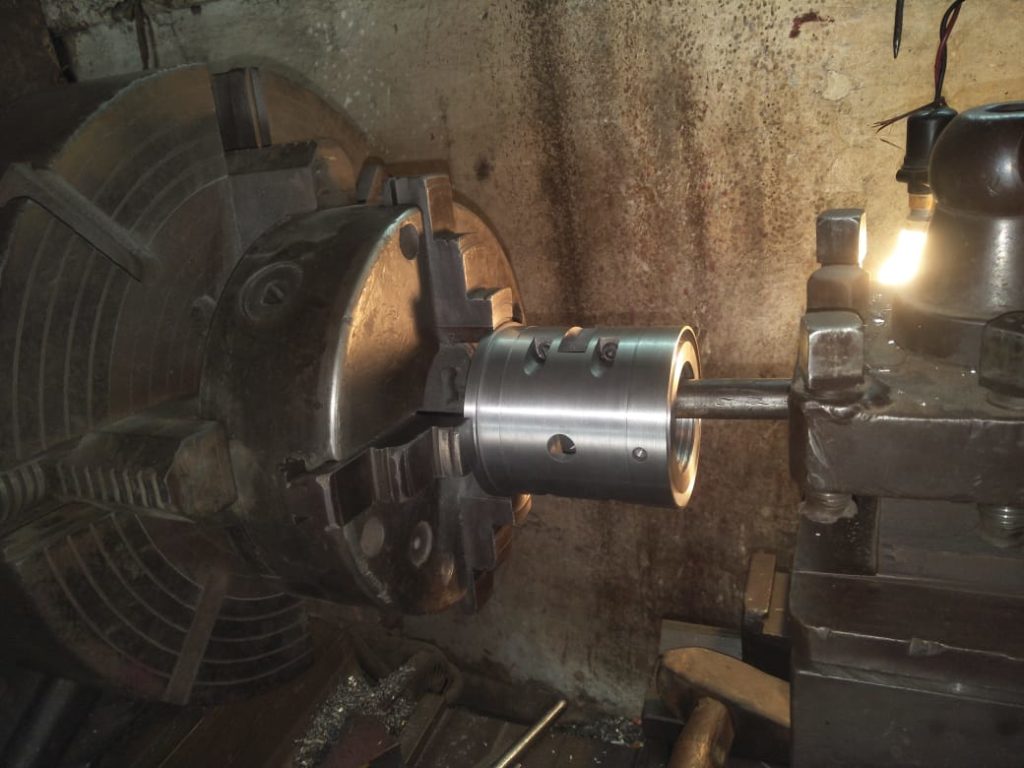

RA Power Solutions undertakes onsite repair of the crankshaft of main and auxiliary engines installed on vessels and high-capacity engines used for various applications. The crankshaft repair is undertaken by the use of specially designed portable, compact, and lightweight onsite crankshaft grinding machines which are designed, developed, and manufactured by RA Power Solutions.

It is obvious that after grinding of crankpin and main journal of the crankshaft there is a requirement for undersize bearings. It is generally observed that the undersize bearing for the crank pin and main journal of engines are not readily available to the manufacturers of Engines and their agents. RA Power Solutions maintains a large stock of undersize bearings for crankpins and the main journal of the main engine and auxiliary engines of all popular makes and models that are installed on the vessel.

The bearings are imported from Japan and Europe. The ready availability of bearings reduces the downtime of the engine. All the main journal and crankpin bearings supplied by RA Power Solutions are guaranteed satisfactory performance for 2500 hrs of operation or 12 months from the date of dispatch.

We maintain the stock of bearings for the following engines:

Wartsila , Daihatsu , MWM , Caterpillar , MaN , MaK , B&W , Sulzer , Bergen , Detroit Diesel , Stork Werkspoor , Pielstick , Deutz , Yanmar , MTU , Cummins , Nohab Polar , Caterpillar , Mitsubishi , Yanmar , MaK 551 , MaK 552 , MaK 453 , MaK 451 AK , MaK 452 AK , Deutz 540 , Deutz 358 , Deutz 350, Pielstick PC 2.2 PC 2.5, Wartsila 524 ,Wartsila 824 TS, Sulzer 6 AL 25/30, Sulzer 5 AL 25/30 MWM TBD 484, MaN 40/54 , MaN Sulzer 12 ASV 25/30 , Sulzer 16 ZV 40/48 , Deutz BV 16M 540 , B&W 6L 45 GFCA, MAN B&W 55/GF, CAT D353, B&W 5T23LH, Daihatsu 6 PST 26D, Daihatsu 6 PSHTb 26M, Mak 6MU 451 AK, Deutz 6M 628, Caterpillar 3512, Deutz BV 12M 628, MWM TBD 234, WICHMANN 5AX, SKL 8NVD 48A-2U, Pielstick PC 2.2 LNR, Caterpillar 3508 and more.

As a repairer of crankshafts having experience of more than forty years in this field, we have come across a situation where the crank pin or main journal diameter is to be reduced more than the last limits specified by the manufacturer. In this situation, the user has no option but to reject the crankshaft and purchase the new crankshaft, the cost of which is exorbitant and the procurement period is long.

RA Power Solutions can manufacture and supply bearings of sizes that are beyond the manufacturer’s last undersize recommended in the maintenance manual. The supply of these special-size bearings like bearings for the Yanmar engine helps to save the crankshaft from rejection.

The grinding of the crankshaft, supply of special-size bearings, and commissioning of the engine are done under the same roof by RA Power Solutions and all the jobs are executed with guaranteed satisfactory performance.

For more information regarding bearings for the Yanmar engine, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.