Introduction:

Large diesel engines are the powerhouses that drive a wide range of industries, including marine, oil and gas, power generation, and heavy machinery. Over time, these robust engines may require repair and overhaul to maintain optimal performance and extend their operational lifespan.

In this blog post, we will delve into the world of large diesel engine repair, exploring the key aspects, challenges, and best practices involved in overhauling these mighty mechanical workhorses.

Auxiliary Diesel Engine Repair

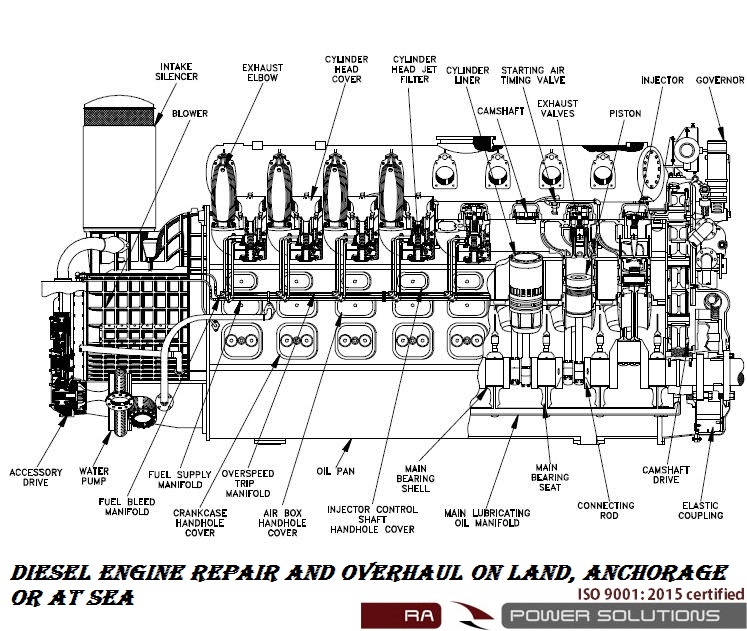

RA Power Solutions undertakes high-capacity diesel engine repairs and overhauls onsite. We are perhaps the only company in the world that has in-house facilities to undertake grinding of the crankshaft, metal stitching and metal locking of engine parts, and repair of all major engine components.

We can undertake the diesel engine overhauling, periodic maintenance, and replacement of the crankshaft while the vessel is sailing. All our technicians possess seaman passports which allow them to board the vessel from one port and disembark at a different port.

The company has more than 37 years of experience in undertaking Main and auxiliary large diesel engine repairs and providing overhaul services. Technicians are available at short notice and can travel anywhere in the world. We can meet any emergency breakdown requirements of the main engine and generators.

Since we have in-house facilities for the repair of engine components technicians carry with them the necessary equipment to calibrate all important parts of the diesel engine at the time of overhauling like calibration of the crankshaft, engine block main journal housing, connecting rods, cylinder liners, cylinder heads, etc.

All the clearances are maintained strictly as per the manufacturer’s recommendations. The load trial of the engine is given after the repair and overhauling of the diesel engine is executed.

Conclusion:

Large diesel engine repair and overhaul are essential to ensure the continued performance and reliability of these formidable machines. By following proper diagnostic procedures, utilizing expert knowledge, and using genuine parts, it is possible to restore these engines to their optimal condition. Regular maintenance and service planning can further enhance the lifespan of large diesel engines, minimizing costly repairs and maximizing productivity in various industries.

Remember, when it comes to large diesel engines, preventive measures, timely repairs, and professional expertise are the keys to maintaining their power and efficiency for years to come.

Author: The author of this blog is Mr. Raj Shahani, Managing Director of RA Power Solutions. He is having experience of almost four decades of working on high-capacity diesel engines, turbines, and rotary equipment. The company specializes in executing the repairs and overhauling of high-capacity diesel engine and their spares.

For more information on engine overhauling, large diesel engine repair, onsite engine overhauling, marine, and auxiliary engine crankshaft repair, and engine repair services, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.